City in Central Federal District

Further information about the population structure:

| Gender (C 2021) | |

|---|---|

| Males | 157,683 |

| Females | 203,961 |

| Urbanization (C 2021) | |

|---|---|

| Urban | 361,644 |

- Ivanovo with places

- Ivanovo city

Located in:

- Ivanovo Oblast

Design of Rock Support in Low Overburden and Hard Rock Conditions with the use of Rock Mass Classification Systems and Numerical Analyses: a Study Based on the Construction of the Hestnes Railway Tunnel, Norway

- Original Paper

- Open access

- Published: 26 August 2024

Cite this article

You have full access to this open access article

- Jorge Terron-Almenara ORCID: orcid.org/0000-0001-7466-5732 1 ,

- Erlend Skretting 2 &

- Karl Gunnar Holter 2

Engineering rock mass classifications are used to describe rock masses and to assist in the design of rock support in hard rock tunneling. In most of the encountered geological- and rock mechanical conditions, from hard and competent rock to poor and fractured rock masses, the application of classification systems has normally resulted in successful and economic designs. However, complex ground conditions as these derived from tunneling in low rock overburden pose several challenges to rock mass classification and support design. In the present study, an analysis of the ground behavior and tunnel stability in a portion with very low rock overburden during the construction of the Hestnes railway tunnel (Norway) was conducted to investigate the performance of the current classification practice for tunnel rock support design. The results have revealed several challenges, which are related to conservative rock mass and rock support assessments due to the lack of consideration of the important stabilizing effect that rock arching has on tunnel stability. It was also found that with the application of an integrated methodology able to combine classification methods with numerical simulations and detailed information of the ground properties and behavior, more optimal designs in the form of rock reinforcement with bolts and shotcrete can be achieved when rock mass quality Q < 1. On this basis, a set of design recommendations was developed for the integration of classification systems with more elaborated engineering design analyses to provide guidance in design optimization for hard rock tunnels subject to low overburden.

Classification systems present limitations to describe rock masses and address rock support in low overburden and hard rock tunneling conditions.

The current practice for assessment of rock mass and rock support in low overburden tunneling conditions in Norway is conservative.

Rock arching can develop in hard and low overburden tunneling conditions and stabilize the ground with the contribution of rock reinforcement.

The integration of rock mass classification with numerical analysis and ground characterization contributes to optimal rock support designs.

Avoid common mistakes on your manuscript.

1 Introduction

Low overburden challenges in hard rock tunnel construction can occur in a number of situations, such as close to the tunnel portals, tunnel crossings, urban tunneling, or due to geometrical constraints imposed by the tunnel alignment and the topography. As a result of the low overburden conditions, the level of stress confinement is usually reduced if compared to that of tunnels located deeper into the rock mass. The latter can lead to gravity-induced failures and more complex failure mechanisms in the rock mass (Hoek and Brown 1980 ; Töyrä 2004 ), as opposed to confined rock masses where the resulting stresses acting perpendicularly on the joint surfaces produce a beneficial stabilizing, interlocking effect.

As the complexity of the ground behavior and failure mechanisms in low overburden tunnels increases, rock mass classification and support design also become more challenging. Remarkably, any substantial update or elaborated design recommendation has been provided in the relevant guidelines that apply for permanent rock support design in Norwegian tunnels. Basically, the rock support design in low overburden tunnels in Norway is based on empirical classification systems as recommended in design guidelines developed by the Norwegian Public Roads Administration (NPRA). Such approach has apparently given acceptable results during the last decades. However, the recent construction of a ~ 100 m long tunnel section in low rock overburden conditions (0.5–1 D where D is tunnel span) in the Hestnes railway tunnel (Fig. 1 ) in southern Norway has revealed some important limitations regarding conservative design practices of tunnel rock support.

Low– overburden tunneling conditions (~ 6–7 m) in hard and competent rock masses at the South portal of Hestnes tunnel (Kleverud area), Norway. Tunnel span is 14 m. The photo is taken towards North. Courtesy of the Norwegian Railway Administration (Bane NOR)

Some of the limitations of classification systems have been thoroughly discussed in the rock engineering literature. Among others, in Bieniawski ( 1988 ), Riedmüller and Schubert ( 1999 ), Stille and Palmstrom ( 2003 ), Palmstrom and Broch ( 2006 ), Vibert and Vaskou ( 2011 ), Bertuzzi ( 2019 ), Høien et al. ( 2019 ), and Terron-Almenara and Li ( 2023 ). As interpreted from these authors, most of the mentioned challenges are attributed to limitations that empirical classification systems present to capture ground behavior and utilize that input to describe the rock mass and derive rock support design. Such limitations not only affect well-known classification systems such as the Rock Mass Rating (RMR) of Bieniawski ( 1973 , 1989 ), the Q-system (Barton et al. 1974 ; NGI 2015 ), and the Geological Strength Index (GSI) of Hoek ( 1994 ), but also the mentioned national design guidelines used in Norway (NPRA 2024 ).

In response to these limitations, there has also been research showing the beneficial effect of involving more methodologies and more elaborated work to derive adequate support designs under complex rock mass conditions. For example, in Bieniawski ( 1997 ), Hudson and Harrison ( 1997 ), Russo et al. ( 1998 ), Riedmüller and Schubert ( 1999 ), Palmstrom and Stille ( 2006 ), Russo and Grasso ( 2007 ), Hoek ( 2007 ), Stille and Palmstrom ( 2008 ) and more specifically for Scandinavian shallow, hard rock tunneling conditions, in Töyrä ( 2004 ). In general, the authors recommend the study of the ground behavior and the integration of different methodologies such as empirical approaches, advanced numerical analyses assisted by deformation monitoring, and analytical approaches.

Despite the wide variety of available methodologies for rock support design, there is a general lack of concrete and unified procedures enabling an integration of these methodologies to ultimately derive optimal support designs in low rock overburden conditions. In that sense, a hybrid method as proposed in Terron-Almenara et al. ( 2023 ) was developed on the basis of a retrospective stability analysis of more than one hundred hard rock tunnel cases, including also low overburden tunnels. The goal of that procedure was to provide practical design guidelines to assess adequate support designs on the basis of an elaborated study performed from the combination of different design approaches including rock mass classification and the study of ground behavior. Since its development, however, there has not been any practical application of this procedure in low overburden tunnels.

In this article, the rock mass conditions and the support design of the Hestnes tunnel are studied to derive the limitations of the current empirical methodology used in Norway (NPRA 2023 , 2024 ) for low rock overburden tunnels. In this regard, two main objectives were outlined for this study:

Investigate the rock mechanical conditions that control tunnel stability and the beneficial effect of rock arching in low rock overburden tunnels.

Develop recommendations for rock mass classification and support design that can contribute to the assessment of adequate and more optimal support designs in low overburden tunnels.

To fulfill these objectives, the performance of the current empirical methodology was numerically studied in the hard rock and low overburden conditions of the Hestnes tunnel in two tunnel sections, 93 + 999 and 94 + 006. A detailed characterization of the ground conditions involving laboratory testing, field work, deformation monitoring and stress measurements formed the basis of a comprehensive package of numerical calculations in RS2 (Rocscience 2022 ). As a result, new design recommendations using an integrated approach that combines classification methodologies with numerical analyses and a comprehensive study of the ground properties and behavior were proposed for low overburden tunneling conditions in hard rock masses of quality Q < 1.

2 The Hestnes Railway Tunnel

The construction of the new Hestnes railway tunnel between Kleverud and Espa (Fig. 2 ) is part of a major railway upgrade project undertaken by the Norwegian Railway Administration (Bane NOR) between the cities of Eidsvoll and Hamar in Southern Norway. The cross section of the tunnel is 125 m 2 , about 14 m wide, and D-shaped. The excavation has been done with conventional drill-and-blast methods along the 3 km long tunnel. Rock mass assessments, and design of permanent rock support have been based on empirical rock mass classification systems, such as the Q-system and its simplified version published by NPRA ( 2023 , 2024 ). The design of the permanent tunnel support is based on combinations of rock bolts, fiber reinforced sprayed concrete (Sfr), and Ribs of Reinforced Sprayed concrete (RRS).

The new Hestnes railway tunnel. a Location of the tunnel project in Norway, b Alignment of Hestnes tunnel (line in green color), alignment of existing E6– motorway (line in blue color), location of in-situ stress measurement location (orange dot), and rosette plot of principal orientations of geological structures, and c Geological profile of the study area at the Kleverud site in the Southernmost part of the tunnel project

There are two main geological units in the area of the tunnel project. One which comprises granitic to augen gneiss rocks; and a second that consists of amphibolite rocks (NGU 2022 ). According to Slagstad et al. ( 2020 ), both units belong to the tectonic Sveco-Norwegian belt, of about 950–1150 Ma of age, which tectonically represent the Southwestern margin of Fennoscandia. Mapping of geological structures inside the tunnel has revealed three main joint orientations as illustrated in the rosette plot in Fig. 2 b. These are mostly oriented in the NNW-SSE, NNE–SSW and E–W directions, which match with the orientation of the geological lineaments interpreted from depressions on the topography of the area. The E-W orientation represents the strike of the foliation in the granitic gneiss.

The study area is located at the Southernmost part of the tunnel, at the Kleverud portal area and covers approximately the first 100 m of tunnel from the South tunnel entrance at 93 + 930 (Fig. 1 ) and up to 94 + 055 as shown in Fig. 2 c. At this tunnel part, the main lithology is granitic gneiss with intercalated bands of hard amphibolites disposed subhorizontally. In this tunnel stretch, some subvertical and thin zones and seams were crossed, but without creating any stability issue during tunnel excavation.

Nevertheless, the main rock mechanical characteristic that describes best the study area at the Kleverud side was the rather low overburden tunneling conditions (0.5–1 D) over a relatively long tunnel stretch in competent and hard rock (Figs. 1 and 2 c). Another relevant characteristic of the study area was the conservative approach employed in rock mass classification and support design during construction for the tunnel stretch 93 + 930–94 + 025. In that sense, assessments on rock mass classes and support design performed in pre-construction stages had anticipated the use of load-bearing RRS-arches all the way through the mentioned tunnel stretch due to the low overburden conditions. During construction, however, such design was not updated with the actual rock mass conditions nor with the observed stability and ground behavior. This motivated the systematic installation of RRS-support over nearly 95 m of tunnel regardless the hard and compact character of the rock mass, with the associated need to “adjust” mapped Q-parameters as discussed in Sect. 4.1 .

3 Current use Of Rock Mass Classification for Support Design in Tunnels With Low Rock Overburden in Norway

In Norway, the empirical approach has traditionally formed the basis for rock support design in hard rock tunnels. Typically, with the involvement of rock mass classification systems together with observation and engineering experience. The Q-system of Barton et al. ( 1974 ) and the subsequent updates of Grimstad and Barton ( 1993 ), Barton ( 2002 ), Grimstad et al. ( 2002 ), Barton and Grimstad ( 2014 ), and NGI ( 2015 ) have been used for the purposes of rock mass description/classification and rock support design. Rock mass classifications and rock support design in Scandinavian hard rock tunneling are similarly based on the rock mechanical principle of utilizing the rock mass as a bearing structure by conserving or improving the self-bearing capacity of the jointed rock. This is normally achieved with the installation of rock bolts and fiber reinforced shotcrete (Sfr). In weak and incompetent rock masses, load-bearing support in the form of RRS-arches is normally added to stabilize the rock mass (NFF 2008 ).

The design of tunnel rock support in Norway is additionally subject to comply with the national design guidelines published by NPRA in Pedersen et al. ( 2010 ) and its subsequent revisions (NPRA 2016 , 2020 , 2024 ). These guidelines are similarly used by the Norwegian Railway Administration (Bane Nor) to derive permanent rock support in Norwegian railway tunnels (NGI 2019 ; Bane Nor 2024 ). Such guidelines are based on a simplified version of the Q-system with a reduced number of rock mass classes as shown in Table 1 . The latter involves a higher level of conservativeness when compared to the Q-system (NGI 2015 ) due to the reduced design flexibility of prescribed support in tables (Terron-Almenara 2022 ).

The only rock engineering recommendations for low overburden tunnelling in Norway are in connection to rock support procedures at tunnel portals with low overburden (NFF 2008 ; NPRA 2023 ). As such, a frequent support design solution has consisted of systematic RRS-arches combined with spiling bolts in the first tunnel meters where the rock mass is often more distressed and weathered. Further in the tunnel and outside the influence of the portal, the rock mass is empirically evaluated, and leaner combinations of shotcrete-bolt support are designed depending on the rock mass conditions.

From a rock mechanical perspective, low rock overburden tunnels are subject to gravitative-induced stability failures, in which stability becomes greatly controlled by the ability of the rock mass to arch. As illustrated in Fig. 3 , both rock arching and the failure mechanics of jointed rock roofs are governed by a complex interplay of rock mechanical parameters such as the joint orientation relative to the tunnel, the shear strength of joints, rock competence, the stress confinement, and the characteristics of the reinforcement. The latter represents a typical rock engineering problem defined by the failure mechanics of jointed rock tunnel roofs. This has been traditionally addressed by the Voussoir analogue (Evans 1941 ; Sterling 1980 ; Lang and Bischoff 1982 ; Diederichs and Kaiser 1999 ; Abousleiman et al. 2021 ; Sofianos 1996 ). The essential principle is that jointed, discontinuous rock masses can develop a bearing resistance from the generation of a compression arch (or rock arching ) in which the vertical ground load is transferred in the form of compressive stresses to the joints separating the distinct hard rock blocks around the tunnel. This enhances the shear resistance of joints and block interlocking within the arch, improving therefore tunnel stability (Stille et al. 2004 ). With the installation of rock reinforcement with rock bolts, shotcrete, movements in the rock blocks are limited. Hence, the arching effect is conserved or even improved. A similar effect is provided by bolt spiling as noted in Trinh et al. ( 2007 ) and Oke et al. ( 2014 ).

Schematic cross section of a low– overburden tunnel (< 1 D) in hard rock illustrating the interaction of rock reinforcement and rock support in an isotropically jointed rock mass. Rock bolts around the excavation and spiling above the crown hold hard rock blocks together and contribute to rock arching (grey color) to restrain gravitative failure and ground loading from potentially unstable rock (dark brown color). Tunnel span ca. 10 m

To some extent, the mobilization of strength through shear at joints and rock arching are captured in empirical classifications such as the Q-system. For example, with the detailed study of the Q-parameters Jn, Jr or even Ja, or by adjusting the Stress Reduction Factor (SRF) up to 5 for “low-overburden conditions” as recommended in NGI ( 2015 ). However, the current practice in Norway has had a tendency of utilizing conservative solutions as observed in some recent tunnel projects. For example, with the utilization of load-bearing supports such as RRS-arches even when encountering hard, competent, and self-bearing rock masses (i.e., Hestnes tunnel). In other words, the assessment of rock support design has principally run independent of the beneficial (and known) stabilizing effect of rock arching, resulting in conservative designs.

4 Ground Conditions at the Study Locations 93 + 999 and 94 + 006

4.1 rock mass mapping.

Mapping of the rock mass and classification were performed in the tunnel part with limited rock overburden at the Kleverud side from 93 + 980 and up to chainage 94 + 055. The mapped rock masses consist of hard and competent granitic gneiss with bands of intercalated amphibolites. In general, relatively high values of RQD were obtained, which is a reflect of the relatively low degree of jointing in the rock mass (Fig. 4 ). Three joint sets with slightly rough joint surfaces and with low joint alteration were the most typical conditions observed. Dry conditions to small drippings were observed along the mapped tunnel sections, suggesting a value around 1 for the Jw-parameter.

Statistic distribution of logged Q-parameters RQD, Jn, Jr and Ja in the Hestnes tunnel section between 93 + 980 and 94 + 055

As mentioned in Sect. 2 , the assessment of rock mass conditions before and during construction was conservative. During construction, the SRF-value was set at an artificially high value to obtain a fit between mapped rock mass conditions and the pre-construction design based on RRS arches. This is illustrated in Fig. 5 , showing the adjusted SRF-values done during construction. In this way, the pre-construction design with RRS-support would conform to the mapped rock mass conditions during construction. As noted, the adjusted SRF-values are the result of a pre-conceived aim for lowering Q-values below 0.2, which is the threshold-value for Support class IVb (NPRA 2024 ) and the installation of load-bearing support in the form of Single reinforced (Si) RRS-arches. In Fig. 5 , a separate SRF assessment done by the authors of this article is also illustrated, by applying the mapping recommendations in the Q-system as in NGI ( 2015 ). As such, a SRF value of 5 is used in our study since it defines a depth of the tunnel crown below the surface that is below 1 D.

Adjusted SRF and Q values during construction for the portion of the Hestnes tunnel from 93 + 980 to 94 + 055 (curves in black color), compared to an assessment of SRF and Q-values done by the authors of this paper following the classification guidelines given in NGI ( 2015 ) (curves in orange color)

The rock mass conditions at the two study tunnel sections 93 + 999 and 94 + 006 are shown in Figs. 6 and 7 , respectively. A summary of the assessed component values in the Q-system is presented in Table 2 . The rock mass at both locations presents a low degree of jointing, mostly with unweathered joint surfaces and a compact and hard character as so derived from the estimation of the Q base -values before the application of the J w and SRF-reduction parameters. When applying J w and SRF for the determination of Q -values and support classes, Q -values of 0.83 and 2.1 are obtained for the tunnel chainages 93 + 999 and 94 + 006, respectively. In addition, the rock mass structure was seen to be partly influenced by the presence of 2–3 m thick and subhorizontal rock beds. As illustrated in Figs. 6 and 7 , intercalations of amphibolite rocks (of brownish tonalities) were usually placed in between the mentioned bedding.

Rock mass conditions at chainage 93 + 999 in Kleverud area, with 6.1 m of rock overburden a Photo of tunnel face showing rock mass conditions (Courtesy of Veidekke ASA), b Mapping of main joint sets and lithology at the face (green color: amphibolite; purple color: granitic gneiss). Rock mass quality Q 0.83 and Q base 4.15. Mapped GSI 60

Rock mass conditions at chainage 94 + 006 in Kleverud area, with 7.2 m of rock overburden a Photo of tunnel face showing rock mass conditions (Courtesy of Veidekke ASA), b Mapping of main joint sets and lithology at the face (green color: amphibolite; purple color: granitic gneiss). Rock mass quality Q 2.1 and Q base 15. Mapped GSI 65

4.2 Joint and Rock Properties

Three main joint sets were identified at the two study locations. Measurements and testing were performed for the determination of the orientation and shear strength parameters of the joints. Orientation was measured in the form of dip and dip direction with compass, whilst roughness and strength characteristics were assessed with the Joint Roughness Coefficient (JRC) and the Joint Compressive Strength (JCS), respectively. Tilt testing to determine the basic friction angle of joints \(({\phi }_{\text{b}})\) was also performed. The results were then used, together with the empirical formulation of Barton and Choubey ( 1977 ), to determine the residual friction angle of joints \(({\phi }_{\text{r}})\) . Accordingly, the results showed that \(({\phi }_{\text{b}})\) in the granitic gneiss was 24.4° whilst that in the amphibolite was 28.2°, which resulted in a residual friction angle \({\phi }_{\text{r}}\) of 23.2 for the granitic gneiss and 22° for the amphibolite. In addition, measurements of joint spacing ( S ) and persistence ( P ) were taken for each joint set. A summary is presented in Table 3 .

The mechanical properties of the intact rock such as the uniaxial compressive strength \({(\sigma }_{\text{ci}})\) , the Young`s modulus of intact rock \(({E}_{\text{i}})\) , and Poisson`s ratio \((\upnu )\) were estimated from laboratory testing on core samples retrieved from bore holes performed before and during construction (Bane Nor 2015 ; Rian 2023 ). The unit weight of the rock material ( γ ) was also tested, resulting in 27.3 kN/m 3 for the granitic gneiss and 29.2 kN/m 3 for the amphibolite. Material constants for the description of the peak and post-peak rock strength in the Generalized Hoek–Brown failure criterion were estimated based on the recommendations in Hoek et al. ( 2002 ) and Crowder and Bawden ( 2004 ). A summary of the properties is presented in Table 4 .

4.3 In-situ Rock Stresses

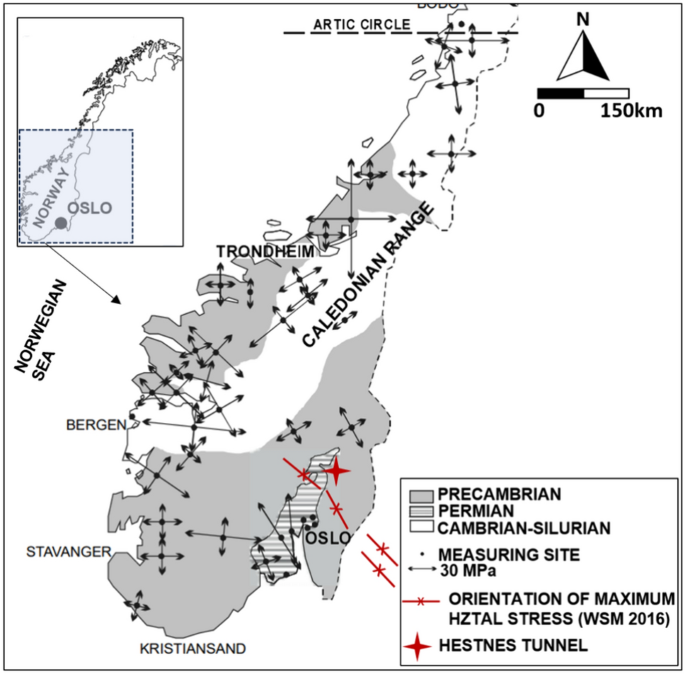

According to Stephansson and Zang ( 2012 ), the estimation of in-situ stresses for underground works at a particular site should be carried out in combination with stress measurements and the study of the broader geological and tectonic context of the region. In that sense, the research work and studies performed by authors such as Fejerskov ( 1996 ), Myrvang ( 1996 ), Fejerskov and Lindholm ( 2000 ), Simonsen ( 2018 ), and Heidbach et al. ( 2018 ) describe NW–SE trends for the orientation of the maximum horizontal stress \(({\sigma }_{\text{H}})\) in the region where the project is located (Fig. 8 ).

Orientation and relative magnitude of horizontal stresses in Southern Norway in relation to the Hestnes tunnel location. Modified after Myrvang ( 2002 ) and the World Stress Map (WSM) of Heidbach et al. ( 2018 )

Myrvang ( 2002 ), also mentions that the level of compressional stresses of tectonic origin in Norway are in close connection to the geological and tectonic contexts. As such, Norwegian bedrock is typically subdivided into three tectonic provinces as shown in Fig. 8 . One of Precambrian age which usually presents relatively large horizontal stresses and crystalline rocks like gneiss and granites. Another of Cambrian-Silurian age representing fractured metasediments. And the third one formed by igneous rocks of Permian age in the area of Oslo. The Hestnes tunnel is located in the Sveco-Norwegian orogeny province, which is part of the Precambrian belt. As indicated by the relative size of the stress tensors plotted in the area of the project (Fig. 8 ), relatively large horizontal stresses oriented NW–SE dominate in Precambrian rocks in the region where the project is located.

Following Amadei ( 1996 ), Amadei and Stephansson ( 1997 ), Zang and Stephansson ( 2010 ), and Basnet and Panthi ( 2019 ), both the magnitude and the orientation of horizontal stresses can be influenced by the rock mass structure, the geology, the degree of jointing, and the topography. Considering that the main direction of the regional lineaments in the area of the project are oriented NNW–SSE, NNE–SSW and E–W directions (Fig. 2 b), some degree of rotation may be expected in \({\sigma }_{\text{H}}\) to likely align from its tectonic NW–SE orientation to that of the more pervasive NNW-SSE structures.

In addition to the above considerations about the geological and tectonic context of the region, measurement of the in-situ stresses was also performed in the tunnel project during construction. The test location was placed at the intersection of one of the access tunnels with the Hestnes tunnel at chainage 94 + 850, with a rock overburden of ca. 70 m, and about 1 km distance to the tunnel sections under study in this article. The measurements of in-situ rock stresses were carried out in two different holes disposed horizontally in the tunnel wall at 94 + 850, ca. 1.5 m long each, oriented NE–SW, and placed about 5 m distance from each other. The stress measurements were done by SINTEF (SINTEF 2023 ), utilizing the doorstopper method (Leeman 1964 , 1971 ; Myrvang 1976 ). The method is based on the determination of the stress state from boreholes where overcoring of rock at the bottom of the hole produces a strain relief that can be registered by a strain cell glued to the bottom rock and then correlated to stress by knowing the elastic properties of the rock (Amadei and Stephansson 1997 ). To find the stress state, the method similarly assumes that at least one of the principal stresses is aligned with one of the two boreholes and that the rock is homogeneous, continuous, isotropic and presents elastic behavior (Sjöberg et al. 2003 ).

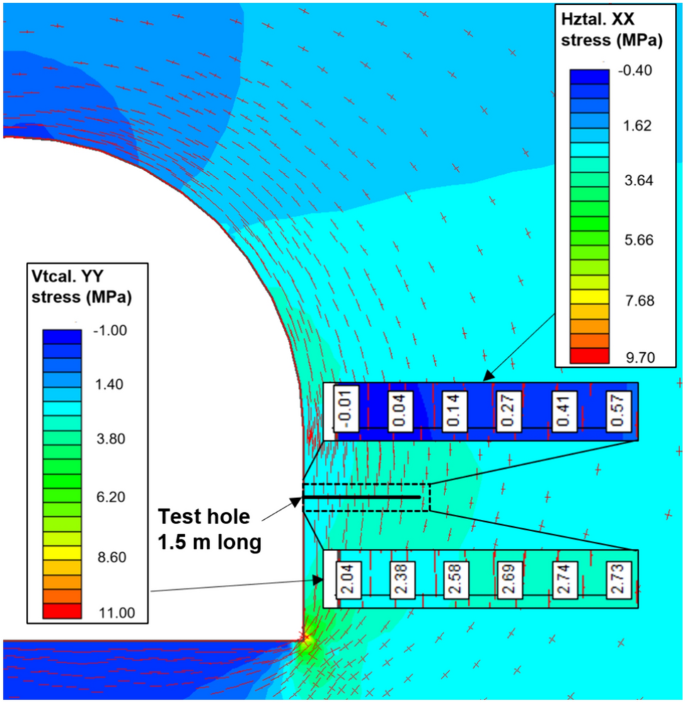

The measurement results from doorstopper testing at 94 + 850 are presented in Table 5 . It is emphasized that the hole length of the testing bore holes was too short. Consequently, leading to measurements performed in disturbed rock mass behind the tunnel wall. This affects the magnitude of the measurements as observed from the low vertical stresses obtained in the test borehole 2, or by the tension stresses (negative values) measured in the horizontal direction (Table 5 ). To enable interpretation of a reliable stress state at the test-location 94 + 850, back-calculation analyses and calibration of the measured in-situ stresses were needed. Such back-calculation was carried out on the basis of a vertical, gravitative stress of 1.9 MPa that corresponds to a rock overburden of 70 m at which stress measurements at 94 + 850 were conducted. In an iterative process performed in RS2, different combinations of horizontal to vertical stress ratios ( \({k}_{H}\) and \({k}_{h})\) were tried.

The numerical calibration is presented in Fig. 9 . It presents the calculated in-plane horizontal stress and the vertical stresses induced by the excavation in a simulated testing-hole of same length and location as that of the stress measurements performed at 94 + 850 with 70 m rock overburden. As observed, the best correlation between the measured and calculated stresses was achieved with borehole 2 (Table 5 ), with rather low (almost negative) values for horizontal stress, and values of vertical stress in the same order of magnitude. On the basis of the back-calculated stresses in RS2 (Fig. 9 ), the tectonic context, and the 70 m of rock overburden, the magnitude and direction of the maximum horizontal stress ( \({\sigma }_{\text{H}}\) ), the minimum horizontal stress ( \({\sigma }_{\text{h}}\) ), and the vertical stress ( \({\sigma }_{\text{v}}\) ) representing the stress state at the test location were interpreted. The interpreted stress state is presented in Table 6 and yields an approximate ratio \({k}_{\text{H}}\) ~3 for location 94 + 850. This stress situation correlates with observations done by Holter ( 2014 ) and Rian ( 2023 ) for the assessment of in-situ stresses at similar depths in the Ulvin tunnel, placed about 10 km south from the Hestnes tunnel.

RS2 back– calculation of in-plane horizontal stress, and vertical stress at the doorstopper test location (chainage 94 + 850, tunnel depth 70 m). Note background of the model shows the plot of vertical stresses

To utilize the back-calculated in-situ stress state obtained at the test-location (94 + 850) for the study of tunnel stability in the low-rock overburden area of Kleverud, however, further assessments were required. Among other reasons, because of the very low rock overburden of the two tunnel cases under study at Kleverud (6.1–7.2 m) if compared to that of the stress-measurement location at 94 + 850 (70 m). An additional numerical study was therefore conducted by setting a large-scale rock mechanical model to simulate the influence of the topography and the geology on the stress level at Kleverud (Fig. 10 ). Such model is oriented approximately NW–SE, which is the direction of the tunnel plane at the study location (Kleverud). In the rock mechanical model, the test-location in the access tunnel, the low-rock cover tunnel at Kleverud, the interpreted fault zones, the geology conditions, and a detailed topography including the bottom of the Mjøsa lake were simulated (Fig. 10 a). In such model, the vertical stress ( \({\sigma }_{\text{v}}\) ) is assumed to be gravitational, whilst the major and minor horizontal stresses, ( \({\sigma }_{\text{H}}\) ) and ( \({\sigma }_{\text{h}}\) ) respectively, are controlled by the respective \({k}_{H}\) and \({k}_{h}\) ratios obtained from the back-calculations presented in Fig. 9 and Table 6 .

Numerical calculations in RS2 to derive in-plane in-situ stresses at Kleverud area, based on the back– calculated in-situ stress state at the test– location of the Access tunnel. a Large– scale rock mechanical model to simulate the influence of topography and geology, b Plot of \({\sigma }_{\text{yy}}\) at the Kleverud area, c Plot of \({\sigma }_{\text{xx}}\) at the Kleverud area. Note that rock mass in this model is simulated as elastic and isotropic, with \({E}_{\text{rm}}\) = 32 GPa, whilst fault zones are simulated as explicit geological structures with normal stiffness \({K}_{\text{n }}\) =2 GPa/m and a shear stiffness \({K}_{\text{s}}\) = 0.76 GPa/m, being both \({K}_{\text{n}}\) and \({K}_{\text{s}}\) determined as suggested in Basnet and Panthi ( 2019 )

When observing the results for principal stresses (sigma 1) in Fig. 10 a, the important effect of the topography and geology in the distribution and magnitude of stresses over the entire model is noted. To analyze the stress state at the study area (Kleverud), additional analyses were conducted in RS2, from which the in-plane vertical stress \({\sigma }_{\text{yy}}\) and the in-plane horizontal stress \({\sigma }_{\text{xx}}\) were derived in the respective Fig. 10 b, c. Such analysis considered the angle (75°) formed between the tunnel alignment with respect to the direction of \({\sigma }_{\text{H}}\) , to resolve the magnitude and orientation of the in-plane stresses and of the out-of-plane horizontal stress \(({\sigma }_{\text{zz}})\) . As observed, the plots for \({\sigma }_{\text{yy}}\) and \({\sigma }_{\text{xx}}\) in Figs. 10 b, c contain vertical query lines in which the value of the calculated stress before excavation is plotted at regular intervals from the surface to a depth of ca. 26 m. To allow for a better visualization of the results of \({\sigma }_{\text{yy}}\) and \({\sigma }_{\text{xx}}\) in relation to the tunnel, the calculated stresses from Fig. 10 b, c were additionally plotted in a graph (Fig. 11 ).

Plot of back– calculated total stresses before excavation, considering the influence of topography and geology at the study location (Kleverud)

As observed in Fig. 11 , approximately the first 10 m of rock beneath surface are significantly influenced by the very low rock overburden. In that portion of the rock mass, a nearly isotropic stress condition defined by \({k}_{H}\) ~1 is interpreted at the center roof of the tunnel, whilst relatively low horizontal stresses ( \({k}_{H}\) < 1) characterize the rest of the rock mass from the tunnel roof up to the surface. The latter would indicate distressed rock above the tunnel roof and abutments in both study cases, 93 + 999 and 94 + 008, characterized by very low in-plane horizontal stresses \({\sigma }_{\text{xx}}\) , if compared to the vertical stresses \({\sigma }_{\text{yy}}\) . As it is also observed in the stress trajectories in Fig. 10 b, c, the influence of the topography on the horizontal stress \({\sigma }_{\text{xx}}\) declines with depth, reaching a stress condition defined by \({k}_{\text{H}}\) ~ 2 at the invert level in Fig. 11 . The horizontal confinement in the rock mass becomes, therefore, more independent of the rock overburden and topography from approximately 10 m below ground surface. For numerical modelling of tunnel stability purposes (Sect. 7 ), the results in Figs. 10 b, c and 11 suggest that the most representative stress state for the low-rock overburden tunnel cases in Kleverud is that of a partially distressed rock mass, i.e., \({k}_{\text{H}}\) ~ 0.5. Accordingly, a stress state representing such stress situation, to be used in the RS2 models in Sect. 7 , was derived (Table 7 ).

4.4 Deformation Monitoring

Deformation measurements were performed during the tunnel excavation. For that purpose, total stations and optical reflectors attached to the supported tunnel contour were utilized. With the total stations, 3D measurements of the targets were carried out to estimate deformations in the form of changes in the N–S, E–W, and elevation coordinates over time. A monitoring section was placed about 5 m inside the tunnel (ca. 93 + 935) and the vertical movements were registered in three monitoring points attached to the tunnel crown as shown in Fig. 12 .

Vertical displacements measured at tunnel chainage 93 + 935 in November 2022

As observed, the vertical movements were of very little magnitude, maximum 1 mm during construction. It should be noted, however, that the magnitude of the registered horizontal movement in the E–W direction was slightly higher, up to 4 mm in the monitoring point “2” at the center crown. Such movement may be interpreted as a block rotation or possibly as the lateral consequence of joint dilation that results from the vertical movement in the rock blocks. For this reason, the vertical movements were utilized for the back-calculations in this study. It should be noted that measurements of the deformations were taken some meters behind the face.

5 Analysis Methodology

In general, the analysis methodology has comprised a combination of detailed site investigations, empirical methods, numerical modelling, and analytical calculations. Such methodology has allowed the study of the limitations of current rock mass classification systems used in Norway for support design in tunnels with low rock overburden. Two tunnel sections of the Hestnes tunnel at the Kleverud area, 93 + 999 and 94 + 006, were utilized as case studies for the investigations and analyses presented in this article.

The study is principally based on the analysis of the ground behavior and support performance. A central part of the analyses is, therefore, represented by numerical analyses performed with geotechnical software for rock mechanical simulations. Two numerical models were then analyzed for each tunnel section. The first model in each section simulates the ground behavior and support loading when applying a conservative approach as that currently practiced in Norway for low rock overburden tunnels following adjustments of SRF-values as shown in Fig. 5 . The second model in each section contains identical rock mass conditions, but considers a tunnel support design performed by following the recommendations for rock mass classification in the Q-system (NGI 2015 ) and verified with numerical calculations. As shown in Table 8 , this results in a total of four numerical models. As such, the respective A1 and A2 models at 93 + 999 represent the current (and conservative) classification practice, and the empirical NGI-based (and numerically verified) designs. And so does for B1 and B2 models at tunnel section 94 + 006.

The methodology followed in the study has considered several analyses. These analyses are similarly of different nature and subdivided into steps through a procedure or methodology as illustrated in Fig. 13 . Such illustration is followed by a detailed description of the different analysis steps along the analysis.

Step 1. A rock mechanical model is assembled in the first step. Such model represents the initial rock mass conditions at the location of the study section 93 + 999 and 94 + 006, to be simulated in the numerical calculations. The rock mechanical models are based on registrations of rock mechanical data, face mapping, rock mass classification, site-investigations, and laboratory testing as described in Sect. 4 . Based on this, a first set of representative rock mechanical properties of the rock and joints are modelled with the geotechnical software RS2 v.11 (Rocscience 2022 ).

Step 2. Calibration of the models is a necessary process in any rock engineering design involving stability analyses of rock and support (Sakurai 2017 ). The calibration was done through an iterative process in which back-calculations are performed with different sets of input rock mass properties (taken from Sect. 4 ) with the aim of comparing the observed (measured) displacements and the calculated results (outputs). See Sect. 6 . Such comparison is used to define a representative set of rock mass properties describing the “calibrated” model. It should be noted, however, that such back-calculation process normally involves some limitations and assumptions (Walton and Sinha 2022 ) that need to be considered:

a) It is assumed that the RS2 software and the utilized constitutive laws for the rock material and joints (described in Sect. 6 ) can capture the behavior of the studied cases, i.e., tunnel excavation in hard and jointed rock and subject to low rock overburden.

b) Both the method and the deformation measurements carried out with total station and reflectors are assumed reliable. In addition, there are no evidence of time-dependent deformations in the period that has covered the construction of the tunnel, indicating that the rock mass is stable.

c) The first deformation monitoring reading was taken about 2 m behind the face. Deformations occurring ahead of the face and before the first reading are, therefore, not registered. It should be then emphasized that RS2 calculates total displacements. To ensure comparability between calculated deformations to actual deformations measured in the tunnel and enable model calibration, deformations occurring ahead and behind the face were calculated in RS2 (See Sect. 6 ).

d) Different sets or combinations of input parameters may yield a similar response (output). To minimize any possible reliability issue related to such non-uniqueness in the back-calculation and calibration process, the modelling was constrained as much as possible with the utilization of all available rock mechanical information as suggested in Sjöberg ( 2020 ).

e) The reinforcement effect of bolt spiling and pre-excavation grouting of the rock mass was not included. Among other reasons, to allow a study in which the reinforcement effect of shotcrete and bolts on ground behavior is isolated from the more complex reinforcement mechanics of spiling bolts (Oke et al. 2014 ) and grouting.

f) As noted by Elmo and Stead ( 2021 ) and Walton and Sinha ( 2022 ), the combination of rock mass characterization with numerical calibration can help to reduce uncertainty and improve model reliability. However, the same authors also mention that uncertainty is impossible to eliminate, due to the inherent limitations of the methods employed in rock engineering. To minimize the effect of reliability and uncertainty issues in the study, the authors have combined and integrated different calculation tools and approaches in the analyses as shown in the procedure presented in Fig. 13 . The aim was to utilize the advantages of each of the involved analysis methodologies to cover limitations that design tools may present for this type of poor ground conditions, as suggested in Spross et al. ( 2020 ) and Terron-Almenara et al. ( 2023 ).

Step 3. The calibrated models are solved to reach equilibrium and the results evaluated in the form of ground behavior and support loading. Ground behavior was assessed in terms of rock displacements and stresses whilst performance of the support design was studied with support capacity diagrams produced in RS2. Factors of Safety (FS) against structural failure of the reinforced shotcrete support (RRS) can be then derived for the different shotcrete support systems. Since typical failure of shotcrete in hard and jointed rock mases subject to low stresses and gravitative-driven behavior is primarily related to shear and bending loading (Kaiser and Tannant 1997 , 2001 ), the study focuses on these types of failure. Accordingly, FS has been derived from the calculation of the acting bending moments ( M ) and shear forces ( V ) against the respective moments of resistance \(({M}_{\text{R}})\) and the shear resistance \(({V}_{\text{R}})\) of the support as defined by Eqs. 1 and 2 .

where FS c-bending is the factor of safety of the sprayed concrete to fail in bending, ( M RC ) is the moment of resistance of the shotcrete support system, FS c-shear the factor of safety of the sprayed concrete to fail in shear, and ( V RC ) the shear resistance of the shotcrete support.

General analysis methodology for the study of ground behavior and support performance when using rock mass classifications for rock support design in low rock overburden tunnels

For models A2 and B2, however, the rock support design does not involve steel reinforced shotcrete support (RRS) and RS2 cannot produce support capacity diagrams. The moment resistance or capacity ( M RC ) and the shear capacity of the shotcrete support ( V RC ) were then determined following analytical formulation of shotcrete support capacity as recommended in Holmgren ( 1992 ) and Bernard ( 2008 ) in Eqs. 3 and 4 , respectively:

where \(({\sigma }_{\text{fl}})\) is the flexural strength of the fiber reinforced sprayed concrete, \((t)\) is the thickness of the sprayed concrete layer, \((l)\) the critical perimeter, and \(({\sigma }_{\text{sh}})\) the shear strength of the sprayed concrete.

According to authors like Barrett and McCreath ( 1995 ), Malmgren ( 2005 ), and Bjureland et al. ( 2020 ), solutions as that presented in Eq. 3 provide good estimates of moment resistance of shotcrete support. However, the same authors also emphasize that these types of solutions are based on simply supported and straight beam models with even thickness and no adhesion to the ground. This could yield some conservativism in the results when used for rock tunnels. One of the reasons is that the beneficial effect of the adhesion rock/shotcrete to mobilize strength and take up ground loads is neglected. The second reason is that curved shotcrete support members -for example in tunnel roof can build up additional moment resistance from their curvature, as opposed to flat shotcrete plate models that are considered in the analytical solution of Eq. 3 .

Loading and performance of rock bolts were also studied from the FS results and by applying analytical calculations of limit state for axial failure of fully grouted rebar bolts. As such, the limit state at axial failure of the bolt \({(FS}_{\text{b}})\) is defined by Eqs. 5 and 6 .

where \({(T}_{\text{b}})\) is the tensile capacity of the bolt, \({(Q}_{\text{b}})\) the axial load acting on the bolt, \(({A}_{\text{b}})\) is the cross sectional area of the bolt and \(({f}_{\text{b}})\) is the yield strength of the steel.

Step 4. The study of the results from step 3 is done to find possible improvements in the current practice used for rock mass classification and support design in tunnels with low rock overburden. Since each of the pair of models A1-A2 and B1-B2 contains both a conservative rock support design and an optimized design, the comparison of FS and ground behavior in each of the pairs gives, therefore, a measure of the conservativism used in the current practice. Hence, it gives indications to derive improvements in the current classification and design practices for tunnels in low rock overburden conditions.

6 Set up of the Numerical Models

The numerical calculations were conducted with the geotechnical software RS2 (Rocscience 2022 ), a two-dimensional numerical program based on the Finite Element Method (FEM). The software also contains an in-built feature that permits the modelling of distinct joints intersecting the rock material. This permits the simulation of hard and jointed rock masses in which the failure mechanisms are principally dominated by shear translations through existing joints and/or rotation of rock blocks.

The RS2 models have been built in plane-strain conditions. The rock material was modelled with the Generalized Hoek–Brown failure criterion (Hoek et al. 2002 ) and an elasto-plastic material function. Rock joints were modelled with the non-linear Barton-Bandis criterion (Barton and Bandis 1990 ). The modelling with such combination of material and joint constitutive laws is deemed to be representative of the studied in-situ rock mass conditions with hard and jointed rock exposed to low rock overburden.

Three joint sets were explicitly modelled in the four numerical models to replicate the actual rock mass structure. The dip angle of the modelled joint sets as registered in the field (Table 3 ) was geometrically adjusted to compensate for the existing angle between the actual strike of the joint sets and the in-plane orientation of the models. To derive deformation modulus of the rock mass \({(E}_{\text{rm}})\) , it was first necessary an estimation with empirical methods. As such, the empirical correlations and solutions proposed by Hoek and Diederichs ( 2006 ), Barton ( 2002 ), and Abousleiman et al. ( 2021 ) were utilized. For that purpose, either the mapped Q -values or an estimation of GSI were used. The obtained estimates of deformation modulus were then subject to a calibration process.

To calibrate the numerical models, different combinations of input parameters (joint properties and rock mass properties) were run in up to eight different numerical models (Fig. 14 ). Calibration was found in such model presenting a similar numerical response at both, the deformation measurements and in the numerical calculations. It should be emphasized that the plot in Fig. 14 shows the total roof displacement calculated in RS2, i.e., displacements ahead and behind the face. To enable comparison towards the measured roof displacements taken from a monitoring section that was installed about 2 m behind the face, the calculated displacements occurring before the first reading should then be not accounted. As such, assessment of the results from such calibration process resulted in that the combination of input parameters that fit best with the measured behavior in the tunnel was those of model 4 in Fig. 14 . That is, about 2 mm of total displacement was obtained in the numerical calibration, from which ca. 1 mm already occur prior to the first reading, resulting in a measured 1 mm of vertical displacement as presented in Fig. 12 . The calibrated properties of the rock joints and rock mass are summarized in Tables 9 and 10 , respectively. As observed in the plotted curve for model 4, about 50% of the total displacements have occurred before the first reading in the monitoring section.

Plot of calculated inward roof displacements as a function of the distance to the face. Note monitoring section placed 2 m behind the face

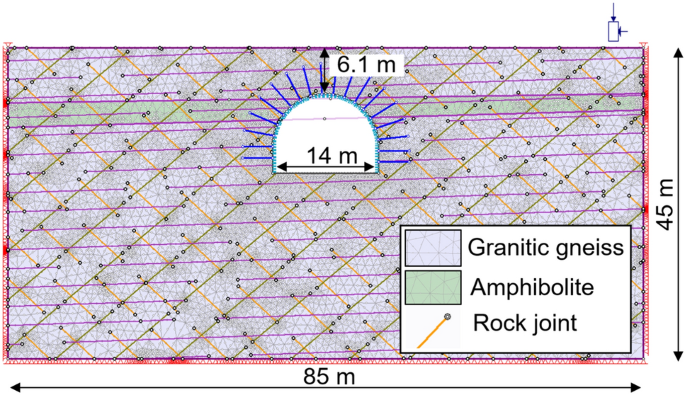

Once the properties of the rock mass were calibrated, the outer boundaries of the models were set. This was done by the creation of an external geometry or box of approximately 85 m wide and 45 m high which contains the geological model and the tunnel geometry (Fig. 15 ). To simulate the low rock overburden conditions, the tunnel was placed at a level in the model such that the resulting depth or cover above the tunnel crown represented the reality (Fig. 15 ). A graded mesh was produced automatically in RS2 and elements formed by 6-noded triangles were utilized. The external boundaries of the box except those representing the terrain surface at the top were restrained. The in-situ rock stresses were determined following the procedure explained in Sect. 4.3 , from which the stress state for both locations 93 + 999 and 94 + 008 at Kleverud was derived (Table 7 ) and included in the RS2 models.

Set up of the 2D numerical model in RS2 with restrained bottom and lateral boundaries and free top surface. Example showing A1 model, with a rock mass represented by gneiss, a subhorizontal layer of amphibolite, and three joint sets. Rock overburden is 6.1 m in this model

As explained in Sect. 5 , the four models A1, A2, B1 and B2 were calibrated before conducting the numerical analyses of ground behavior and support performance. To allow such calibration and simulate a sequential installation of the support with the excavation, the models were staged. Staging of the calculations in computational steps allowed for a determined rock mass relaxation to occur prior to rock support activation (loading) in the models. Such simulation in RS2 was done with the core replacement method (Vlachopoulos and Diederichs 2009 ; Rocscience 2022 ).

Modelling of load-bearing support such as RRS-support in RS2 was performed with the equivalent section approach. The equivalent section approach to model composite supports such as ribs or arches in geotechnical software has been used in similar studies by authors like Donovan et al. ( 1984 ), Carranza-Torres and Diederichs ( 2009 ), Chryssanthakis ( 2015 ) and Høien and Nilsen ( 2018 ), and proven satisfactorily. With such modelling approach, it is possible to derive equivalent beam sections with equivalent mechanical properties that fit in the unitary (1 m) out of plane slice thickness of RS2. This is done by weighting both the cross sectional area and the mechanical properties of the materials involved in the composite, i.e., shotcrete and steel in RRS-arches. The properties of the rock support material used in numerical models, including RRS, shotcrete and bolts, are summarized in Table 11 .

7 Analysis Results of Tunnel Stability and Support Performance

7.1 model a1 with conservative rock mass classification at 93 + 999.

Model A1 (Fig. 16 ) shows the ground response and support loading at chainage 93 + 999. The analysis is based on a simulation of the installed rock support that was designed on the basis of a conservative assessment and adjusted SRF-parameter as discussed in Sects. 4.1 and 5 . The model similarly considers the actual rock mass conditions with Q 0.83. However, with a rock support design that results from the application of the NPRA ( 2024 ) and a conservative assessment of the SRF, an “adjusted” Q-value of 0.18 and rock support class IVb were defined. Such support class consists of Sfr 150 mm, 4 m long rock bolts spaced c/c 1.5 m, and Si-RRS 30/6 spaced c/c 3 m.

RS2 model A1 with support design based on conservative assessment of SRF at 93 + 999. a Ground behavior and support loading, with plot of total displacements, bending moments on RRS– support and bolt loading, and b plot of stress contours and stress trajectories for major principal stresses (Sigma 1), c Moment– thrust diagram with FS envelopes for shotcrete in RRS– support, and d Shear– thrust diagram with FS envelopes for shotcrete in RRS– support

As observed, displacements affect mostly the center roof, but they also extend laterally to the entire crown. From the distribution and magnitude of displacements over the tunnel roof, however, it is also observed that displacements are controlled by the rock mass structure and by the intersection of discontinuities with the tunnel excavation. On the other hand, the magnitude of the calculated displacements is rather low in general (maximum 2.1 mm), which a priori denotes good stability conditions. The latter is indeed confirmed by the low rock support loading in Fig. 16 a. As such, the maximum axial bolt load \({(Q}_{\text{b}})\) reaches 84 kN in a bolt placed at the center roof and at the intersection with a bedding plane. The rest of the bolts in the crown are loaded about 40–60 kN, whilst bolts in the lower tunnel side walls present marginal to no axial loads. This would indicate that roof bolts are actually working in tension to keep blocks in place and contributing to rock mass arching. Moment loading ( M ) and shear loading ( V ) are also low, reaching -8 kNm and 25 kN, respectively.

The relatively low support loading in the A1 model can be explained with Fig. 16 b. It shows a plot of the principal stresses for the same simulation presented in Fig. 16 a. In such plot, it is notably marked the effect of arching by looking at the distribution and magnitude of compressional stresses (in greenish tonalities—Fig. 16 b) at the top part of the rock blocks and unconfined parts (bluish tonalities) at the bottom part of the rock blocks and rock beds located between the tunnel crown and the surface. Figure 16 b similarly shows an increase of stresses at the contact between rock blocks (at joints), denoting therefore the development of rock mass resistance from the mobilization of joint shear strength. Such behavior clearly indicates that the jointed rock mass, even with a relatively low rock overburden (6.1 m), is able to build up moment resistance by arching and distributing ground load from the upper midspan of the jointed voussoirs to the tunnel abutments as also illustrated by the stress trajectories in Fig. 16 b. As the rock mass is able to take a greater share of the ground load, the support is then not especially loaded. This turns into relatively high FS for the shotcrete support, as observed in the support capacity diagrams (Fig. 16 c, d) and as summarized in Sect. 7.5 .

7.2 Model A2 With Rock Mass Classification and Support Assessment According to NGI 2015 at 93 + 999

Model A2 (Fig. 17 ) shows the ground behavior and support loading for tunnel chainage 93 + 999 in which the simulated rock support corresponds to an empirical assessment using the Q-system as recommended in NGI ( 2015 ). Rock mass conditions in model A2 are kept identical as for model A1 ( Q 0.83). The simulated empirical rock support consists of Sfr 120 mm and 4 m long rock bolts spaced c/c 1.7 m.

RS2 model A2 with rock mass classification and support design based on Q-system (NGI 2015 ) at 93 + 999. a Ground behavior and support loading, with plot of total displacements, bending moments on shotcrete support and bolt loading, and b Plot of stress contours and stress trajectories for major principal stresses (Sigma 1)

The calculated displacements reach up to 5 mm in the center roof of the tunnel (Fig. 17 a). As for model A1, displacements are also distributed mostly around the entire crown, with highest displacement at the center roof and at the intersection of unfavorable rock blocks and joints with the tunnel contour. The magnitude of the displacements in A2 model is increased with respect to that of model A1 with RRS-support. However, 5 mm in A2 is also deemed a rather low magnitude and within safe margins. The latter is manifested in the results for support loading. As such, maximum bolt loading \({(Q}_{\text{b}})\) is 92 kN at a rock block in the right hand side spring line, and up to 70 kN in the center roof. The latter constitutes a slight increase with respect to model A1, but within safe margins. It is also observed that the behavior and load distribution of bolts are rather similar to that of model A1, with more bolts loaded specially towards the center roof, and loaded at the intersection of joints, indicating also that the bolts are holding the rock mass together and contributing to roof arching.

The latter is confirmed by looking at the distribution and magnitude of major principal stresses above the tunnel in between the crown and the terrain surface in Fig. 17 b. As for model A1, the distribution and magnitude of stresses in the rock blocks above and around the tunnel denote the generation of rock arching in spite of the relatively low horizontal stress confinement. Arching obviously gives an increased ability to the rock mass of model A2 to take up loads, resulting therefore in less ground loads transferred to the shotcrete support. In applying Eqs. 1 and 2 to derive the respective \({FS}_{c-bending}\) and \({FS}_{c-shear}\) of the shotcrete support, the results show that loading is within the same level as for model A1. This does not only demonstrates the adequacy of the rock reinforcement support considered after NGI ( 2015 ) for the rock mass conditions of models A1 and A2 (Q 0.83), but also confirms the conservative approach applied with adjustment of the SRF-parameter and installation of RRS-support as for model A1.

7.3 Model B1 with Conservative Rock Mass Classification at 94 + 006

Model B1 (Fig. 18 ) shows the results for ground behavior and support loading at 94 + 006. The analysis is based on a simulation of the installed rock support that was designed during construction, on the basis of a conservative assessment and adjusted SRF-parameter as discussed in Sects. 4.1 and 5 . Rock mass conditions are slightly better (Q 2.1) if compared to models A1 and A2. Rock support consists of Sfr 150 mm, 4 m long rock bolts spaced c/c 1.5 m, and Si-RRS 30/6 spaced c/c 3 m.

RS2 model B1 with support design based on conservative assessment of SRF at 94 + 006. a Ground behavior and support loading, with plot of total displacements, bending moments on RRS– support and bolt loading, and b plot of stress contours and stress trajectories for major principal stresses (Sigma 1), c moment– thrust diagram with FS envelopes for shotcrete in RRS– support, and d Shear– thrust diagram with FS envelopes for shotcrete in RRS– support

The calculated displacements are shown in Fig. 18 a. The maximum displacements are of very low magnitude (1.5 mm) and located in the tunnel roof. The latter is also manifested in the form of low support loading. If compared to model A1, fewer bolts are loaded and with less axial load in general. The maximum bolt axial load is 82 kN and is located in the center roof. As for models A1 and A2, bolt loading in model B1 is located in the crown, and with higher axial loads located at the intersection with distinct blocks.

In looking to Fig. 18 b, the general level of induced stresses in the rock blocks and rock beds located between the tunnel crown and the terrain surface is generally higher than that of models A1 and A2. From the distribution of stresses within the rock blocks and around the tunnel opening, it is similarly interpreted the formation of rock arching. Such rock arching is also confirmed by the relatively low ground load that is transferred to the shotcrete support. As such, a maximum moment loading ( M ) of -4.4 kNm and a shear loading ( V ) of 23 kN are obtained in the numerical simulations, which turns into relatively high \({FS}_{c-bending}\) and \({FS}_{c-shear}\) as observed in the support capacity diagrams (Fig. 18 c, d) and as summarized in Sect. 7.5 .

7.4 Model B2 with Rock Mass Classification and Support Assessment According to NGI ( 2015 ) at 94 + 006

Model B2 (Fig. 19 ) shows the ground behavior and support loading for tunnel chainage 94 + 006. The simulated rock support is based on the Q-system as recommended in NGI ( 2015 ). Rock mass conditions in model B2 are kept identical as for model B1, i.e., Q 2.1. The simulated empirical rock support consists of Sfr 90 mm, and 4 m long rock bolts spaced c/c 2.0 m (L3 m in walls).

RS2 model B2 with rock mass classification and support design based on Q-system (NGI 2015 ) at 94 + 006. a Ground behavior and support loading, with plot of total displacements, bending moments on shotcrete support and bolt loading, and b plot of stress contours and stress trajectories for major principal stresses (Sigma 1)

The calculated displacements reach up to 3.8 mm in the center roof of the tunnel, and their distribution also seem to be influenced by the rock mass structure (Fig. 19 a). The magnitude of the displacements in B2 model with only 90 mm of reinforced shotcrete and rock bolts is increased with respect to that of model B1 with RRS-support. However, such increase of up to 3.8 mm in model B2 is similarly deemed of a rather low magnitude. Loading of the support is relatively low, with bolt loading reaching up to FS b 80–110 kN in the crown and almost no loading in the lower tunnel sidewalls. The latter confirms the reinforcing effect of bolts in the crown by holding hard rock blocks together and contributing to arching. It is also observed that there is not a substantial difference when comparing bolt loading with the results in model A1 (poorer rock mass quality) where heavier RRS-support was installed. The latter suggests that the rock mass can arch sufficiently in both cases, A2 and B2, with the help of rock reinforcement (bolts and shotcrete), leaving, therefore, the contribution of load-bearing support almost negligible in practice.

There are also observed almost no changes in the stress situation when comparing models B1 and B2 (Figs. 18 b and 19 b, respectively). As mentioned, the rock mass arches despite of the low overburden (7.2 m) due to its stiffness, the shear strength of joints, and the contribution of the rock reinforcement to hold key rock blocks in place. Indeed, moment loading ( M ) and shear loading ( V ) of shotcrete support in model B2 remains within similar levels as for model B1 where load-bearing support was utilized, in compensation for a slight increase in bolt loading in model B2. The latter does not only denote the importance of rock bolting for rock reinforcement under low overburden tunneling conditions, but also indicates the adequacy of the support recommendation given in the Q-system (NGI 2015 ) at 94 + 006.

7.5 Summary of Results

The performance of the current empirical design method used in Norway with conservative assessments of the rock mass when encountering low rock overburden tunnels has been studied with the evaluation of ground behavior and FS of support as shown in Sects. 7.1 – 7.4 . Based on the results of support loading, it is generally observed a greater load share in the rock bolts than in the shotcrete support in the four models (Table 12 ). Such loading in the rock bolts, however, is generally not exceeding beyond half of their axial load capacity. Additionally, the calculated rock mass displacements in the four models were very lows, in the order of 1–5 mm. The latter is a clear indication that rock bolts are effectively reinforcing the rock mass above the tunnel crown and contributing to rock arching in spite of the limited rock overburden in the four models (< 1 D), as also confirmed by the numerical results for principal stresses around the excavation.

As the rock masses in the four models arch, they can take up a greater share of the ground loads. A limited ground load is then transferred onto the shotcrete support as derived from the generally low bending and shear loading in the calculations. If the latter is put in light of the heavy load-bearing support formed by Si-RRS30/6 c/c 3 m installed in both models A1 and B1 as in the reality for the respective tunnel sections 93 + 999 and 94 + 006, this yields a FS against bending of 4 and 10, respectively; and a respective FS against shear of 20 and 50. Obviously, such high and conservative FS indicates room for improvement in the current practice of rock mass classification and support assessment for low rock overburden tunnels in Norway.

In utilizing the recommendations of the Q-system (NGI 2015 ) for rock mass classification and support assessment in the respective simulations of models A2 and B2 for chainages 93 + 999 and 94 + 006, leaner support designs without load-bearing RRS-support were recommended. As such, FS against bending and shear were significantly reduced to more reasonable values in models A2 and B2 (Table 12 ) whilst not compromising stability. By following such reduction or optimization of shotcrete support in the A2 and B2 models, it was also observed a slight increment in the bolt loading for these two models, if compared to the respective A1 and B1 models. The latter, therefore, tells that by optimizing the amount of shotcrete support, a better utilization of the bolting capacity can be also achieved. Such optimization of the bolt capacity goes from a utilization of about 50% of bolt loading in A1-B1 models to about 55–65% in the A2-B2 models.

In the light of this discussion, it should be emphasized that whilst the assessment of FS for shotcrete support in models A1 and B1 is based on support capacity diagrams in RS2 (Figs. 16 c, d and 18 c, d), FS for models A2 and B2 were studied analytically as mentioned in Sec. 5 . In that sense, interpretation of FS-results should account for the higher ability and level of detail that RS2 provides to capture loading behavior (in A1 and B1 models), if compared to the analytical solutions based on limit state analyses of Eqs. 3 and 4 utilized for models A2 and B2. On the other hand, it should be similarly considered that Eqs. 3 and 4 can yield pessimistic results in general, provided that the analytical solutions are based on straight shotcrete members, as opposed to RS2 which can calculate the actual and improved moment resistance provided by the curvature of shotcrete plates covering the tunnel crown.

It was similarly observed in the four models that the presence of distinct joints intersecting the tunnel periphery had an important effect in the generation of displacements in rock blocks that resulted in either point or uneven loads of relatively low magnitudes over the crown. In that sense, it should be noted that the simulations presented in Sect. 7 are based on actual rock mass conditions, with high RQDs, relatively fresh joint surfaces, and no weakness planes or seams through which preferential failure may take place. The stable rock mass conditions and the relatively low demands of rock support obtained in the results of A2 and B2 models represent therefore such conditions. Under the situation that the rock mass was intersected by distinct discontinuities with poorer mechanical properties, a different model response should have been expected in the results.

8 Final Discussions and Recommendations

As observed in the results in Sec. 7 , and as noted by authors such as Stille et al. ( 2004 ), Li ( 2017 ) and Abousleiman et al. ( 2021 ), the horizontal confinement at the tunnel level is an important factor controlling rock arching. In principle, a situation where the horizontal stresses in a shallow tunnel are twice than the vertical stresses (i.e., \({k}_{\text{H}}\) = 2) would generally be beneficial to rock arching, block interlocking above the roof, hence roof stability, if compared to a situation with \({k}_{\text{H}}\) < 1. Such stability condition would similarly be dependent on the jointing geometry relative to the excavation, the joint conditions, and the overall strength and stiffness of the rock mass above the tunnel roof, as addressed by Töyrä ( 2004 ).

To investigate the effect that a stress situation characterized by a larger horizontal confinement (i.e., \({k}_{\text{H}}\) = 2) would have on tunnel stability with rock mass conditions comparable to those studied for model B2 at tunnel profile 94 + 006, the authors have conducted an additional study. Accordingly, numerical analyses in RS2 have been performed using the original rock mechanical model B2 defined in Sec. 6 , but considering \({k}_{\text{H}}\) = 2. The numerical results are presented in Fig. 20 , and to distinguish the results from model B2, this new model considering larger horizontal confinement ( \({k}_{\text{H}}\) = 2) was named with the superscript (*), i.e., B2*.

RS2 model B2* with rock mass classification and support design based on Q-system (NGI 2015 ) at 94 + 006 and a stress condition defined by \({k}_{H}\) = 2. Plot of total displacements, bending moments on shotcrete support and bolt loading

In comparing the numerical results of model B2 ( \({k}_{\text{H}}\) ~ 0.5) in Fig. 19 a with model B2* ( \({k}_{\text{H}}\) = 2) in Fig. 20 , both with very low rock overburden, it is observed no major differences in ground behavior and support loading in general. Compared to model B2, the deformations in model B2* follow a similar distribution around the excavation. These deformations are mostly linked to the intersection of joints with the tunnel roof, and reach a maximum of 2.4 mm, which means a very limited reduction if compared to model B2 with \({k}_{H}\) ~ 0.5. Bolt loading in model B2* is similarly concentrated at the intersection of the bolts with joints located in the tunnel roof and abutments, presenting slightly reduced bolt axial loads, around 60–80 KN in the roof and up to 52 kN in the left tunnel abutment, if compared to model B2. Regarding loading of shotcrete support, a very low loading characterized by V = 8 kN and M = -1 kNm suggests a rather marginal improvement if compared to B2 model.

Although the results from model B2* show that there is a reduction in both, the deformations and support loading with the increase of horizontal confinement, the magnitude of such improvement is very limited provided the rather competent rock mass with GSI 60–65 and Q base > 4, and the very low overburden at 94 + 006. In that sense, the shallow location of the tunnel has led to very low horizontal stresses at the tunnel level in spite of the stress situation defined by \({k}_{\text{H}}\) = 2 as that used in model B2*. In other words, tunnel stability and ground behavior in models B2 and B2* was mostly governed by the rock mass competence, the low overburden, and the ability of the rock mass to arch, and to a lesser extent, by the stress situation. In cases, however, where the rock mass may present a higher degree of jointing and poorer joint conditions, the contribution of the horizontal confinement to arching and stability would naturally turn more evident and of more relevance.

Because of the relatively low magnitude of the induced stresses after excavation and the hard, competent rock mass conditions, failure of the rock in the form of flexure or crushing would be generally not expected above the roof of the tunnel. Small areas in the corners or on the surfaces of the rock blocks where stresses are normally mobilized and concentrated may exhibit some cracking, however, without jeopardizing rock mass interlocking or stability.

8.1 Validity of Results

The presented study is based on numerical analyses performed in RS2 where displacements and stresses are studied for the assessment of the ground behavior, and support loading (and FS) as a measure of the support performance. In the two study sections, the ground conditions are characterized by a hard and jointed rock mass that is subject to very low rock overburden (< 1 D) where stability is principally controlled by the geometrical/mechanical properties of joints, the characteristics of the reinforcement and the presence of horizontal confinement. This places a significant importance in the modelling of joints. Although it is known that the finite element method as that used in the RS2 software presents limitations to simulate large displacements at joints, reasonable results reflecting the measured behavior were obtained. This could be attributed to the modelled explicit joint network combined with the non-linear Barton-Bandis joint constitutive model (Barton and Bandis 1990 ).

The Generalized Hoek–Brown failure criterion (Hoek et al. 2002 ) and the elasto-plastic material function utilized in the models were similarly observed to yield results that were consistent with the measured behavior. As such, the involvement of comprehensive studies of rock and rock joint conditions from site investigations and detailed assessments of Q-parameters have derived into representative rock mechanical models able to capture both the failure mechanisms and the important stabilizing effect of rock arching. Obviously, assumptions and simplifications that are needed in numerical modelling (Sect. 5 ) can limit the validity of the results as noted in Starfield and Cundall ( 1988 ) and Walton and Sinha ( 2022 ). However, it is deemed that the detailed level of the ground characterization and the process of model calibration have contributed to a significant reduction of possible uncertainties produced by the mentioned simplifications and assumptions.

It should be also emphasized that since bolt spiling in the tunnel crown was not modelled, the stabilizing contribution that such rock reinforcement measure may have had on the overall stability of the low overburden tunnel remains unknown. The possible outcome of the latter limitation is the potential over-representation of ground displacements, which could in principle exaggerate the estimation of support loading. Hence, the likely pessimistic assessment of FS.

It should be finally noted that the stability conditions of the Hestnes tunnel are also a consequence of the favorable rock mass conditions studied in the low rock overburden tunnel sections. In both cases, 93 + 999 and 94 + 006, no preferential weakness planes nor unfavorable joint conditions were encountered at the face. This resulted in a self-bearing rock mass upon the application of rock reinforcement. The findings in the results are, therefore, representative for these rock mechanical conditions, as explained in Sects. 4.1 and 4.2 . As a result, the derived design optimizations and the proposed recommendations of this study should be only used in other low-overburden projects as a design guideline or as a benchmark for research. Differences in the joint geometry/mechanical properties and/or the rock overburden and the rock mass condition should, therefore, require additional evaluations and adjustments over the optimizations given in this study.

8.2 Significance of the Findings

In this article, it has been shown that with the correct and non-conservative application of classification methods such as the Q-system (NGI 2015 ) in combination with more elaborated methods like numerical modelling, one can derive optimal designs of rock support in hard rock tunneling conditions with low overburden. With such non-conservative approach, leaner supports formed by shotcrete and bolts have given satisfactory stability conditions and sufficient FS against support failure as observed in the calculations of models A2 and B2. If a heavier, load-bearing support as currently practiced in Norway and as simulated in the A1 and B1 models is used whilst maintaining the same rock mass conditions, the design becomes conservative.

The results are obviously representative of the ground conditions at the two study locations, with compact and rather massive rock masses as indicated by the Q base -values ranging between 4.15 and 15. In that sense, the utilization of SRF 5 to adjust the Q base -values and capture the effect of low rock overburden has positively contributed to the determination of Q -values that were representative of the actual needs of tunnel support.

The integration of both the Q -system with numerical modelling, deformation monitoring and a comprehensive ground characterization have provided the necessary tools to derive design optimization in hard rock tunneling in low rock overburden conditions. Such approach is very much in line with a hybrid method proposed by Terron-Almenara et al. ( 2023 ) in which procedures for rock support design in low overburden tunnels are also given. As a direct consequence of the derived support optimization possibilities by utilizing the approach presented in this article, rock support consumption can also be significantly reduced without compromising tunnel stability.