- Open access

- Published: 18 October 2019

A detailed overview of xylanases: an emerging biomolecule for current and future prospective

- Nisha Bhardwaj 1 na1 ,

- Bikash Kumar 1 na1 &

- Pradeep Verma ORCID: orcid.org/0000-0003-2266-9437 1

Bioresources and Bioprocessing volume 6 , Article number: 40 ( 2019 ) Cite this article

46k Accesses

247 Citations

Metrics details

Xylan is the second most abundant naturally occurring renewable polysaccharide available on earth. It is a complex heteropolysaccharide consisting of different monosaccharides such as l -arabinose, d -galactose, d -mannoses and organic acids such as acetic acid, ferulic acid, glucuronic acid interwoven together with help of glycosidic and ester bonds. The breakdown of xylan is restricted due to its heterogeneous nature and it can be overcome by xylanases which are capable of cleaving the heterogeneous β-1,4-glycoside linkage. Xylanases are abundantly present in nature (e.g., molluscs, insects and microorganisms) and several microorganisms such as bacteria, fungi, yeast, and algae are used extensively for its production. Microbial xylanases show varying substrate specificities and biochemical properties which makes it suitable for various applications in industrial and biotechnological sectors. The suitability of xylanases for its application in food and feed, paper and pulp, textile, pharmaceuticals, and lignocellulosic biorefinery has led to an increase in demand of xylanases globally. The present review gives an insight of using microbial xylanases as an “Emerging Green Tool” along with its current status and future prospective.

Introduction

The major constituent of the plant cell wall is “lignocelluloses”, as the name suggests it consists of lignin (15–20%), hemicellulose (25–30%) and cellulose (40–50%) (Gray et al. 2006 ; Singla et al. 2012 ). These components together form a three-dimensional complex network with the help of covalent and non-covalent interactions (Sánchez 2009 ). Hemicelluloses consist of xylan, a heteropolysaccharide substituted with monosaccharides such as l -arabinose, d -galactose, d -mannoses and organic acids such as acetic acid, ferulic acid, glucuronic acid interwoven together with help of glycosidic and ester bonds (Collins et al. 2005 ; Ahmed et al. 2007 ; Motta et al. 2013 ; Sharma 2017 ). Xylan is readily available in nature, followed by cellulose the second most abundant polysaccharide which covers 33% of total lignocellulosic biomass found on the globe (Collins et al. 2005 ; Polizeli et al. 2005 ; Chávez et al. 2006 ; Walia et al. 2017 ). It accounts for 15–30% in hardwoods and 7–10% in softwood (Walia et al. 2017 ). There is a need for depolymerization of this complex polymer for its efficient utilization in different industrial application. Xylanase is a group of enzymes consisting of endo -1,4-β- d -xylanases (EC 3.2.1.8), β- d -xylosidases (E.C. 3.2.1.37), α-glucuronidase (EC 3.2.1.139) acetylxylan esterase (EC 3.1.1.72), α- l -arabinofuranosidases (E.C. 3.2.1.55), p -coumaric esterase (3.1.1.B10) and ferulic acid esterase (EC 3.1.1.73) involved in the depolymerization of xylan into simple monosaccharide and xylooligosaccharides (Gomez et al. 2008 ; Juturu and Wu 2014 ; Walia et al. 2017 ; Romero-Fernández et al. 2018 ).

Xylanases are produced by different living organisms such as microorganisms, protozoans, and molluscs, and also found in the rumen of higher animals (Beg et al. 2001 ). The xylanases are mainly produced by microorganisms, e.g., bacteria, fungi, and actinomycetes at industrial scale (Motta et al. 2013 ). The utilization of lignocellulosic biomass (LCB) for production of different biochemicals such as bioethanol, enzymes, and value-added compounds has tremendously improved in recent years. It results in providing opportunities for scientists to explore the hydrolytic potential of xylanase for efficient saccharification of LCB for ethanol and xylooligosaccharides generation. Xylanase also finds application in several industries like pulp and paper bleaching, food, feed, and pharmaceuticals.

Xylanase is required in huge amount for industrial level application with characteristic properties to survive the harsh industrial level processing’s (Qiu et al. 2010 ). Therefore, there is a need to select potent microorganisms for xylanase production, followed by optimization of media components for enhanced production. The understanding of the genetic constituents of the microbe will help in deducing the mode of action of the enzyme. This will help in regulating the enzyme action for employment in desired industrial application. The microorganisms also produce other protein and metabolites with desired xylanase enzyme. Therefore, purification of the crude enzyme is a prerequisite to obtain purified enzymes. The characterization of purified xylanase will help in elucidating its stability and specificity toward different substrates. This will help in selecting the suitable industrial process in which it can be utilized. With the advent of advanced biotechnological techniques such as recombinant DNA technology, several attempts have been made to identify, isolate and clone the gene encoding for xylanase in a suitable system. This approach helps in the engineering of efficient microorganisms for enhanced xylanase production with desired properties. This review gives a comprehensive insight into xylanase classification, its mode of action, different xylanase sources with available production methods and its optimization strategies for enhanced production. The review also gives a brief idea about different strategies employed for xylanase purification and characterization, biotechnological approach for enhanced xylanase production with desired properties which are further used for different industrial applications.

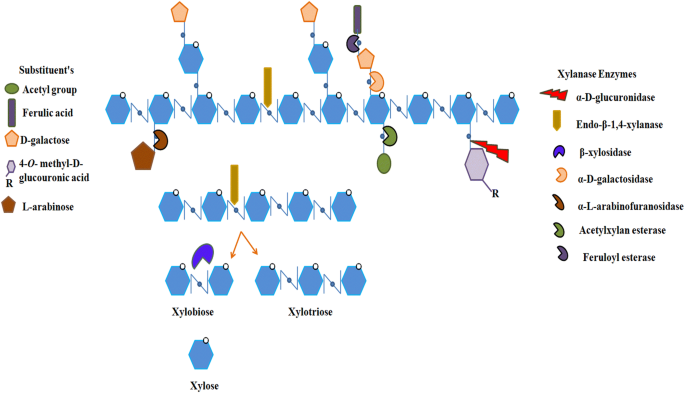

Structure of xylan and role of xylanolytic enzymes in its breakdown

Xylan consists of d -xylose backbone linked with β-1,4-glycosidic bonds and l -arabinose traces forming into a complex heteropolymeric structure. Xylan is present in various biomasses that have several forms such as in hardwoods as O -acetyl-4- O -methylglucuronoxylan, in softwoods as arabino-4- O -methylglucuronoxylan and in grasses and annual plants as arabinoxylans. These residues can be substituted with acetyl, feruloyl, glucopyranosyl, 4- O -methyl- d -glucuronopyranosyl, p -coumaroyl or α- l -arabinofuranosyl side-chain groups with varying degrees. Xylanolytic enzymes play a key role in the breakdown of the complex structure of xylan. Hence, for complete and efficient hydrolysis of xylan into its constituent sugars requires synergistic action of various enzymes with specifically targeting appropriate bonds of xylan.

The multifunction xylanolytic system exists in bacteria (Zhang et al. 2016a , 2016b ), fungi (Driss et al. 2011 ; Bhardwaj et al. 2018 ) and actinomycetes (Hunt et al. 2016 ) where xylan backbone is randomly cleaved by the action of endo -1,4-β- d -xylanases; xylose polymer is broken down to its monomeric form by action of β- d -xylosidases. Acetyl and phenolic side branches were removed by the action of α-glucuronidase and acetylxylan esterase. α- l -Arabinofuranosidases catalyze the removal of the side groups. The ester bonds present on the xylan are cleaved by the action of p -coumaric esterase and ferulic acid esterase (Beg et al. 2001 ; Collins et al. 2005 ; Chakdar et al. 2016 ; Walia et al. 2017 ). The schematic structure of xylan showing bonds which are attacked by a specific xylanolytic enzyme for complete hydrolysis of xylan to its constituent monomeric units is represented in Fig. 1 .

(Adapted from Beg et al. 2001 , Lange 2017 )

Structure of xylan showing bonds which are attacked by specific xylanolytic enzyme for complete hydrolysis of xylan to its constituents

Classification of xylanase

Xylanase can be broadly classified into three types on the basis of (a) molecular mass and isoelectric point, (b) crystal structure and (c) catalytic/kinetic property (Wong et al. 1988 ; Jeffries 1996 ; Biely et al. 1997 ; Liu and Kokare 2017 ). On basis of molecular mass and isoelectric point, the xylanase was classified into two groups, i.e., (a) high-molecular weight with low isoelectric (acidic) point (HMWLI) and (b) low-molecular weight with high isoelectric (basic) point (LMWHI). However, several exceptions to this classification have been observed where not all xylanases fall in the category of HMWLI (above 30 kDa) or LMWHI (below 30 kDa) (Collins et al. 2002 , 2005 ). Therefore, a more appropriate system including primary structure (crystal), comparison of catalytic domain with mechanistic features such as kinetic, catalytic property, substrate specificity, and product description was introduced (Henrissat and Coutinho 2001 ; Collins et al. 2005 ). The genomic, structural (3D crystal structure) and functional information of xylanase is available under glycoside hydrolase (GH) families available on carbohydrate-active enzyme (CAZy) database.

The CAZy is knowledge-based, highly curated database on enzymes that play a key role in breakdown, modification, and assembly of glycosidic bonds in carbohydrates and glycoconjugates. It consists of genomic, sequence annotation, family classifications, structural (3D crystal) and functional (biochemical) information on carbohydrate-active enzyme from publicly available resources such as National Center for Biotechnology Information, NCBI (Lombard et al. 2014 ).

The major GH families associated with xylanase are 5, 7, 8, 9, 10, 11, 12, 16, 26, 30, 43, 44, 51, and 62. The GH families 5, 7, 8, 10, 11, and 43 have a single distinct catalytic domain, whereas enzymes grouped under GH families 16, 51, and 62 have two catalytic domains with bi-functional property (Collins et al. 2005 ). The enzyme grouped under GH families 9, 12, 26, 30, and 44 has secondary xylanase activity. Based on the hydrophobic cluster analysis of the catalytic domains along with similarities studies of amino acid sequences, xylanases have been primarily classified as GH 10 and GH 11 (Verma and Satyanarayana 2012a ). The catalytic properties of GH 10 and GH 11 have been studied extensively, whereas the information on GH families 5, 7, 8 and 43 is very limited (Taibi et al. 2012 ). Different structural and functional properties of different GH families are tabulated in Table 1 .

Mode of action of xylanases grouped under various GH families

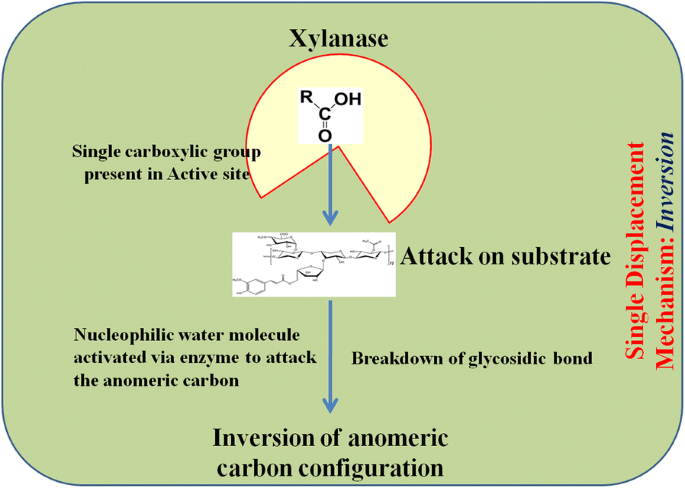

There is the difference in structure, physicochemical properties, substrate specificities and mode of action of members of GH families 5, 7, 8, 10, 11 and 43 (Collins et al. 2005 ). The hydrolysis of xylan by xylanase may occur by two different mechanisms, i.e., retention or inversion (Subramaniyan and Prema 2002 ; Lombard et al. 2014 ).

This process is represented by double displacement mechanism with α-glycosyl and oxo -carbonium intermediate formation followed by its subsequent hydrolysis. Glutamate residues play a vital role in the catalytic mechanism. First, two carboxylic acid residues present in the active site result in α-glycosyl enzyme intermediate formation. The intermediate formation occurs via protonation of the substrate by a carboxylic acid residue acting as an acid catalyst and departure of the leaving group due to nucleophilic attack caused by another carboxylic acid. This collectively results in β to α inversion due to the α-glycosyl enzyme intermediate formation. Second, the first carboxylate group abstracts a proton from a nucleophilic water molecule and attacks the anomeric carbon resulting in second substitution, where the anomeric carbon gives rise to product with the β configuration (α to β inversion) via a transition state of oxo-carbonium ions (Fig. 2 ) (Collins et al. 2005 ; Lombard et al. 2014 ). Enzymes of families 5, 7, 10, and 11 mostly work on the principle of retention.

Mode of action of xylanase: retention

The enzymes of families 8 and 43 act via inversion of the anomeric center with glutamate and aspartate as the major catalytic residue. This is a single displacement mechanism, in which only one carboxylate ion offers for overall acid catalyzed group departure (Fig. 3 ). This enzyme also acts as the base for activating a nucleophilic water molecule to attack the anomeric carbon (depending on the distance between two molecules) for breaking the glycosidic bonds and causing inversion of anomeric carbon configuration (Collins et al. 2005 ; Motta et al. 2013 ; Lombard et al. 2014 ).

Mode of action of xylanase: inversion

Several attempts have been made to understand the mode of action of xylanase obtained for different organisms. An unusual mode of action of GH8 xylanase (β-xylosidase, an α-arabinofuranosidase, and an acetylesterase activity) was observed in Pseudoalteromonas atlantica , which showed the presence of a long tail of unsubstituted xylose residue on the reducing end of oligosaccharides produced (Ray et al. 2019 ). Thermophilic xylanase obtained from Bacillus licheniformis DMS has novel hydrolysis properties similar to GH30. It breaks the linear β-(1-4) linkage of beech wood and birchwood xylan along with glucuronoxylan and arabinoxylan. B. licheniformis DMS xylanase had both the properties of endoxylanase and appendage dependent xylanase activity. It showed equal production of both xylobiose and xylotriose by hydrolysis of the commercial substrate and agro-waste such as corn cob (Ghosh et al. 2019 ).

Thermothelomyces thermophila ( Tt Xyn30A) that hydrolyzes xylan into xylose and two acidic xylooligosaccharides, namely xylotriose (MeGlcA 2 Xyl3) and xylobiose, i.e., MeGlcA 2 Xyl 2 , was studied. TtXyn30A catalyzed the release of the disaccharide xylobiose from the non-reducing end of xylooligosaccharides, thus exhibiting an exo-acting catalytic behavior. TtXyn30A also showed the capability to cleave linear parts of xylan and uronic xylooligosaccharides as well as resulting in the formation of aldotriuronic and aldotetrauronic acid (Katsimpouras et al. 2019 ). Puchart et al. ( 2018 ) have reported the mode of action of hydrolysis of eucalyptus plant using endoxylanase belonging to GH10, GH11, and GH30 family. All the endoxylanse resulted in the formation of acetylated XOS. The GH10 endoxylanase results in short xylooligosaccharides, whereas GH30 endoxylanase results in longer xylooligosaccharides. An acetyl esterase (AcXEs) played a key role in understanding the plant decay or depolymerization mechanism and also showed efficiency in plant biomass bioconversion (Rytioja et al. 2014 ).

A novel modular endoxylanase with transglycosylation activity was reported from Cellulosimicrobium sp. HY-13 belonging to GH6 family (Ham et al. 2012 ). A GH30 family xylanase XynA was reported from Erwinia chrysanthemi belonging to subfamily 8 with the special property of hydrolyzing 4- O -methyl-glucuronoxylan (Urbániková et al. 2011 ). Xyn11B from thermophilic fungus Humicola insolens Y1 encoding multi-cellular xylanase belonged to GH11 reported by Shi et al. ( 2015 ). Bacteroides intestinalis DSM17393, a xylan degrading human gut bacterium, reported the presence of two putative GH8 xylanases which hydrolyze both xylopentose and xylohexose (Hong et al. 2014 ). Endo xylanase XynB from marine bacterium Glaciecola mesophila KMM241 with xylan binding ability and GH8 catalytic domain was reported by Guo et al. ( 2013 ).

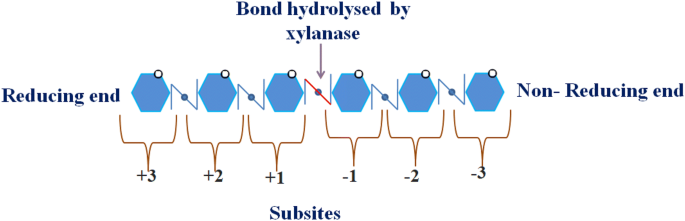

Mechanism for glycosidic hydrolase family 10 (GH10)

Among all the above-mentioned GH families, GH 10 consists of endoxylanase, e.g., endo -1,4-β-xylanases, endo -1,3-β-xylanases and cellobiohydrolases (Collins et al. 2005 ). Endo -1,4-β-xylanases or xylanase mainly comes under this GH10 family. It usually consists of high-molecular weight xylanase with low isoelectric points and displays an (α/β) 8 -barrel fold. This structure mimics the shape of a ‘Salad Bowl’, because of an enlarged loop architecture, one face of the molecule is having ~ 45 Å large radius and the other face is having ~ 30 Å radius because of simple (α/β) turns (Zhang et al. 2016a , 2016b ). However, these two categories are relatively the same because along with sharing similar fold also shares some common residues and has similar catalytic mechanisms. The xylanase belonging to GH 10 family has low substrate specificity and, however, exhibits high catalytic versatility than that of GH 11 family. Xylanase belonging to GH10 family exhibits greater catalytic versatility and lower substrate specificity as compared to those belonging to GH11 (Biely et al. 1997 ; Faulds et al. 2006 ; Motta et al. 2013 ). GH10 xylanase attacks the xylose linkages which are closer to the side-chain residues (Dodd and Cann 2009 ). This could be explained by fact that the xylose residues bind at subsites (Fig. 4 ) on xylanase that causes cleavage of the bond between the monomeric residues at the non-reducing (− 1) and the reducing end (+ 1) of the polysaccharide substrate (Davies et al. 1997 ).

Schematic representation of site for attack of GH10 xylanase on xylan

Maslen et al. ( 2007 ) demonstrated that when arabinoxylan was hydrolyzed by GH10 and GH11 xylanase, the products generated have arabinose residues substituted on xylose at the + 1 subsite and + 2 subsites, respectively. Therefore, xylanases from family 11 and 10 preferentially cleave the unsubstituted regions of the arabinoxylan backbone and the unhampered substituted regions along the xylan backbone (Biely et al. 1997 ; Motta et al. 2013 ). The degree of side-chain decorations of xylan influences the specificity of the enzyme toward substrates and, thus, has an important implication on the hydrolytic product formation by xylan deconstruction (Dodd and Cann 2009 ). Yang and Han ( 2018 ) demonstrated the positional binding and substrate interaction of GH10 xylanase of Thermotoga maritime using molecular docking approach.

Researchers have reported in their previous studies that GH10 endoxylanase had better performance than GH11 in synergy with cellulase enzyme for pretreated lignocellulosic biomass hydrolysis. The reason behind this may be because GH11 endoxylanase has the lower accessibility toward acetylated xylan backbone (Faulds et al. 2006 ). Hu et al. ( 2011 ) proposed a model holocellulosic substrate, i.e., mixture of pure cellulose and 10% pre-deacetylated commercial birchwood xylan to understand the synergism between two family xylanase and cellulase (during the xylan extraction process). This study showed that substrate deacetylation has increased the hydrolytic performance of GH11 as the acetyl group restricted the accessibility of xylan more for GH11 than GH10. Thermostability is the second factor for better performance of GH10 endoxylanase over GH11 because lignocellulosic biomass hydrolysis occurs better at high temperature (50 °C) and 2–3 days long-time duration.

Source for xylanase production

The xylanase is ubiquitous in nature and its presence is observed diversely in a wide range of living organisms, such as marine, terrestrial and rumen bacteria (Chakdar et al. 2016 ), thermophilic and mesophilic fungi (Chadha et al. 2019 ; Singh et al. 2019 ), protozoa (Devillard et al. 1999 ; Béra-Maillet et al. 2005 ), crustaceans (Izumi et al. 1997 ), snails (Suzuki et al. 1991 ), insects (Brennan et al. 2004 ), algae (Jensen et al. 2018 ), plants and seeds (immature cucumber seeds and germinating barley) (Bae et al. 2008 ; Sizova et al. 2011 ). Bacteria and fungus are widely used for industrial production of xylanase. Several microbial sources of xylanase are classified in Table 2 .

Bacterial sources of xylanase

Among bacteria, Bacillus species have been reported widely as the most potent xylanolytic enzyme producers such as Bacillus sp., B. halodurans (Gupta et al. 2015 ) , B. pumilus (Thomas et al. 2014 ), B. subtilis (Banka et al. 2014 ), B. amyloliquefaciens , B. circulans , and B. stearothermophilus (Chakdar et al. 2016 ). Xylanase with high temperature stability, acid/alkali stability, and cold adaptability have been isolated and purified from a wide range of bacteria found in extreme environment. Thermotolerant xylanase active at a very high temperature of 60–70 °C has been reported from Bacillus spp. (Thomas et al. 2014 ), Bacillus Halodurans TSEV1 (Kumar and Satyanarayana 2014 ), Clostridium thermocellum (Fernandes et al. 2015 ), Rhodothermus marinus (Karlsson et al. 2004 ), Streptomyces sp. (Sukhumsirichart et al. 2014 ), Stenotrophomonas maltophila (Raj et al. 2013 ), Thermotoga thermarum (Shi et al. 2013 ). Psychrophilic xylanases are not very common but found to be isolated from several bacteria such as Clostridium sp. PXLY1 (Akila and Chandra 2003 ), Flavobacterium sp. MSY-2 and Flavobacterium frigidarium (Humphry et al. 2001 ; Dornez et al. 2011 ) Pseudoalteromonas haloplanktis TAH3A (Van Petegem et al. 2002 ).

Several alkali stable xylanases have been isolated from firmicutes such as B. pumilus (Thomas et al. 2014 ), B. halodurans TSEV1 (Kumar and Satyanarayana 2014 ) and Geobacillus thermoleovorans (Verma and Satyanarayana 2012b ) and actinomycetes such as Actinomadura sp. Cpt20 (Taibi et al. 2012 ) and Streptomyces althioticus LMZM (Luo et al. 2016 ).

Fungal sources of xylanases

The mesophilic fungi of genera Aspergillus and Trichoderma are well known to be potent xylanase producer and most widely used for commercial production. Thielavia terrestris, (Garcia-Huante et al. 2017 ) , Talaromyces thermophilus (Maalej et al. 2009 ), Paecilomyces thermophile (Fan et al. 2012 ), Achaetomium sp. X2-8 (Chadha et al. 2019 ), Rhizomucor pusillus (Hüttner et al. 2018 ), Rasamsonia emersonii, (Martínez et al. 2016 ) T. Leycettanus (Wang et al. 2017 ) , Melanocarpus albomyces (Gupta et al. 2013 ) and Aspergillus oryzae LC1 (Bhardwaj et al. 2019 ) were found to be producer of hyper-thermophilic active xylanase. Several alkali stable xylanases were obtained from different fungal strains such as Paenibacillus barcinonensis (Valenzuela et al. 2010 ) , Aspergillus fumigatus MA28 (Bajaj and Abbass 2011 ), Cladosporium oxysporum (Guan et al. 2016 ) and Aspergillus oryzae LC1 (Bhardwaj et al. 2019 ).

Strategies employed for xylanase production from different microbial sources

The production of xylanase from microorganisms is affected by the fermentation process employed, choice of substrate and different media components. These components are often regulated by different process optimization for enhanced production of the enzyme for its application at large scale.

Different fermentation process employed for xylanase production: submerged and solid-state fermentation

Xylanases are produced by a different fermentation process using various microorganisms. The better understanding of the physiology and different metabolic processes of the microbial system has led to an improvement in the fermentation process. However, there is still an opportunity to improve the yield of enzymes. The optimization of the xylanase production will be discussed in a later section.

The xylanase production has been carried out under submerged fermentation (SmF) and solid-state fermentation (SSF) (Motta et al. 2013 ). The choice of the fermentation process usually depends on the type of microorganisms used (Table 3 ). Bacteria require a high amount of water during growth; therefore, SmF is preferred whereas fungi due to its mycelia nature require less moisture and can be grown under SSF (Walia et al. 2017 ). Several reports suggest that submerged fermentation using bacteria and fungi is the most preferred method for xylanase production. Statistically speaking approximately 90% of total xylanase is produced globally through SmF. During SmF, the synergistic effect of different xylan degrading enzymes can be observed and even result in better biomass utilization for enhanced xylanase production (Polizeli et al. 2005 ; Bajpai 2014 ). Xylanase production utilizes soybean residues and rice straw as a substrate under SmF by Aspergillus oryzae LC1 and Aspergillus foetidus (Bhardwaj et al. 2017 ; De Queiroz Brito Cunha et al. 2018a , b ). Similarly, Irfan et al. ( 2016 ) suggested the production of xylanase under SmF by B. subtilis BS04 and B. megaterium BM07. Different advantages of the SmF are homogenous condition throughout medium; method is well characterized and can be easily scaled up (Guleria et al. 2013 ). There are some disadvantages to SmF as well which limit its industrial application, i.e., high maintenance cost, energy intensive and complex downstream (Virupakshi et al. 2005 ; Walia et al. 2017 ).

Recent trends suggest that xylanase production by SSF is also gaining popularity (Walia et al. 2014 ). Bacillus sp. was used for the production of thermo-alkalophillic extracellular xylanase under SSF using wheat bran as substrate (Kamble and Jadhav 2012 ). Similarly, SSF of Trichoderma koeningi using corn cob supplemented with pineapple peel powder showed enhanced production of xylanase (Bandikari et al. 2014 ). It has several advantages such as low cultivation, operation and capital cost, a lower rate of contamination, easy enzyme recovery, and high productivity per reactor volume. The disadvantages associated with SSF are not suitable for all microorganisms (preferred for the fungal system) and require proper aeration and humidity control and up-scaling is a tedious process (Mienda et al. 2011 ).

Selection of suitable substrate for xylanase production

Quantity and quality of the fermentation product vary with different substrates. There are various commercially available substrates, i.e., xylan, carboxymethyl cellulose (CMC), pectin, and starch for, i.e., xylanase, cellulase, pectinase, and amylase, respectively (Barman et al. 2015 ; Bhardwaj et al. 2017 ; Kumar et al. 2018a ). Due to the high cost of commercial substrates and considering the economic feasibility of the process, scientists are working from past several years to find alternative substrates for the production of these enzymes.

Agrowastes and other organic wastes (domestic and industrial) are used as a carbon source for the production of xylanase with the focus on sustainability and best utilization of these wastes (Table 3 ). Some of the most commonly used agro-residues for xylanase production are wheat bran, wheat husk (Kumar et al. 2018a , b , c , d ), rice straw (Bhardwaj et al. 2017 ), rice husk, sugarcane bagasse (Suleman and Aujla 2016 ), coconut coir, coconut oil cake (Rosmine et al. 2019 ), groundnut shell (Namasivayam et al. 2015 ), wood pulp (Kalpana and Rajeswari 2015 ), sawdust, chilli post-harvest (Sindhu et al. 2017 ), corncobs, molasses, sugar beet pulp fruit, and vegetable waste (Bandikari et al. 2014 ). Recent studies also showed that wastewater from pulp industry was reused as media for xylanase production (de Queiroz-Fernandes et al. 2017 ).

Role of important media components used for xylanase production

Naturally, xylanolytic enzymes are induced by the different intermediate products generated by their own action. Xylan is found to be best xylanase inducer (Taibi et al. 2012 ; Guleria et al. 2013 ; Walia et al. 2013 , 2014 ). However, xylan being a high-molecular weight polymer cannot stimulate xylanase as it cannot enter the microbial cells. Therefore, a small amount of constitutive enzyme produced in the media results in the generation of low-molecular weight fragments, i.e., xylobiose, xylotriose, xylotetraose, xylose from the breakdown of xylan and further induces the xylanolytic enzymes for enhanced enzyme production (Walia et al. 2017 ). Cellulose, synthetic alkyl, aryl β- d xylosides, and methyl β- d -xyloside also act as an inducer for xylanolytic enzyme production (Thomas et al. 2013 ). Busk and Lange ( 2013 ) observed that poor quality paper can efficiently induce the xylanase production in Thermoascus aurantiacus even in the absence of xylan and xylooligosaccharides.

Nitrogen is an important structural element required for the metabolic processes in the microbial system. Therefore, the choice of nitrogen source is important for the growth of microorganisms that subsequently affect the overall enzyme yield. Peptone, tryptone, soymeal, yeast extract, etc. have found to be suitable nitrogen source. The requirement of these nitrogen sources varies for different microorganisms; therefore, optimizing the type and level of nitrogen source in the media is an important parameter (Seyis and Aksoz 2005 ; Naveen et al. 2014 ; Irfan et al. 2016 ). Trace elements, amino acids, and vitamins are also important parameters for the growth of different microorganisms (Simair et al. 2010 ; Bibra et al. 2018 ). Therefore, regulating their levels in the media is important for regulating the production of xylanase. Also, the addition of biosurfactant such as Tween 80 affected the level of xylanase production (Liu et al. 2006 ; Kumar et al. 2013 ).

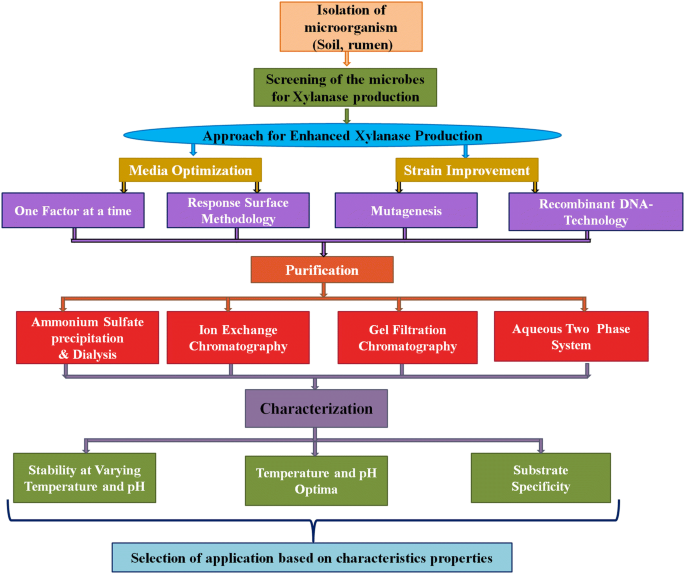

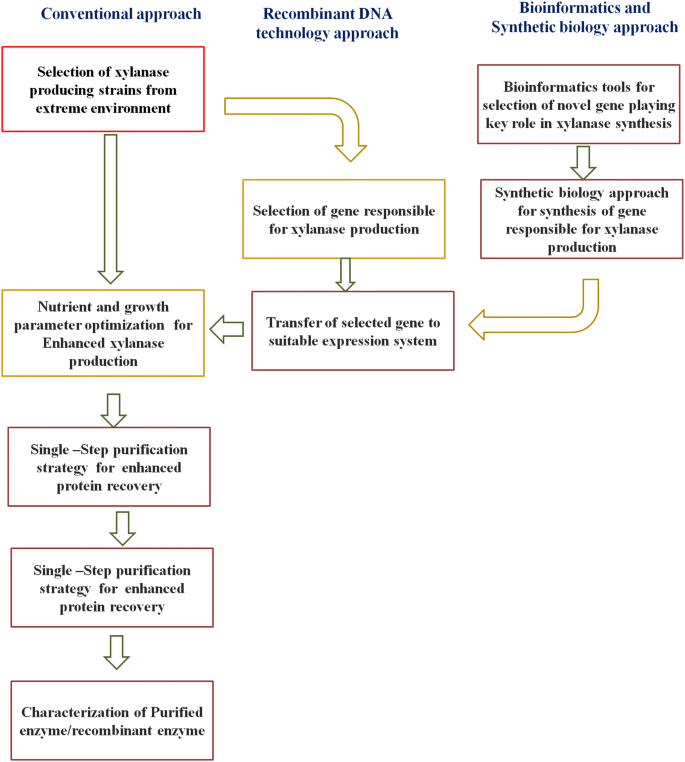

Strategies employed for the selection of the method of xylanase production and its optimization

Intially a common minimal media providing essential nutrients to the growth of microorganisms are used. This will allow to check the strains are capable of producing required enzymes/metabolite of desired interest. Then, the process is further optimized for higher production of enzymes from the strain (Walia et al. 2017 ). For the production of desired product, different strategies are used for improving yield such as optimization of media components, regulating physical growth parameters, and improving the strain by use of the different biotechnological tool (Sharma 2017 ). The schematic representation of the methodology adapted for production, purification and characterization of xylanase are shown in Fig. 5 . In this section, the focus will be on the optimization of media and growth parameters and biotechnological tool approach will be discussed in a later section. During SmF for enzyme production, different components which need to be optimized are selection of substrate and microorganisms, regulation of nutrients concentration in media, i.e., carbon, nitrogen, trace elements, vitamins and amino acids, and physical parameters, i.e., temperature, pH, agitation, aeration, inoculum sizes, and incubation period (Motta et al. 2013 ; Walia et al. 2015a , 2017 ).

Schematic representation of the methodology for production, purification and characterization of xylanase

During optimization of the SSF, there is requirement of regulating particle size, pretreatment, humidity, water content and water activity (a w ) of substrate, type and size of the inoculums, removal of extra heat generated during microbial metabolism and most importantly maintaining the uniform environment (temperature) and evolution of CO 2 and consumption of O 2 , i.e., gaseous system (Murugan et al. 2011 ; Behera and Ray 2016 ; Behnam et al. 2016 ; Leite et al. 2016 ; Walia et al. 2017 ).

Approach for enhanced xylanase production: one factor at a time (OFAT)

To proceed for the optimization of the xylanase production, one factor at a time (OFAT) approach is used for the selection of important factors affecting the xylanase yield. In the OFAT approach, one factor is kept variable keeping other factors at constant (Bhardwaj et al. 2018 ). The factor may be important physical or nutritional parameters regulating the growth of microorganisms and its enzyme yield. Ramanjaneyulu et al. ( 2017 ) have evaluated several operating parameters for nutritional (different substrates and their concentrations, additional carbon and nitrogen sources) and physical factors (incubation temperature, pH, agitation) along with inoculum size of Fusarium sp. BVKT R2 in a shake flask culture (SmF) by OFAT approach. The high xylanase yield of 4200 U/mL was obtained with birch wood xylan in mineral salt medium with 1.5% sorbitol (additional carbon source), 1.5% yeast extract (nitrogen source) at temperature of 30 °C, pH of 5.0, agitation of 200 rpm and inoculum of agar plugs (6) for only 5 days incubation. Under unoptimized condition, xylanase yield was only 1290 U/mL after 7 days of incubation, thus improving by 3.2-fold. Bhardwaj et al. ( 2018 ) also optimized xylanase production using Aspergillus oryzae LC1 using OFAT approach. The physical parameters (liquid to solid ratio, pH, inoculums size, incubation time and temperature) and nutrient parameters (substrate concentration) were optimized using OFAT approach for enhanced production of xylanase by T. viride -IR05 under SSF (Irfan et al. 2014 ).

Statistical approach for enhanced xylanase production

The OFAT approach is tedious and requires a large set of experiments for optimization. The recent trend suggested the application of the statistical approach to design experiments considering different factors as variable and performing the interaction studies among several physical and nutritional parameters. The statistical-based approach has shown satisfactory results for optimization of xylanase production using fungal and bacterial strains with the minimum number of experimental sets (Guleria et al. 2015 , 2016a ; Walia et al. 2015b ; Bhardwaj et al. 2017 ).

Response surface methodology (RSM) was employed to optimize the fermentation medium constituents and the physical factors affecting xylanase production using Bacillus tequilensis strain ARMATI under SmF (Khusro et al. 2016 ). The experimental design consists of central composite design (CCD) with four (4) independent variable (carbon and nitrogen source, temperature and time) resulting in 30 experimental runs. The central composite design gave an optimum parameter for studied variable (1.5% w/v birchwood xylan, 1% w/v yeast extract, temperature 40 °C, time 24 h) showing 3.7-fold enhanced xylanase production as compared to OFAT. High coefficient of determination (R 2 ) of 0.9978 with p < 0.05 as obtained by analysis of variance (ANOVA) analysis suggested the accuracy of the overall process at a significant level. The R 2 value of 0.9978 represents that sample variation of 99.78% and only 0.21% of the total variation in the response cannot be explained by the model. The xylanase obtained has shown high thermal (60 °C) and alkali stability (pH 9). Bhardwaj et al. ( 2017 ) optimized nutritional components (rice straw, MgSO 4 , and CaCl 2 concentration) and physical parameters (temperature and pH) for enhanced xylanase production with an Aspergillus oryzae LC1 under submerged fermentation using CCD-RSM. The statistical design suggested optimum condition of 1% rice straw (w/v), 1.0 g/L CaCl 2 , and 0.3 g/L MgSO 4 , with pH 5 and 25 °C. It resulted in maximum xylanase activity of 935 ± 2.3 IU/mL which is 3.8-fold higher than the un-optimized Mendel’s Stenberg Basal Salt medium (245 ± 1.9 IU/mL). The enzyme showed thermal (25–60 °C) and pH (3–10) stability. The xylanase also showed potential for efficient enzymatic hydrolysis of different lignocellulosic agro-residues.

Similarly, Tai et al. ( 2019 ) reported the optimization of five physical and two nutritional parameters using the RSM approach for enhanced xylanase production. Indigenous fungus Aspergillus niger DWA8 was grown under SSF on an oil palm frond. One physical (moisture content 75%) and one nutritional parameters (substrate concentration 2.5 g) have significant effect on xylanase production. Under optimum condition, an increase in xylanase yield by 78.5% was observed as compared to an un-optimized condition. The xylanase was efficiently used for saccharification of biomass. The statistical optimization method for enhanced xylanase production has been applied and widely accepted for SSF and SmF that helped in overcoming several limitations of classical empirical (OFAT) methods.

Biotechnological approach for enhanced xylanase production

There is a need of high yield of the enzyme with specific properties such as high stability over a wide range of temperature and pH, high substrate specificity and strong resistance to metal cations and chemicals for the industrial application (Garg et al. 2010 ; Qiu et al. 2010 ). The native enzyme is usually produced in low quantity and also lacks all the characteristics to meet the industrial needs (Ahmed et al. 2009 ). Therefore, different biotechnological approaches are used for improving the yield and imparting characteristic properties to the desired enzyme. These approaches involve genetic manipulation involving mutation and recombinant DNA technology.

Mutagenesis of microorganisms for enhanced xylanase production

Several researchers suggested that the application of physical mutagens such as UV radiation (Rahim et al. 2009 ; Abdel-Aziz et al. 2011 ) and chemical mutagens such as N -methyl N -nitro N -nitroso guanidine (MNNG) (Haq et al. 2004 , 2008 ) resulted in enhanced xylanase production. Burlacu et al. ( 2017 ) demonstrated the improvement of xylanase production in fungal strains, i.e., Aspergillus brasiliensis and Penicillium digitatum by physical mutagenesis (5–50 min, exposure to UV light) and chemical mutagenesis (150 µg/mL of N -methyl- N ′-nitro- N -nitrosoguanidine or ethyl methane sulfonate). The exposure to physical and chemical mutagens has resulted in significant changes in the mutant strain as compared to the wild type. Han et al. ( 2017 ) demonstrated the site-directed mutagenesis of XynCDBFV gene of ruminal fungus Neocallimastix patriciarum for improving the thermostability of XynCDBFV, a glycoside hydrolase (GH) family 11 xylanase. Similar work has also been carried out in different bacterial strains, a rifampin-resistant mutant of Cellulomonas biazotea , designated 7Rf, resulting in elevated levels of xylanases production as compared to the parental strain. After mutation, maximum xylanase and β-xylosidase production of 493 IU/L/h and 30.7 IU/L/h of β-xylosidase were obtained respectively. This increase in xylanase and β-xylosidase yield were 1.21- and 2.29-fold higher respectively as compared to the parental strain (Rajoka et al. 1997 ). Bacillus mojavensis PTCC 1723 when subjected to UV light exposure (280 nm, 30 s) resulted in the xylanase yield 330.6 IU/mL which is 3.45 times higher as compared to 95.7 IU/mL for wild strain (Ghazi et al. 2014 ). Lu et al. ( 2016 ) demonstrated mutation of XynHB, alkaline stable xylanase from Bacillus pumilus HBP8 at N188A. The mutant XynHBN188A is expressed in E. coli and Pichia pastoris with improved xylanase yield by 1.5- and 7.5-fold, respectively. The codon-based optimization and high-density fermentation using Pichia pastoris system were utilized for improving the xylanase yield.

Gene cloning and expression of xylanase genes using recombinant DNA

The recombinant xylanases are designed to have equivalent or better properties than the wild-type enzymes with high yield in the expression system which can be employed in the fermentation industry. The highly thermo-alkalophilic xylanase producing strains can be directly employed during simultaneous saccharification and fermentation for ethanol generation using lignocellulosic biomass. The inherited stability will enable the xylanase to work efficiently even at high temperature and varying pH range of the fermentation system.

Several reports suggests that desired xylanase gene was cloned into the suitable vector followed by its expression in the suitable microbial systems such as bacteria, yeasts, and fungus (Belancic et al. 1995 ; Goswami et al. 2014 ; Jhamb and Sahoo 2012 ; Juturu and Wu 2012 ; Motta et al. 2013 ; Nevalainen and Peterson 2014 ; Verma et al. 2013 ).

Expression in bacteria

Goswami et al. ( 2014 ) demonstrated the expression of a xylanase gene from Bacillus brevis in E. coli BL21. The recombinant strain predominantly secreted xylanase in the culture medium with 30 IU/mL xylanase activity. The culture filtrate is free from cellulase activity and found to be active in a wide range of pH and temperature. A thermo-alkali stable xylanase encoding gene (Mxyl) was retrieved from compost-soil metagenome library construct and cloned into pET28a vector expressed in E. coli BL21(DE3). The recombinant xylanase has shown half-life of 2 h and 15 min at 80 °C and 90 °C, respectively. The recombinant xylanase has pH and temperature optima of 9.0 and 90 °C, respectively (Verma et al. 2013 ).

Escherichia coli is preferred and most widely used expression host due to its inexpensive growth conditions, easy manipulation, simple transformation techniques requirement, high level of product accumulation in the cell cytoplasm (Jhamb and Sahoo 2012 ). However, efficient and functional expression of many xylanase genes is not possible with E. coli which may be due to repetitive appearance of rare codons and the requirement for specific translational modifications (disulfide-bond formation and glycosylation) (Belancic et al. 1995 ; Jhamb and Sahoo 2012 ; Juturu and Wu 2012 ; Motta et al. 2013 ). One of the other important concerns associated with E. coli is the presence of endotoxins (lipopolysaccharide) which makes the protein purification process very tedious. Lactobacillus and Bacillus species are used for heterologous expression of xylanase than in E. coli . It is capable of performing N-glycosylation, generally regarded as safe (GRAS) due to the absence of endotoxins and their secretory production is beneficial in industries (Bron et al. 1998 ; Subramaniyan and Prema 2002 ; Upreti et al. 2003 ; Juturu and Wu 2012 ). Zhang et al. ( 2010a , b ) demonstrated the expression and characterization of the xylanase gene (xynB) from Dictyoglomus thermophilum Rt46B.1 in Bacillus subtilis system. The pH and temperature optima for the purified recombinant enzyme were 6.5 and 85 °C, respectively. The xylanase was stable up to 95 °C and retained its activity in surfactants such as EDTA, DTT, Tween-20 and Triton X-100.

Expression in yeast

The heterologous protein expression in yeast system is highly attractive due to its ability to perform eukaryotic post-translational modifications and can grow to very higher cell densities with the ability to secrete enzyme into the fermentation system. Most of the yeasts are considered as GRAS organisms and do not produce toxins (Juturu and Wu 2012 ). Saccharomyces cerevisiae already established as an industrial microorganism, thus, can be conveniently used for xylanase production (Ahmed et al. 2009 ).

The application of Pichia pastoris as expression system has gained impetuous because it can promote the expression of the protein on their own using alcohol oxidase as promoter using methanol utilization pathway (Ahmed et al. 2009 ; Juturu and Wu 2012 ; Motta et al. 2013 ). Pichia pastoris as expression system is preferred as it can grow to very high cell densities, inherit strong and tightly regulated promoters, and produce high titer of recombinant protein (g/L) both intracellularly and in the secretory manner (Ahmad et al. 2014 ). Basit et al. ( 2018 ) demonstrated the cloning of two GH11 xylanase genes, MYCTH_56237 and MYCTH_49824 , from thermophilic fungus Myceliophthora thermophila and its expression in Pichia pastoris . The specific activities of purified recombinant xylanase were observed at 1533.7 U/mg and 1412.5 U/mg for MYCTH_56237 and MYCTH_49824 , respectively. The recombinant xylanase showed stability under harsh condition (high pH and temperature) and high efficiency for biomass saccharification. However, the application of Pichia pastoris at large scale is limited due to health and fire hazards of methanol (Ahmed et al. 2009 ). In the case of P. pastoris as expression system, lower protein yield was obtained while expressing membrane-attached protein or proteolytic degradation prone protein and complex protein such as hetero-oligomers (Ahmad et al. 2014 ).

Expression in filamentous fungi

Filamentous fungi can be efficiently used for heterologous and homologous gene expression resulting in high yield of recombinant gene products (Su et al. 2012 ; Motta et al. 2013 ; Nevalainen and Peterson 2014 ; Nevalainen et al. 2018 ). Similar to yeast, it can regulate expression yields with their own promoters and can provide eukaryotic style post-translational modification of proteins such as N-glycosylation, proteolytic processing, or formation of multiple disulfide bonds (Ahmed et al. 2009 ; Fleissner and Dersch 2010 ; Landowski et al. 2015 ).

The application of fungi as an expression system also has advantages associated with cost-effectiveness of the overall process due to low-cost substrate and downstream processing. Further, fungi have already been subjected to many strain improvement procedures for enhanced production of xylanase. Therefore, the native xylanase expressing machinery can be efficiently used for functional expression of a foreign xylanase gene from other sources. Xyn2 xylanase gene was expressed in T. reesei by homologous expression resulting in the 1.61 g/L of xylanase 2 on glucose-containing medium (Li et al. 2012 ). Godlewski et al. ( 2009 ) demonstrated xylanase B(XynB) gene expression in T. reesei. Similarly, the expression of xylanase 2 (XYN2) and xylanase gene from the thermophilic fungus Humicola grisea var. thermoidea and P. griseofulvum was expressed in Trichoderma reesei and Aspergillus oryzae , respectively (De Faria et al. 2002 ; Motta et al. 2013 ). Nevalainen and Peterson ( 2014 ) presented a comprehensive review on application of filamentous fungus as expression system and suggested that research is now focused on understanding the cellular mechanisms for better internal protein quality control and secretion stress. The better utilization of “omics” tools can help in improving the regulation of xylanase production using filamentous fungus as an expression system.

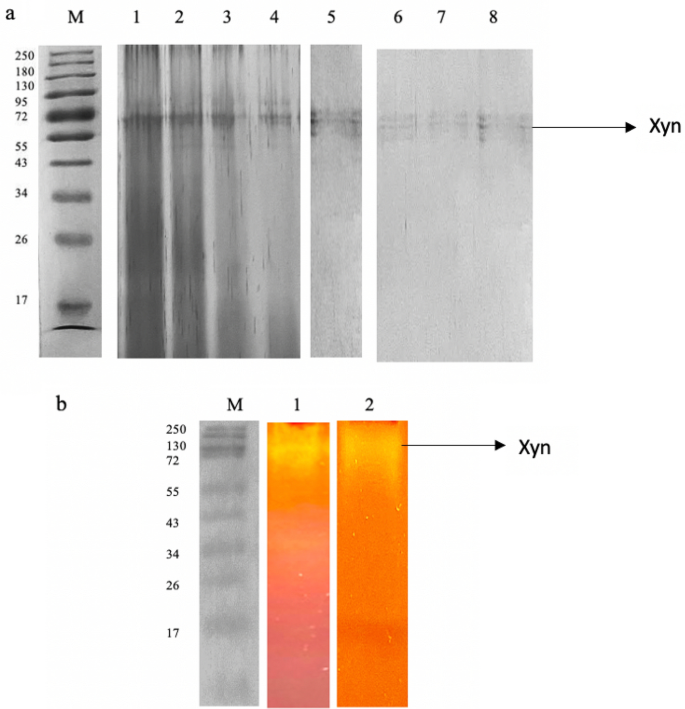

Strategies for enhanced purification and characterization of xylanase for industrial application

The microbial system produces a wide range of biochemical’s during different growth and development of the microorganisms. These biochemical’s are enzymes, secondary metabolites, etc. which are of great importance to human applications. Similarly, enzymes are produced by microorganisms along with other enzymes or metabolites. Therefore, purification is prerequisites for obtaining pure enzyme with minimum or no impurities (Zhang et al. 2012 ). The characterization of the purified enzyme such as evaluation of temperature and pH optimum, thermal and acid/alkali stability, role of metal ions and inhibitors in regulation of enzyme activity, and substrates specificity was performed for selecting the suitable industrial process (Bhardwaj et al. 2019 ). There are different enzyme purification strategies for the xylanase such as ammonium sulfate precipitation (salting in) followed by dialysis (salting out), gel permeation chromatography, ion exchange chromatography, recently developed techniques aqueous phase chromatography and ultrafiltration (Walia et al. 2014 ; Guleria et al. 2016b ; Bhardwaj et al. 2019 ).

Ammonium sulfate precipitation followed by dialysis

The crude xylanase preparation is subjected to different ranges of ammonium sulfate concentration (30–90%) for selection of suitable salt concentration for precipitation of the enzyme. The precipitated enzyme is then subjected to dialysis for removal of the salt. The crude xylanase obtained from Streptomyces P12-137 was subjected to ammonium sulfate precipitation (40–90%) followed by dialysis. The purification fold of 4.18 was observed with two different endoxylanase observed as F5 (65%) and F6 (80%) with the specific activity of 45.4 U/mg and 36.5 U/mg, respectively. This was also confirmed by HPLC analysis. The purified enzyme was further characterized by incubating at different temperature and pH followed by analyzing the enzyme for xylanase activity. The optimum pH and temperature of pH 7.0, 60 °C and 6.5, 60 °C, for F5 and F6 xylanase, respectively, were obtained (Coman et al. 2013 ).

Bhardwaj et al. ( 2017 ) performed partial purification of the crude xylanase obtained from Aspergillus oryzae LC1 using ammonium sulfate (60%) precipitation followed by dialysis against 50 mM acetate buffer (pH 5.0). The partially purified enzyme was further characterized which showed stability over a wide pH range of 3 to 10 and thermal stability over the temperature range of 25 to 60 °C. Similarly, Kumar et al. ( 2018d ) have demonstrated the purification and characterization of xylanase obtained from sea sediment bacteria using a combination of ammonium sulfate precipitation and dialysis. The improvement in specific activity and characteristic properties of xylanase was observed. The major limitations of the precipitation are needed to remove salt from protein sample so further processing in the form of dialysis or chromatography is required. Further, for dialysis, there is a need to have a better understanding of the protein solubility. It is also stated that ammonium precipitation concentrates the protein rather than purifying it. Thus, contaminant present in the crude sample may also be present along with the protein sample even after precipitation and dialysis (Biosciences 2019 ). The xylanase is also concentrated or precipitated using trichloroacetic acid (TCA) and acetone. However, the TCA may denature the protein; therefore, it is not advisable to use TCA when the protein is required in the folded state (for activity assay) and the toxicity of TCA also limits its applications (Koontz 2014 ).

Chromatography techniques for enhanced xylanase yield employed for purification

Usually, it has been observed that xylanase purification was performed by the multi-step process where the concentration of protein using ammonium acetate/TCA/acetone precipitation or ultracentrifugation was followed by a single step or series of chromatography techniques. Yadav et al. ( 2018 ) demonstrated the purification and characterization of extracellular xylanase obtained from A. kamchatkensis NASTPD13 cultures. The crude xylanase was subjected to ammonium sulfate (80%) precipitation followed by dialysis. The dialyzed sample was further subjected to Sephadex G100 column chromatography. The fractions collected showing maximum xylanase activity were concentrated and analyzed by SDS-PAGE (MW obtained was 37 kDa). The two-step purification has led to increased xylanase activity by 11-fold with a 33 U/mg specific activity. The characterization of purified protein showed pH and temperature optimum of 9.0 and 65 °C, respectively, and also retained more than 50% of its activity over a wide range of 6–9 pH and 30–65 °C temperature. An insight into several purification strategies employed for xylanase from different microorganisms along with the process efficiency in terms of recovery potential and kinetics property is tabulated in Table 4 .

Purification of endoxylanase obtained from Bacillus pumilus B20 was performed in three steps (Geetha and Gunasekaran 2017 ). The first step was ammonium sulfate precipitation (60–80%) followed by FPLC using DEAE Sepharose column as the second step and further subjecting the eluted sample onto a Sephacryl S-200 column as the third purification step. At each step, the specific activity was improved as compared to the crude enzyme by 5 to 14.8-fold with maximum 755.8 U/mg specific activity at the end of all the three purification steps. After the purification, the fractions showing maximum xylanase activity were subjected to xylanase assay and other characterization studies such as SDS-PAGE, zymography, temperature and pH stability. The SDS-PAGE and zymography analysis showed the purified enzyme of ~ 85 kDa, i.e., endoxylanase (XylB). The purified enzyme was stable in a pH range of pH 6.5 to 7.5 and the temperature range of 20 to 50 °C. The purified enzyme was highly specific to different commercial and natural xylan substrate and has the potential to generate xylooligosaccharides.

Aqueous two-phase system employed for purification of xylanase

The conventional multistep purification techniques are time consuming, which increases the cost of the overall process and also results in loss of protein at each step (Iqbal et al. 2016 ; Ramakrishnan et al. 2016 ). The 60–70% of total processing cost in enzyme downstream process comes from the purification step (Loureiro et al. 2017 ; Bhardwaj et al. 2019 ). Therefore, several scientists suggested a single step liquid–liquid fractionation technique, i.e., aqueous two-phase system (Naganagouda and Mulimani 2008 ; Yasinok et al. 2010 ; Glyk et al. 2015 ).

Garai and Kumar ( 2013 ) purified alkaline xylanase from Aspergillus candidus using aqueous two-phase system (ATPS) composed of PEG 4000/NaH 2 PO 4 system. The critical factors of ATPS such as PEG molecular weight, PEG and phosphate salt concentration using Box–Behnken design approach were used for the optimization of enhanced xylanase purification. The optimum condition was PEG 4000 at 8.66% w/w with a high salt concentration of 22.4 w/w that resulted in 8.41% purification fold. The enzyme was stable at alkaline pH and activity is enhanced with Mn 2+ ions. Ng et al. ( 2018 ) demonstrated the recovery of xylanase from Bacillus subtilis fermentation broth with an alcohol/salt ATPS. The ATPS system consists of 26% (w/w) 1-propanol and 18% (w/w) ammonium sulfate resulting in 5.74 ± 0.33 purification fold and yield of 71.88% ± 0.15.

Gómez-garcía et al. ( 2018 ) demonstrated purification of xylanase by Trichoderma harzianum using ATPS with PEG/salt system. The PEG molecular weight, PEG, phosphate salt concentration, and salt conditions were optimized. The best enzyme recovery and purification fold of 62.5% and 10% respectively was obtained using 20.2% PEG 8000, 14.8% K 2 HPO 4 , and tie to a length of 45% w/w. Bhardwaj et al. ( 2019 ) subjected crude xylanase from Aspergillus oryzae LC1 to four different single-step purification by ammonium sulfate precipitation, ion exchange, gel filtration chromatography and ATPS PEG/Salt system. The xylanase purification using single-step ATPS system resulted in highest purification yield (PY) of 86.8% and 13-fold purification fold (PF) which was much higher than other purification strategy, i.e., ammonium precipitation (PY-21%, PF-4.1), anion exchange (PY-31.9%, PF-3) and gel filtration (PY-78.7%, PF-6.6).

Therefore, ATPS exhibits several advantages over traditional purification techniques, i.e., it requires low-cost materials, low energy consumption with high yield and better resolution (Naganagouda and Mulimani 2008 ; Yasinok et al. 2010 ; Glyk et al. 2015 ). The ATPS method is independent of protein concentration and does not affect the native property of protein (Iqbal et al. 2016 ; Ramakrishnan et al. 2016 ).

Structural properties of xylanase responsible for thermal and pH stability required for industrial application

The high stability of xylanase was due to the presence of intrinsic structural properties. The presence of extra disulfide and salt bridges, hydrophobic side chains, and N-terminal proline residues helps in reduction of conformational freedom of the protein structure. Thus, it help in providing more stability to protein at the higher temperature (Turunen et al. 2001 ; Chen et al. 2015 ). Different structural modifications such as high Thr/Ser ratio and high charged residues, i.e., Arg, cause enhanced polar interaction and improved stabilization of the alpha-helix region and secondary structures (Hakulinen et al. 2003 ). The xylanase protein has a large number of ion pairs/aromatic residues on the surface of protein resulting in enhanced interactions (Polizeli et al. 2005 ; Chen et al. 2015 ). The low average protein rigidity i.e. low B factor, low flexibility results in high rigidity at extreme physical conditions (Xie et al. 2014 ). The presence of divalent metal ions and removal of N or C terminal disordered residues protect xylanase from heat and protease inactivation (Andrews et al. 2004 ; Chen et al. 2015 ). The presence of carbohydrate-binding modules (CBM22 and CBM9) at N or C terminal often imparts heat stability to xylanase. The pH stability of the xylanases is often affected by the presence of several amino acids near the catalytic residues (Singh et al. 2019 ).

Cost estimation of the xylanase production

Polizeli et al. ( 2005 ) suggested that 20% of the total global enzyme production is from biomass hydrolysis enzymes, i.e., xylanase, cellulase and pectinases. An extensive study on cost involved in each step of xylanase production at industrial scale is unavailable on public domain. Klein-Marcuschamer et al. ( 2012 ) performed a study on the cost analysis of application of enzymes during the lignocellulosic biomass based biofuel production and suggested breakdown of the operating cost (annual) in their enzyme production facility. They suggested percentage of cost involved for each component, i.e., raw materials (28%), labor (7%), transportation (1%), consumables (4%), utilities (10%), facility dependent (48%), and waste treatment (2%). This clearly shows that maximum contribution of 48% comes from the capital investment followed by cost of substrate (28%). Klein-Marcuschamer et al. ( 2012 ) also suggested the baseline production cost of hydrolysis enzyme as $10.14/kg.

Da Gama Ferreira et al. ( 2018 ) performed techno-economic analysis of the β-glucosidase enzyme production from E. coli on industrial scale. They showed major cost during industrial production are facility dependent (45%) followed by raw materials (25%) and consumables (23%), that are similar to observations made by Klein-Marcuschamer et al. ( 2012 ). Capital investment/facility-dependent cost is required for development of infrastructure (i.e., equipments), insurance, maintenance and depreciation. This upstream and downstream process during enzyme production involves the cost on part of capital investment along with the cost of consumables and utilities. da Gama Ferreira et al. ( 2018 ) performed sensitivity analyses of process scale, inoculation volume with respect to volumetric productivity, which suggested that remarkable reduction in cost of enzyme production may be observed under optimized conditions. Thus, based on the above studies, we can suggest that xylanase production can be based on the cost of substrate and consumable, along with the cost of each step involved in upstream and downstream processing. Therefore, utilizing cheap raw materials, less number of steps during upstream and downstream process (such as single step purification instead of multistep process) can help in keeping the enzyme production cost as low as possible.

Xylanase employed as a greener tool in different industries

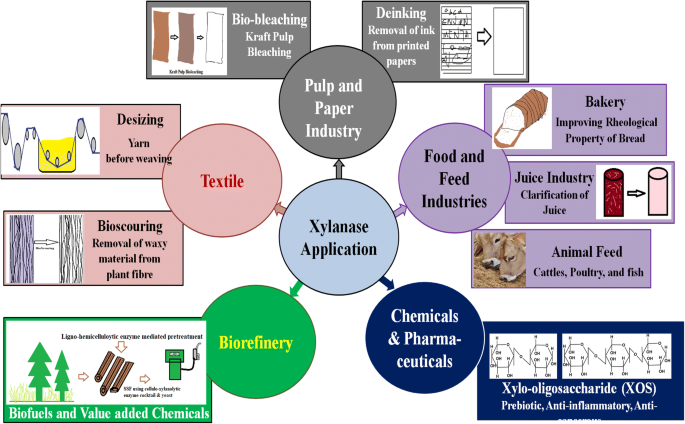

Xylanase with such unique characteristics of thermo-alkali tolerant nature has a diverse range of application in different industries such as paper and pulp, deinking, biomass utilization and food feed industries (Fig. 6 ).

Xylanase as a greener tool in different industries

Xylanase employed in the food and feed industry

The xylanase finds application in food industries such as bakery. The bread is made up of wheat consisting of hemicelluloses such as arabinoxylan. The xylanase can solubilize the water unextractable arabinoxylan into water-extractable arabinoxylan (Courtin and Delcour 2002 ). This help in uniform water distribution and improvement in gluten network formation throughout the dough. The addition of xylanase improves the rheological properties of dough such as softness, extensibility, and elasticity along with bread-specific volume and crumb firmness (Harbak and Thygesen 2002 ; Camacho and Aguilar 2003 ; Butt et al. 2008 ). The breakdown products of arabinoxylan, i.e., arabino-xylooligosaccharides in bread have its health benefits (Polizeli et al. 2005 ; Bajpai 2014 ).

Butt et al. ( 2008 ) demonstrated the role of GH11 endoxylanases from B. subtilis in solubilizing the arabinoxylan. This increases the viscosity and volume of dough and decreases gluten agglomeration and dough firmness resulting in the development of uniform and fine crumbs. GH11 xylanase (0.12 U/g flour) from Penicillium occitanis Pol6 resulted in improvement of bread-making process such as the decrease in water absorption (8%) and an increase in dough rising (36.8%), volume (17.8%), specific volume (34.9%) and cohesiveness. The bread has improved rheological and sensory properties (texture, taste, flavor, softness, and overall acceptability). Low springiness and gumminess were observed in the bread prepared using xylanase (Driss et al. 2013 ). Partially purified microbial xylanase was used by Ghoshal et al. ( 2013 ) to produce whole‐wheat bread with better sensory properties (brighter color). The addition of xylanase also resulted in increased specific volume, and shelf life, with lower firmness and reduced staling during storage. Panzea, new generation xylanase obtained from Bacillus Licheniformis , can help in improving dough properties at low enzyme dosage. It helps in achieving the desired texture, appearance, loaf volume and crumb structure (Bajpai 2014 ). Similarly, recombinant xylanase (r-XynBS27) obtained from Pichia pastoris ( xynBS27 gene from Streptomyces sp. S27) used as an additive during bread-making process. The recombinant xylanase resulted in improvement in a specific volume and reducing sugar content with a decrease in firmness, consistency, and stiffness (De Queiroz Brito Cunha et al. 2018a , b ).

Fruit juice clarification

The enzymatic process in fruit juice extraction and clarification is widely used. Raw juices of fruit contain polysaccharides such as cellulose, hemicellulose, starch pectin and surface-bound lignin and decrease the quality of the juice, e.g., hazy color and high viscosity (Danalache et al. 2018 ). The use of enzymes decreases the viscosity and avoids the formation of clusters, by removing the suspended and undissolved solid using centrifugation and filtration methods. This increases the clarity, aroma, and color of the juice (Danalache et al. 2018 ). Xylanase from Streptomyces sp was used for the clarification of orange, mousambi, and pineapple with 20.9%, 23.6% and 27.9% clarity, respectively (Rosmine et al. 2017 ). Immobilized xylanase obtained from Bacillus pumilus VLK-1 was used for orange (29%) and grape juice (26%) enrichment (Kumar et al. 2014 ). Xylanase immobilized on 1,3,5-triazine-functionalized silica-encapsulated magnetic nanoparticles was reported to clarify the three different types of fruit juices after five hours of incubation at 50 °C (Shahrestani et al. 2016 ). Partially purified xylanase from Streptomyces sp AOA40 was used in fruit juice industry for increased clarity of juices from apple (17.8%), orange (18.4%) and grape (17.9%) (Adigüzel and Tunçer 2016 ). Glutaraldehyde-activated immobilized xylanase was used for the clarification of tomato juice. Xylanase from P. acidilactici GC25 was used to treat the kiwi, apple, peach, orange, apricot, grape, and pomegranate in which increase in the amount of reducing sugar was observed along with the decrease in turbidity of the juice (Adiguzel et al. 2019 ).

Animal feed

Xylanases plays an important role in animal feed by breaking the feed ingredient arabinoxylan and reduces the raw material viscosity. Aspergillus japonicus C03 with good endoxylanase and cellulase production ability with high stability in the presence of goat ruminal environment showed ruminant feed applications (Facchini et al. 2011 ). A number of studies reported the availability of distillers dried grains with soluble (DDGS) to be utilized in animal feeds and use of exogenous xylanase in poultry diets to treat the higher fiber content (Pirgozliev et al. 2016 ; Whiting et al. 2019 ). The exogenous enzymes effectively improved the nutritional value of co-products of bioethanol as reported previously with DDGS obtained from corn (Liu et al. 2011 ). Xylanases have been involved in animal feed over decades, as it reduces the viscosity of digesta in poultry. Xylanase addition showed the weight gain improvement and enhanced feed conversion ratio because of the improvement in the arabinoxylan digestibility in monogastric animal diets (Paloheimo et al. 2010 ; Van Dorn et al. 2018 ). Xylanase utilized as a dietary supplement for the nutrients digestibility, digesta viscosity growing pigs fed corn intestinal morphology diet based on soybean meal was reported by Passos et al. ( 2015 ). ECONASE XT a well-known commercial endo -1,4-β-xylanase which has been used as feed additives for chicken fattening, weaned piglets and fattening for pigs (Rychen et al. 2018 ).

Xylanase in paper and pulp industries

Bio-bleaching.

The process of removal of lignin from wood pulp to produce bright and completely white finished paper is known as bleaching (Beg et al. 2001 ). Traditionally, chemical bleaching agents (such as chlorine) were used for bleaching (Subramaniyan and Prema 2002 ). The use of ligno-hemicellulolytic enzymes for bleaching has gained impetuous all over the world. Xylanases are capable of hydrolyzing xylan which is linked to the cellulose and lignin of the pulp fiber. Thus, xylan disruption will eventually lead to the separation between these components, enhance swelling in the fiber wall, and improve lignin extraction from the pulp (Thomas et al. 2015 ). Thus, xylanase in combination with lignin-degrading enzyme help in increasing the brightness of pulp (Viikari et al. 1994 ; Sunna and Antranikian 1997 ; Pérez et al. 2002 ; Motta et al. 2013 ). The exposures of the cellulose fiber to enzymatic pulping enhance the bonding forces of paper and improve paper strength via degradation of xylan and removal of lignin during enzymatic treatment (Lin et al. 2018 ). The enzymatic system has been highly selective, non-toxic, environmentally friendly approach for bio-bleaching (Bajpai 2012 ).

Paper and biomass pulp processing takes place at varying pH and temperature. Therefore, thermo-alkali stable xylanases are required for the bio-bleaching. An alkaliphilic Bacillus strain produced thermoactive cellulase-free xylanase using agro-residues active at high temperature 60 °C and pH 6–10 and was utilized for bio-bleaching of kraft pulp (Azeri et al. 2010 ). Paenibacillus campinasensis BL11 xylanase pretreatments showed the increased brightness and viscosity of hardwood kraft pulp (Ko et al. 2010 ). S. thermophilum xylanase active at high temperature (50–70 °C) was used for the bleaching of bagasse pulp (Joshi and Khare 2011 ). T. lanuginosus VAPS24 xylanase was stable at wide range pH that can be useful in both alkaline and acidic bioprocesses (Kumar and Shukla 2018 ). An alkaliphilic Bacillus liceniformis Alk-1 xylanase was utilized in a purified form for the enzymatic pretreatment on eucalyptus kraft pulp bleaching (Raj et al. 2018 ). The xylanase preparation obtained from white-rot fungi, S. commune ARC-11 was capable of ethanol soda pulp pre-bleaching from Eulaliopsisbinata (Gautam et al. 2018 ). The paper manufacturing units of various countries, i.e., Japan. South America, North America and Europe are slowly replacing chemical pulp bleaching by xylanase mediated pulp bleaching. Canada is known to be the leading producer of pulp and they are bleaching more than 10% its pulp via xylanase (Dhiman et al. 2008a ). In addition to that, several reports also suggest that the xylanase enzyme-mediated pretreatment can help in generation of cellulosic nanofibres (CNF) with improved crystallinity from unbleached bagasse and eucalyptus pulp (Nie et al. 2018 ; Zhang et al. 2018 ; Tao et al. 2019 ). Zhang et al. ( 2018 ) suggested that application of commercial Novozyme X2753 can simplify the CNF’s production and purification process. Tao et al. ( 2019 ) demonstrated that xylanase can directly act on the unbleached pulp, where it acts on the covalent bond between hemicellulose molecule and hydrogen bond between hemicelluloses and cellulose. The presence of a small amount of hemicelluloses in cellulose nanofibrils increases light blockage efficiency and subsequently the energy storage capacity of solar cells. Thus, xylanase-mediated bio-bleached pulp acts as a potential substrate for flexible solar cells.

Deinking of waste paper

The dislodgement of ink from the waste used paper is required for its recycling and reuse. Chemical-based methods involving chlorine or chlorine-based derivatives, ClO − , NaOH, NaCO 3 , H 2 O 2 , Na 2 SiO 2 , have been used for removing ink from the paper. This resulted in generation of hazardous effluents and required tedious treatment before disposal to the environment (Maity et al. 2012 ). The enzyme-based methods utilizing xylanase and laccase have been suggested for the removal of ink from paper and pulp industries effluents (Chandra and Singh 2012 ; Dhiman et al. 2014 ).

Virk et al. ( 2013 ) explored the deinking efficiencies of bacterial alkalophilic laccase and xylanase along with physical deinking methods such as microwave and ultrasound for recycling of waste paper. The combination of xylanase and laccase enzymes showed an increase in brightness of different waste pulp old newsprint pulp (21.6%), inkjet print pulp (4.1%), laser print pulp (3.1%), magazine pulp (8.3%), and xerox paper pulp (1.9%) only. Gupta et al. ( 2015 ) reported that synergistic action of xylanase and laccase enzyme (co-cultivation of Bacillus sp. and B. halodurans FNP135) resulted in improvement of physical properties like freeness, breaking length, burst factor and tear factor by 17.8%, 34.8%, 2.77%, and 2.4%, respectively, of old newspaper. The appearance of the newspaper was also improved with an increase in 11.8% brightness and 39% whiteness. The effective dose of commercial cellulase and xylanase from Bacillus halodurans TSEV1 for removal of ink was determined at 1.2. U/mg (each enzyme) by Kumar and Satyanarayana ( 2014 ). The cellulase and xylanase complex obtained from Escherichia coli SD5 facilitated the reduction in hexenuronic acid (Hex A) and kappa number, increase in brightness (10%) and tear strength of recycled paper (Kumar et al. 2018c ).

Xylanase employed in textile industries

The textile processing can be broadly divided into desizing, scouring and bleaching. Desizing involves removal of adhesive material from plant fibers and scouring to remove the inhibitory material from desized fibers (Hartzell et al. 1998 ; Dhiman et al. 2008b ). The conventional method used for desizing and scouring involves the application of high temperature under the influence of oxidizing agents in the alkaline system. This method is not only chemical intensive but also non-specific that causes hamper to the useful cellulosic fractions compromising the overall strength of the textile fibers. Therefore, application of highly thermo-alkali stable cellulase-free xylanolytic enzyme can efficiently be used for desizing and scouring (Csiszár et al. 2001 ; Losonczi et al. 2005 ; Dhiman et al. 2008b ; Bajpai 2014 ).

Dhiman et al. ( 2008b ) demonstrated the application of alkalo-thermophilic xylanase from Bacillus stearothermophilus SDX for processing of cotton and microply fabrics. The desizing and bioscouring treatments were performed using 5 g/L of xylanase at 70 °C, pH 9.5, for 90 min. This resulted in weight loss for 0.91% in microply and 0.83% in cotton with overall whiteness index of 11.81% for cotton and 52.15% for micropoly. The processed fabric has increased tensile strength (1.1–1.2%) and tearness value (1.6–2.4%) as compared to control.

Garg et al. ( 2013 ) demonstrated the application of alkalo-thermostable xylanase from Bacillus pumilus ASH in bioscouring of jute fabric. The oven-dried jute fabric when incubated with a small dose of 5 IU/g xylanase at 55 °C for 2 h resulted in an increase in 4.3% whiteness and 10.7% brightness of fabric. Further, it also helped in decreasing in yellowness of fabric by 5.57%. Similarly, xylanase from Bacillus pumilus was studied for enzymatic desizing of cotton and micropoly fabrics (Battan et al. 2012 ). The enzymatic desizing with enzyme load of 5 IU/g at pH 7.0, temperature 60 °C for 90 min resulted in improved whiteness of 0.9% with respect to the chemical process. The addition of surfactant such as EDTA improved the desizing and bioscouring efficiency (Losonczi et al. 2005 ; Battan et al. 2012 ; Garg et al. 2013 ).

The synergistic action of xylanase and pectinase enzyme was used for scouring of cotton fabrics. The bioscouring was performed with 5.0 IU xylanase and 4.0 IU pectinase from Bacillus pumilus strain AJK (MTCC 10414) along with surfactants such as 1.0 mM EDTA and 1% Tween-80 at high pH 8.5 for 1 h at 50 °C. They observed improvement in whiteness, brightness, and reduction in yellowness by 1.2%, 3.2%, and 4.2% respectively that is better in comparison to chemical-based alkaline scouring method (Singh et al. 2018 ). El et al. ( 2018 ) reported improvement in desizing, bioscouring and bio-finishing efficiency using xylanase obtained from T. longibrachiatum KT693225 without any requirement of additives.

Xylanase employed in chemical and pharmaceutical industries

The non-digestible sugar molecules together form oligomers known as xylooligosaccharides, which are made up of xylose monomers (Vazquez et al. 2000 ). XOS has various applications in biotechnology, pharmaceutical, food and feed industries (Chang et al. 2017 ). XOS plays a vital role as prebiotic as it is not hydrolyzed or absorbed in the gastrointestinal tract. Thus, XOS selectively stimulates the growth of important gastrointestinal microorganisms regulating the human digestive health (Roberfroid 1997 ; Collins and Gibson 1999 ; Vazquez et al. 2000 ). The potential of XOS as an efficient feed alternative is established by the fact that it help in cholesterol reduction, inhibit starch retro-gradation, improve the bioavailability of calcium thus improving the nutritional and sensory properties of food (Voragen 1998 ; Motta et al. 2013 ). XOS has shown the application in pharmaceutical sectors due to its immunomodulatory (Chen et al. 2012 ), anti-cancerous (Gupta et al. 2018 ), anti-microbial, antioxidant (Kallel et al. 2015b ), anti-allergy, anti-inflammatory (Aachary and Prapulla 2011 ), and anti-hyperlipidemic activity (Li et al. 2010 ). XOS have also shown phyto-pharmaceutical and feed applications such as growth regulatory activity in aquaculture and poultry. These properties may be due to the presence of uronic substituents in acidic oligosaccharides.

The process of XOS synthesis involves the physical (autohydrolysis), chemical (hydronium ions generated by water autoionization and in situ organic acids) or enzymatic hydrolysis (xylanase or β-xylosidase) of hemicellulose-rich agricultural wastes (Aachary and Prapulla 2011 ). Several reports suggested that XOS can be enzymatically produced from different agro-residues such as hardwoods (Huang et al. 2016 ), straws (Gullón et al. 2008 ; Kallel et al. 2015a ; Moniz et al. 2016 ) corn cobs (Chapla et al. 2013 ; Gowdhaman and Ponnusami 2015 ), bran (Otieno and Ahring 2012 ), sugarcane bagasse (Jayapal et al. 2013 ) and bamboo (Xiao et al. 2013 ) using microbial xylanases.

Alkaline xylanase from Bacillus mojavensis A21 utilized corncob xylan for the release of xylotriose and xylobiose (Haddar et al. 2012 ). Bacillus aerophilus KGJ2 xylanase showed efficiency toward XOS synthesis, e.g., xylobiose, xylotriose, and xylose after hydrolysis of xylan (Gowdhaman et al. 2014 ). A cellulase free xylanase (EX624) from Streptomyces sp. CS624 produced xylose, xylobiose and xylotriose with commercial beech wood xylan and wheat bran (Mander et al. 2014 ). Using deoiled Jatropha curcas seed cake as substrate, Sporotrichum thermophile xylanase was produced which showed the efficiency to produce XOS by the hydrolysis of oat spelt xylan, with 73% xylotetraose, 15.4% xylotriose and 10% xylobiose (Sadaf and Khare 2014 ). Xylanase obtained from the mixed microbial culture of Cellulomonas uda NCIM 2523 and Acetobacter xylinum NCIM 2526 using Prosopis juliflora showed the potential to produce XOS with probiotic activity from beech wood xylan (Anthony et al. 2016 ). A xylanase gene PbXyn10A isolated from Paenibacillus barengoltaii cloned in E. coli showed 75% XOS yield from xylan extracted from raw corncobs (Liu et al. 2018 ). The hydrolysis of xylan using xylanase from Pichia stipitis produced 2% XOS consisting of xylotetraose 14%, xylotriose 49% and xylobiose 29% (Ding et al. 2018 ). Bhardwaj et al. ( 2019 ) demonstrated the partially purified xylanase obtained from Aspergillus oryzae LC1 resulted in the generation of xylobiose, xylotriose, and xylotetraose.

Xylanase employed in biorefinery

Efficient conversion of lignocellulosic biomass (LCB) into fuel-grade ethanol has become a world priority for producing environmentally friendly renewable energy at a reasonable price for the transportation sector. The process of bioconversion of lignocellulosic biomass requires hydrolysis of the pretreated biomass for the conversion of complex carbohydrate polymer of LCB to the simple monomers which will be further converted to ethanol by fermentation. The xylanolytic enzyme in combination with cellulolytic enzyme plays an important role in the hydrolysis process.

Several reports suggest that xylanase obtained from several microorganisms plays an important role in saccharification of LCB for lignocellulosic-based biorefinery (Hu et al. 2011 ; Choudhary et al. 2014 ; Ramanjaneyulu et al. 2017 ; Basit et al. 2018 ). Hydrolysis and fermentation are important steps in biomass to bioethanol generation. Initially, several groups demonstrated separate hydrolysis of biomass followed by fermentation (SHF). SHF is a time-consuming process and thus increases the overall cost of the process. Later on, different integrated process (combined hydrolysis and fermentation) have been developed such as simultaneous saccharification and co-fermentation (SSCF), simultaneous saccharification and fermentation (SSF), and consolidated bioprocessing (CB) (Malhotra and Chapadgaonkar 2018 ). These strategies resulted in an enhancement in reaction rates and ethanol yields (Eklund and Zacchi 1995 ; Sun and Cheng 2002 ). Bibra et al. ( 2018 ) showed thermostable xylanase production using Geobacillus sp. DUSELR13, which is applied further for ethanol generation from LCB. SSF Geobacillus sp. DUSELR13 and Geobacillus thermoglucosidasius are co-cultured for SSF of prairie cord grass (PCG), and corn stover (CS). The SSF resulted in 3.53 and 3.72 g/L ethanol from PCG and CS, respectively.

Hu et al. ( 2011 ) suggested that xylanase causes fiber swelling improving porosity that helps in improving the accessibility of cellulose. To ferment both cellulose-derived hexoses (C6) and xylan-derived pentoses (C5), simultaneous saccharification and co-fermentation (SSCF) was introduced which causes ethanol production using single microorganisms co-cultured with cellulase and xylanase producing strain. Yasuda et al. ( 2014 ) demonstrated bioethanol generation by SSCF of anhydrous ammonia-pretreated Pennisetum purpureum Schumach (Napier grass) using Escherichia coli KO11 and Saccharomyces cerevisiae cellulase, and xylanase. SSCF for 96 h was reported to have a maximum 74% ethanol yield as compared to theoretical yield calculated based on glucan and xylan yield of 397 mg/g and 214 mg/g, respectively.