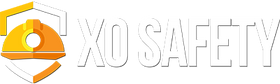

Your cart is empty Use this bar to show information about your cookie policy.  Free Forklift Safety PowerPointsTrain Your Employees To Operate Forklifts  Forklift SafetyA quick and basic look at forklift requirements. Slides : 30 Author : Instituto del Progreso Latino  Platteville School District Forklift Operator Safety TrainingSlides : 31 Author : Platteville School District  Forklift Safety TrainingXO Safety has great training options for forklift operator and instructor training. Satisfaction guarantee ● Free 30 days return ● OSHA Compliant  Business & Legal Resources 1202 Forklift Operator SafetyA brief overview of forklift safety. Author: : BLR  Washington L&I Forklift Safety PowerPointThis presentation covers all types of forklifts and gives a good overview of the basics of forklift safety. Slides : 61 Author : Washington State Department of Labor & Industries Operator TrainingXO Safety Academy's Forklift Operator Online Training Course. Instructor TrainingThe Forklift Train The Trainer Course includes everything instructors need to know about training and certifying forklift operators. This ensures that they have the "knowledge and training" required by 29 CFR 1910.178 to certify forklift operators. Training MaterialsAll the materials and documentation you need to train and certify forklift operators. Hands on operator evaluation forms are included. Downloadable Videos Compliance Kits Can Be Downloaded 30 Day Money Back Guarantee Not Satisfied? Let Us Know For A Full Refund Expert Owned Certified Safety Experts Secure payments Payment Information Not Stored Let customers speak for usGreat training tool The course met every requirement for our facility. Very informative with a lot of extra training material to download. Thank you for an excellent service provided. Very well done course. Material was relevant and engaging. I thought the course was comprehensive and thorough, It filled in a lot of gaps I had in my own knowledge The training is easy to navigate through and easy to follow. Allowed me a lot of knowledge to training my people. Sign up free Free Forklift Training Presentations for PowerPointWe’ve compiled some of the most effective forklift training PowerPoint presentations to improve your team’s safety and efficiency in operating forklifts. Convert them into interactive microlearning lessons and reduce the risk of accidents at your workplace.  Improve your forklift training by transforming them into engaging microlessonsMicrolearning breaks down complex information into bite-sized, easily digestible chunks, enhancing your team’s retention and comprehension. Soon, you can deliver forklift training as concise and focused content with SC Training (formerly EdApp)’s AI Doc Transformer (coming soon). Just upload your forklift training, and watch them transform into beautiful microlearning courses that you can instantly share with your team! Convert your free forklift training presentations for PowerPoint today!Forklift training powerpoint microlearning courses, equip your operators with the skills to safely maneuver forklifts - turn your forklift training ppt to microlessons today. In today's fast-paced and dynamic work environment, securing the safety of your team is of utmost importance. With great training material, you empower your operators to foster a culture of safety within your organization. Let SC Training (formerly EdApp) help you streamline this process. By converting your existing forklift training PowerPoint presentations into microlearning courses, you also promote on-the-go learning that integrates training into their busy schedules. SC Training (formerly EdApp) also offers ready-made courses specifically designed for forklift training. These create an effortless transition from traditional PowerPoint presentations to engaging microlearning experiences. Forklift training PowerPoint files powered industrial trucks (pit) osha 29 cfr 1910.178Pit's Are Commonly Known As Forklifts, Pallet Trucks, Rider Trucks, Powered Industrial Truck Operator Training Requirements Are Performance Oriented.  Forklift SafetyMust Be Trained And Certified; Must Drive Only The Types Of Trucks For Which They've Received Certification. Differences Between Forklifts And Automobiles.  Powered Industrial Trucks Operator TrainingCertificate Of Achievement. Powered Industrial Truck Operator's Card. 6. The Explicit Purpose Of Forklift Safety Is To Eliminate: Accidents And Injuries,. Try SC Training (formerly EdApp) for free!Reach Forklift Training Certification For forklift operators of Far West Construction and SiteServ Panel & Design Introduction - To provide a training program based on trainee’s prior knowledge

- Train operators on types of vehicles used in our workplace

- Train operators on hazards associated with Forklift operation

- Course will utilize power point, discussion, and hands-on evaluation,

- Each operator will gain the knowledge and skills needed to do their job correctly and safely.

To be covered in this course - Safety concerns

- Certification requirements

- Operator commitment to Safety

- Types, features and physics

- Forklift operations

- Load handling

- Inspecting the vehicle

- Test your knowledge

First off; What is a Powered Industrial Truck?/Forklift A mobile, power-driven vehicle used to carry, push, pull, lift or stack material. Why is Certification so important and how often do you need to be certified Having a certificate that says you have been trained means that you are compliant with OSHA regulations and are up to date on the latest safety issues. Don’t worry you only need to have a renewal every 3 years, and you will be issued with a wallet size card showing you have been trained • Keep in mind that improper operation is the most common cause of reach truck injuries and property damage. As operators, we must stay vigilant and avoid committing unsafe actions such as horseplay and stunt driving that can quickly lead to an incident. • Just as dangerous is falling victim to complacency and letting your guard down after endless hours of incident-free operation. • Remember, all it takes is one moment of carelessness to cause a serious incident. Safety Training Reduces: - ACCIDENTS by teaching correct methods of avoiding accidents

- PRODUCT DAMAGE by teaching best load handling techniques

- EQUIPMENT DAMAGE by giving instruction in correct

- operation and handling

- LOST TIME by reducing accidents, and unplanned work stoppages

Safety Training increases: OPERATOR CONFIDENCE • by showing correct methods of operation PRODUCTIVITY • by increasing operator skills EMPLOYEE MORALE • by showing management’s concern for employee health EQUIPMENT LIFE • by indicating safety check lists that help spot problems early Forklift fatalities, �1992-1996 Source: Bureau of Labor Statistics, Job Related Fatalities Involving Forklifts Forklift fatalities by age group Since a large percentage of accidents and fatalities were due to operator inexperience, OSHA mandated that operators must be trained and competent. Certification Requirements - Every forklift operator needs initial certification good for 3 years

- Refresher training is required every 3 years or sooner if the operator has been involved in an accident or near miss.

- The operator has been observed to be unsafe

- Evaluation indicated need for additional training

- Changes in the workplace affect safe forklift operation

- Or the operator is assigned to a different type of truck

- Being well trained can save your life or the life of a co-worker!

Training requirements consists of a combination of: - Formal instruction (power point presentation)

- Written exam (80% pass) (send copy to David at [email protected])

- Practical Hands on training – schedule with mike or hyrum

- Evaluation – (certification card to be presented upon successful completion of performance evaluation)

Don’t worry This Course only Covers the Reach style Types, Features, and physics In this section you will: - Create familiarity with the basic types and functions of powered industrial trucks

- Develop and understanding of the information shown on a data plate

- Understand the critical truck logistics that affect safety

- Understand the forces that cause tip-overs, and the truck design considerations and safety ratings that help prevent them, including the “stability triangle.”

Basic Types and functions Far West Construction and SiteServ both use a Reach Style forklift Forklift functions however are very basic in nature, below is shown a typical forklift and all it’s various standard parts To the left is a reach forklift – take a few minutes to take note of the various parts and the differences between the two. The load capacity data plate specifies the load each forklift can safely lift at different mast angles or when it is fitted with an attachment. The plate should display; the load capacity, lift height, load centre distance, brand and model number. The plate should also display: • Down rating of lifting capacity if a mast is fitted�• Down rating for specific attachments that are identified on the capacity plate Truck Logistics safety - While reach trucks perform the same work and function of a traditional forklift, they are a completely different machine. One of the most important differences between a reach truck and a forklift is its stability characteristics.

- Reach trucks are designed with a narrow wheel base and have front wheels that extend forward of the mast. This allows the load’s “center of gravity,” commonly called the load center, to remain within the wheel base in most cases.

- A traditional forklift has front wheels behind the mast, requiring a large counterweight to balance the load.

- The center of gravity for a properly loaded reach truck falls between the front wheels and the center of the rear axle of the truck. This area is known as the “stability triangle.”

• Lifting a load or reaching out with a load will cause the center of gravity to shift forward; traveling sideways on an incline or turning can cause the center of gravity to turn sideways. • When reaching with a load, the load center is extended beyond the front wheels. In this instance, the reach truck becomes a counterbalanced truck, but without the benefit of a large counterweight. • When reaching, the truck depends solely on the weight of the vehicle to counterbalance the weight of the load. This is why a reach truck’s rated capacity is significantly reduced when the load is extended away from the truck. • Should the center of gravity of the combined truck and load shift outside the stability triangle, the truck will turn over . This is why understanding your truck’s capacity and knowing how to read the data plate information is so important Vehicle Center of Gravity (Unloaded) Center of Gravity of Vehicle and Maximum Load (Theoretical) Stability Triangle - Figure 1 1. When the vehicle is loaded, the combined center of gravity (CG) shifts toward line B-C. Theoretically the maximum load will result in the CG at the line B-C. In actual practice, the combined CG should never be at line B-C. 2. The addition of additional counterweight will cause the truck CG to shift toward point A and result in a truck that is less stable laterally . (Line of Action) Combined CG The vehicle is stable This vehicle is unstable and will continue to tip over Stability Triangle - Figure 2 Driving the Truck safely - The tight turning radius, combined with a narrow wheel base, can easily tip even an unloaded truck when traveling too fast.

- Operators should handle their vehicles at a safe rate of speed at all times. Operators should be able to stop or turn safely at any time the need should arise.

- Remember that your vehicle is not the only thing moving about your facility. Always follow your company’s specific traffic regulations to avoid pedestrians, other vehicles and equipment.

- Intersections and blind corners should always be treated with caution. Come to a complete stop and sound your horn before proceeding cautiously into the intersection; this will alert pedestrians and other vehicle operators of your presence.

- If your facility has mirrors mounted at intersections, be sure to use them before proceeding.

- When traveling behind other vehicles, maintain a safe following distance. A good rule of thumb is to maintain three truck-lengths distance between your truck and another .

- Use extra care when overtaking other vehicles and do not pass at intersections, blind spots or heavy traffic areas.

Navigating a slope - When navigating an incline, travel at a slow, safe speed, making sure the truck is traveling straight up or down. Never travel at an angle on an incline.

- Avoid turning while on the incline. Make sure your vehicle has reached a flat surface before turning.

- When carrying a load up or down a slope, you should always face the load uphill. This improves the stability and helps the load from falling.

- When your truck is empty, however, most manufacturers recommend traveling with the forks facing downhill.

- Check your truck’s operator manual for the maximum grade on which your truck is designed to travel.

It’s the little things that count Truck/forklift operations - Trucks shall not be driven up to anyone standing in front of a bench or other fixed object.

- Unauthorized personnel shall not be permitted to ride on powered industrial trucks.

- A safe place to ride shall be provided where riding of trucks is authorized.

Watch your head - No person shall be allowed to stand or pass under the elevated portion of any truck, whether loaded or empty.

- The employer shall prohibit arms or legs from being placed between the uprights of the mast or outside the running lines of the truck.

Immobilize the forklift - When a powered industrial truck is left unattended, load engaging means shall be fully lowered,

- controls shall be neutralized,

- power shall be shut off, and brakes set.

- Wheels shall be blocked if the truck is parked on an incline

- Never leave the Forklift unattended.

A powered industrial truck is unattended when the operator is 25 ft. or more away from the vehicle which remains in his view, or whenever the operator leaves the vehicle and it is not in his view. Overhead Guard - An overhead guard shall be used as protection against falling objects. It should be noted that an overhead guard is intended to offer protection from the impact of small packages, boxes, bagged material, etc..., representative of the job application, but not to withstand the impact of a falling capacity load.

Load Backrest extension - A load backrest extension shall be used whenever necessary to minimize the possibility of the load or part of it falling rearward.

- Only approved industrial trucks shall be used in hazardous locations.

Pedestrian safety - Reach trucks pose obvious hazards to pedestrians. Your co-workers may not be familiar with the tight turning radius or the wide-swinging rear end of your vehicle.

- Pedestrians may stand too close or approach the truck while in operation. As a reach truck operator, it is your responsibility to keep the safety of pedestrians in mind at all times.

- Always allow pedestrians the right away and make sure all personnel are a safe distance away from your truck before moving.

- Never drive your truck directly towards personnel, especially if they are standing next to solid objects such as machines, racks or walls. Pedestrians can be easily crushed when operators ignore this important rule.

- The pinch points created by the moving parts of the mast are also hazardous to pedestrians. Make sure the mast area stays clear of personnel.

Lifting personnel - Besides material handling, reach trucks may also be used to lift personnel, but only when proper procedures are followed.

- To lift personnel, an approved lifting device with proper guardrails must be used. This platform must be secured to the truck with chains or pins to ensure it does not slide off the forks.

- The personnel on the platform must wear proper fall restraint devices and be sure to keep their hands away from the moving parts of the mast.

- Do not move the reach truck while the platform is raised. The platform must be lowered and the personnel must exit the platform before positioning the lift.

- Never use pallets, boards or bare forks as a lifting platform. This is extremely dangerous and has been the cause of needless injuries and fatalities.

Avoiding Tip-overs - Never travel with a raised load. A raised load brings the center of gravity toward the front of the stability triangle and the added forces of turning and braking may lead to a tip-over.

- Also do not travel while lifting, lowering, reaching or retracting a load. Stop the truck before operating these controls and always ensure the reach mechanism is fully retracted before moving.

- Always remember that extending a load away from the truck moves the load center outside the wheel base, turning your reach truck into a counterbalanced truck and reducing it’s stability. Make sure you understand your truck’s reduced capacity before reaching.

Lifting and moving loads safely - Before lifting a load, make sure the forks are spread as wide as possible for the load being lifted. Lifting a wide pallet with the forks narrowly spaced can create an unstable load.

- Before lifting or moving a load, make sure the forks are completely under the load and that the load is seated against the back of the mast. Placing the load against the back of the mast helps keep the center of gravity inside the stability triangle.

- Be aware that loosely stacked or unstable loads can shift and fall, causing injury and property damage.

- Before moving a load make sure it is stable and centered on the pallet; some loads may need to be secured before moving.

Loading safety - Collisions with fixed objects occur all too often. Inspect your path of travel before proceeding to ensure it is free of obstructions, holes, drop-offs or other hazards.

- Make sure you are familiar with all racks, walls, machinery or other objects which must be avoided.

- Don’t limit your inspection to eye level. Many reach truck collisions occur overhead when the mast or the load comes in contact with overhead obstructions such as pipes, sprinkler systems, overhead beams, lights or similar items.

- Stay alert for these items, especially when placing the load on a top rack. Maintain adequate clearance to avoid extensive property damage or injury.

Pre-operation Pre-operational Inspection - As with all powered industrial trucks, the reach truck operator must perform a pre-operational inspection before use. This will alert you to potential problems before you begin operation.

- While performing your inspection, verify that all covers, guards and safety devices are installed and functioning properly. Check around the vehicle for fluid leaks.

- Inspect the vehicle for signs of structural damage, such as bent or cracked forks.

- Check for any damage or excessive wear on the drive and load wheels.

- The lights should be in good working order and all safety decals and warning labels in place and legible.

- Inspect the battery area for signs of leaks and be sure the gate is fastened securely in position.

- Test each control mechanism to ensure proper operation, including the lift, reach and lower functions, the directional controls for both forward and reverse, the steering controls, horn, and dead man pedal.

- The dead man pedal must remain pressed for the truck to operate and will stop when released.

- Should you find any problems during your inspection, remove the vehicle from service and report the situation to your supervisor.

Congratulations on completion of this course Click Here to take the Exam  Auth with social network:Download presentation We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you! Presentation is loading. Please wait. Forklift Operator TrainingPublished by Luis Stancil Modified over 10 years ago Similar presentations Presentation on theme: "Forklift Operator Training"— Presentation transcript: Power Industrial Truck: Forklift Safety Awareness  Forklift Safety.  Forklifts and Pedestrian Safety  Powered Industrial Truck (Forklift) Refresher Course  Powered Industrial Trucks Powered Industrial Truck  Fork Truck Operation Train the Trainer - A Supplement to the S.A.F.E. Program Presented by: RCS Services.  Risk Management Department  Forklift Safety Only forklift operators may operate the forklift.  Powered Industrial Trucks - Operator Training (l) (a) (a)(2)(xiv) (b)(10) (d)  1/05 School Safety Training Forklift Operator Awareness Training WAC Note: This awareness program is NOT a complete operator training.  Lift Safety EZ Up 10’ Lift. Training Objectives Identify lift hazards Understand OSHA equipment requirements Know how to inspect equipment Take.  Front-End Loader Training.  Bob cat Skid steer loader  Copyright Progressive Business Publications 1 Forklift Safety.  © Business & Legal Reports, Inc Alabama Retail is committed to partnering with our members to create and keep safe workplaces. Be sure to check out.  POWERED INDUSTRIAL TRUCK TRAINING  Powered Industrial Trucks - Operator Training  Utility Vehicle Safety  BLR’s Safety Training Presentations About project© 2024 SlidePlayer.com Inc. All rights reserved. Newly Launched - AI Presentation Maker  - Forklift Training

- Popular Categories

AI PPT Maker Powerpoint Templates Icon Bundle Kpi Dashboard Professional Business Plans Swot Analysis Gantt Chart Business Proposal Marketing Plan Project Management Business Case Business Model Cyber Security Business PPT Digital Marketing Digital Transformation Human Resources Product Management Artificial Intelligence Company Profile Acknowledgement PPT PPT Presentation Reports Brochures One Page Pitch Interview PPT All Categories Powerpoint Templates and Google slides for Forklift TrainingSave your time and attract your audience with our fully editable ppt templates and slides..  Give your next presentation a sophisticated, yet modern look with this 100 percent editable General forklift training colored icon in powerpoint pptx png and editable eps format. Choose from a variety of customizable formats such as PPTx, png, eps. You can use these icons for your presentations, banners, templates, One-pagers that suit your business needs.  Make your presentation profoundly eye-catching leveraging our easily customizable General forklift training monotone icon in powerpoint pptx png and editable eps format. It is designed to draw the attention of your audience. Available in all editable formats, including PPTx, png, and eps, you can tweak it to deliver your message with ease.  The following slide displays timeline for safety training , the provided table highlights the types of risk in the workplace, duration of the training , beginning and end date. Presenting this set of slides with name Specific Safety Training Program General Forklift Ppt Powerpoint Presentation Gallery Templates. The topics discussed in these slides are Training, Checklist, Action Plan, Communication Plan, Duration. This is a completely editable PowerPoint presentation and is available for immediate download. Download now and impress your audience.   Safety TrainingHr compliance training. - Soft Skills Training

- OSHA Required Training

Search By IndustryCourse packages. - Accident Investigation

- Active Shooter

- Air Quality

- Asbestos Awareness

- Back Safety

- Compressed Gas

- Confined Spaces

- Driving Safety

- Electrical Safety

- Emergency Plans

- Ergonomic Safety

- Fall Protection

- Fire Safety

- General Environment

- Hand Safety

- Hazardous Spill

- HazMat Labeling

- Hearing Safety

- Heat Stress

- Housekeeping

- Janitorial Safety

- Jobsite Security

- Ladder Safety

- Lead Safety

- Machine Guarding

- Manufacturing

- Materials Handling

- Office Safety

- Office Security

- Orientation

- Power Tool Safety

- Recordkeeping

- Respiratory Protection

- Rigging Safety

- Safety Audits

- Scaffolding Safety

- Slips, Trips and Falls

- Trenching And Shoring

- Wellness & Fitness

- Winter Safety

- Compensation Training

- Compliance Training

- Conflict Resolution

- Discrimination

- Drugs and Alcohol

- Incident Investigation

- Sexual Harassment

- Supervisor Training

- Workplace Harassment

- Workplace Stress

- Workplace Violence

- Agriculture

- Aviation & Aerospace

- Building Materials

- Ceramics & Concrete

- Construction

- Defense & Space

- Environmental Services

- Facilities Services

- Freight Delivery

- General Health & Safety

- Government Administration

- Human Resources

- Law Enforcement

- Logistics & Supply Chain

- Medical Devices

- Mining & Metals

- Oil and Energy

- Packaging & Containers

- PR & Communications

- Public Works

- Renewables & Environment

- Retail Industry

- School Safety

- Warehousing

- OSHA 10 Construction

- OSHA 30 Construction

- OSHA Top 10 Citations

- Human Resources Compliance

- Warehouse and Manufacturing

- Commercial Driving

- Manager/Supervisor

- Maintenance

- Training Courses

- Customized Training

- Reseller Program

- Safety Tips

- How To Videos

- Safety Toolbox

- Get Our Newsletter

- Submit A Support Ticket

- Schedule A Webinar

- Meet With Tech Support

- Schedule Onsite Training

- Give Us A Call

Home » Training Powerpoints » Forklift Training Powerpoints November 21, 2013 Forklift Training Powerpoints - Turn Down the Volume: Why Your Ears Deserve a Break, Even in the Breakroom - April 29, 2024

- 10 Safety Precautions When Working With Electricity - April 26, 2024

- How the New Overtime Rule Affects You and What to Do to Stay Compliant - April 25, 2024

Safe Operation of Forklift by WSHC Forklift Operator Safety Training by Colby  Forklift Operator Safety by HI Forklifts are a heavy piece of industrial equipment that require proper operation, maintenance, and safety measures. Whether it’s a warehouse forklift or construction forklift, the environment in which a forklift is operating in must also uphold safety measures so that no one is injured. These forklift training PowerPoints aim to break down all the facets of operating a forklift so that it can be performed safely and properly. DISCLAIMER: All free PowerPoints provided on this website have been created by third parties. The copyright owners of these powerpoint presentations have no affiliation with Atlantic Training. If you wish to have an item removed or have any questions regarding this information, please contact us at [email protected] Related Courses  Forklift Operator TrainingDec 21, 2019 1.72k likes | 2.69k Views Forklift Operator Training. Powered Industrial Truck - Definition. A mobile, power-propelled truck used to carry, push, pull, lift, stack or tier materials (American Society of Mechanical Engineers [ASME] definition). Excluded are vehicles used for earth moving and over-the-road hauling. Share Presentation Presentation TranscriptPowered Industrial Truck - Definition • A mobile, power-propelled truck used to carry, push, pull, lift, stack or tier materials (American Society of Mechanical Engineers [ASME] definition). • Excluded are vehicles used for earth moving and over-the-road hauling. • Commonly known as forklifts, pallet trucks, rider trucks, forktrucks, or lift trucks. • Can be powered through electric or combustion engines. Forklifts Are Used Everywhere! • Warehouses • Manufacturing Plants • Construction Sites • Loading Docks • Shipping and Receiving Industries Where Powered Industrial Truck Accidents Occurred Source: OSHA Fatality/Catastrophe Reports, complied by OSHA Office of Electrical/Electronic and Mechanical Engineering Safety Standards. OSHA Requires Trained Competent Operators on Forklifts • All Forklift Operators must be trained and certified by their employer prior to operating forklifts. The certification shall include the name of the operator, the date of the training, the date of the evaluation, and the identity of the person(s) performing the training or evaluation. • Classroom training must cover principles of forklift operation with a hazards and controls review. • Operators must also have their skills tested through a Skills Evaluation. Prevent Forklift Accidents Learn to Operate Safely! What Does It Take To Be Safe? • You • Your Vehicle • Your Attitude You • Be prepared: • Physically • Mentally Your Vehicle - “Condition” • Inspections • Preventive maintenance • Reporting noted items and assuring they are corrected • Application - right for environment Your Attitude Your Attitude or Approach: Safe Behavior Fatalities Resulting from Forklift Accidents • Once every three days in the U.S. • This is in addition to about 95,000 other injuries caused by forklifts every year. • OSHA calculates that about 70% of these accidents could be avoided with proper safety training. Forklift Fatalities by Age Group Source: Bureau of Labor Statistics Non-Fatal Occupational Injuries and Illnesses by Source Source: Bureau of Labor Statistics, Job Related Fatalities by Selected Characteristics, 1996. Goals and Objectives • Goal – To reduce the number of critical behaviors and conditions which occur while operating forklifts: • Discuss principles of forklift operation including how to complete a forklift inspection. • Review capacity plate use and try sample problems. • Review OSHA safe operating requirements. • Evaluate the Job Safety Analysis for forklift operators including pre-lift, lift & move, and set down procedures. • Complete a test to evaluate knowledge. Forklift Use Starts with Inspection • Daily Operator Checklist to be completed prior to first use Check hoses and Cylinders Check Fuel Sources Check all controls Check Brakes Check Steering Capacity Plate • Pick a tire and Walk Around • Check Tires for damage • Check for leaks • Check hoses and cylinders & Fuel Source • Check Lights • Check for Load Chart & Extinguishers • Get Into Forklift • Check Controls and Brakes • Check Lights • Check Gauges Check under engine and lift device for leaks Check Tires Rims and Lug nuts • Fasten Seatbelt and Work! Types of Forklifts • Configurations – Stand, Sit, Walk, Ride • Fuel Types – Electric, Gasoline, Diesel, Propane. • Tire Type – Pneumatic or Hard • Terrain – 4 x 4 Rough Terrain, Warehouse Only, etc. • Powered Pallet Jacks Specialized Attachments • Others Classes of Commonly Used Powered Industrial Trucks • The Industrial Truck Association has placed powered industrial trucks into 7 classes. • Class I - Electric motor rider trucks • Class II - Electric motor narrow aisle trucks • Class III - Electric motor hand trucks or hand/rider trucks • Class IV - Internal combustion engine trucks (solid/cushion tires) • Class V - Internal combustion engine trucks (pneumatic tires) • Class VI - Electric and internal combustion engine tractors • Class VII - Rough terrain forklift trucks * Note that this classification refers to commonly-used vehicles and does not include all powered industrial trucks covered by the OSHA standard. Forklift Designs and Uses • The two front wheels and the center of the rear axle form a STABILITY TRIANGLE. • The center of gravity must remain inside the triangle or the lift truck will tip. • The higher the load, the smaller the triangle gets and the easier it is to tip. Triangle with High Mast Center of Gravity (COG) • The faster you go, the more the center of gravity travels, getting closer to the triangle edge, making it easier to tip. Capacity Plates and Lift Limits • All lift trucks must have a capacity plate. Mast height from floor to forks • Usually require three items to determine capacity: • Load Weight • Load Center • Height of Lift (mast height) LOAD • Always use next lower capacity if load falls between two. Load center – Backrest to Balance point of load • Load center is measured from backrest of forklift. Car vs. Forklift - Differences • Size • Traction • Weight added • Suspension • Moving center of gravity • Rear wheel steering • Forks protruding Stability Triangle Vehicle Center of Gravity (Unloaded) B A Center of Gravity of Vehicle and Maximum Load (Theoretical) C Notes: 1. When the vehicle is loaded, the combined center of gravity (CG) shifts toward line B-C. Theoretically the maximum load will result in the CG at the line B-C. In actual practice, the combined CG should never be at line B-C. 2. The addition of additional counterweight will cause the truck CG to shift toward point A and result in a truck that is less stable laterally. Stability Triangle Load CG Load CG Vertical Stability Line (Line of Action) Combined CG Combined CG Vertical Stability Line (Line of Action) Truck CG Truck CG This vehicle is unstable and will continue to tip over The vehicle is stable Stability Triangle/Capacity Plate Stability Triangle/Counter Weights Stability Triangle Determining the Weight • Shipping Documentation • On the item or on the product (a pallet of 100 50# bags of concrete for instance) • From Weight & Measure Standards: • Wood – by foot for dimensional lumber, wet or dry, wood type • Steel – by for for structural, by square foot for plate, sheet, etc. • Others • Little Black Book of Standards Weights (lbs. for 1x12x12 inches) • Steel= 40.8384 • 1100 Aluminum= 14.1382 • 300 SS= 42.0635 • Copper= 46.7191 • Lead= 59.1340 • Gold= 100.7074 Inch Pound Equation Example Inch Pound Equation (Cont’d) • You operate a lift truck that is rated at 5000 lb @ 24 inch LC. • You must lift a load with an LC of 36 inches. The distance from the center of the front wheels to the face of the forks is 18 inches. • What is the maximum weight you can lift? Inch Pound Equation (Cont’d) To solve the problem, you must break it into two steps: Step 1: You must determine the maximum Inch Pound capacity of the truck. To do this, you must use the equation - (A + B) x C = Inch Pound, where A = 18”, B=24”, and C = 5000 lb. A B Inch Pound Equation (Cont’d) (18” + 24”) x 5000 lb = Inch Pounds (42”) x 5000 = 210,000 Inch Pounds NOTE: The distance from the fulcrum to the face of the forks will vary depending on the size of your truck and the attachments installed. Inch Pound Equation (Cont’d.) To determine the (A) dimension for your truck, measure the distance from the center of the front wheels to the front face of the fork. Inch Pound Equation (Cont’d.) Inch Pound Equation (Cont’d.) Step 2: Once you have determined the maximum Inch Pound capacity of the truck, you must now determine a new lift capacity for the truck using a Load Center of 36” instead of 24”. Again, you need the equation: (A + B) x C = Inch Pounds. Inch Pound Equation (Cont’d.) Where A = 18”, B = 36”, C = ? Lb. and Inch Pounds = 210,000 (18” + 36”) x ? = 210,000 I.P. (54”) x ? Lb. = 210,000 I.P. Inch Pound Equation (Cont’d.) To determine the new capacity, divide 210,000 Inch Pounds by 54”. ? Lb = 210,000 Inch Pounds /54” The lift capacity at a 36 inch load center is 3,888 lb. Safe Operating Rules and Practices • OSHA Rules • Job Hazard Analysis Rules • Rules of refueling gas • Rules for recharging batteries • Rules for refueling propane Ensuring a Safe Ride • Only YOU the operator can ensure the forklift is operated safely. • Conduct a pre-check. • Know your route of travel. • Don’t use un-safe equipment. Pre-check • Conduct a safety check at the start of each day or the first time you use the equipment for the day. • The checklist ensures YOUR safety. Pre-shift Inspections As stated in OSHA Regulations “Industrial trucks shall be examined before being placed in service, and shall not be placed in service if the examination shows any condition adversely affecting the safety of the vehicle. Such examination shall be made at least daily.” Pre-shift Inspections (Cont’d.) OSHA has made it quite clear that these inspections are to be carried out on a regular basis. Keep in mind that the only way to prove that these inspections are being done is to record them. Pre-shift Inspections (Cont’d.) Pre-shift Inspections (Cont’d.) It is highly recommended that the operator fill out a pre-shift inspection form to be retained by the company as proof that this regulation is being complied with at the site. Parts Know your equipment: • Controls • Adjustments • Load Rating • Overhead clearance • Side Clearance Parts *One of the most common types of powered industrial trucks  Forklift Operator Training . 29 CFR 1910.178. Is Forklift Training Necessary?. About 100 deaths each year About 95,000 accidents each year Bankruptcy New OSHA training standard. Forklift Operating Goals. Hazards and forklift stability Inspecting and operating a forklift Quiz. 669 views • 31 slides  FORKLIFT OPERATOR QUALIFICATION PROGRAMFORKLIFT OPERATOR QUALIFICATION PROGRAM. Objectives of this course. To become qualified to operate a forklift (aka forktruck or Powered Industrial Truck) Learn the rules for safe operation How to avoid forktruck accidents How to prevent high maintenance cost 1.2k views • 71 slides  Forklift Operator Training OSHA 1910.178 Powered Industrial TrucksForklift Operator Training OSHA 1910.178 Powered Industrial Trucks. Developed by HMTRI through cooperative agreement # 2 U45 ES006177-14 with NIEHS under the Worker Safety and Health Training Support Annex. Objectives of this training - At the end of this session, you should be able to:. 976 views • 61 slides  Forklift Training Toronto - CN ForkliftCN fork Lift Training Center provides training and certification programs. Get forklift license from professional trainer in Ontario. 155 views • 6 slides  Forklift Operator Training and Forklift Certification in Ottawa, ON CanadaAre you looking for Forklift Training And Certification In Ottawa, Canada then don’t search more when this company is serving similar services at affordable service prices. The ProSAP Forklift And Equipment Training Company can serve you the similar services of forklift training easily. Professionalism will be the constant term that you will see in the services of this mentioned company. 83 views • 6 slides  Forklift Training SydneyForklift is a high power vehicle as compared to the rest of driving vehicles, there are more risks associated with such kind of high power operating vehicles. That's why Forklift Training Sydney trained candidate to operate such vehicles. https://bit.ly/2UEmVTe 92 views • 4 slides  Forklift Training - GeneralForklift Training - General. Overview. Only trained and evaluated operators can drive forklifts Employer certifies successful completion of training and evaluation. 1a. Overview. Operators can only drive the types of forklifts on which they have been trained. 1b. Overview. 598 views • 49 slides  Forklift Operator SafetyForklift Operator Safety. The Importance of Safety. NIOSH calculates that approximately 100 deaths and 20,000 injuries occur annually in the U.S. due to forklifts. The costs incurred by forklift related accidents are estimated to be over $100,000,000. 366 views • 27 slides  315 views • 27 slides  674 views • 61 slides  OPERATOR TRAININGOPERATOR TRAINING. Calhoun Energy Center Title V Air Permit - 40 CFR 75 April 2014. COURSE OUTLINE. Review Air Permit Requirements Production Execution Requirements Daily On-line Weekly Quarterly Maintenance Documentation ERTS Appendix D - Fuel Flow Requirements. 878 views • 44 slides  FORKLIFT OPERATOR SAFETY TRAININGFORKLIFT OPERATOR SAFETY TRAINING. Objectives. Understand the unique hazards of forklift operation Specifics of Colby’s forklift (PIT) Safe movement during picking, stacking and traveling with loads Preuse inspections. Top 10 Forklift Accidents. Forklift Operator Training. 926 views • 47 slides  Forklift TrainingForklift Training. Forklift Fatalities by Age Group 1992 -1996. There are about 100 fatalities each year related to forklifts. Source: Bureau of Labor Statistics. Content. What is a Powered Industrial Truck? Basic Engineering Principles Safe Operating Procedures 1.1k views • 47 slides  Forklift Operator Training. 29 CFR 1910.178. Is Forklift Training Necessary?. About 100 deaths each year About 95,000 accidents each year Bankruptcy New OSHA training standard. Forklift Operating Goals. Hazards and forklift stability Inspecting and operating a forklift Quiz. 476 views • 31 slides  545 views • 49 slides  Online Forklift Training California - Superior Forklift TrainingIf you want to know about the detailed controls of each and every type of forklift machine, then it is better to enrol yourself in a forklift training course. This is because these days all the companies are looking for forklift certified employees. 36 views • 1 slides  NKS Forklift - Forklift Training in CalgaryNKS Forklift is an approved and experienced Forklift Equipment and Safety Training provider company located in NE (North East) Calgary. Our company provides a complete forklift training and certification program for people who wish to learn and then earn. Our forklift training programs are compliant with the Occupational Health and Safety Administration (OHSA). We are training people and making them skilled forklift operators since 2014. This program will make you ready to operate all types of industrial forklift equipment. NKS Forklift training and certification also emphasizes high safety standards important for reducing workplace injuries. Our training and certification programs are in compliance with WCB (Workers Compensation Board) and CSA (Canadian Standard Association). A certificate is provided to every trainee after completion of the training program. Forklift training pricing is provided on demand to the trainees. 78 views • 5 slides  Forklift Training CA – Superior Forklift TrainingTo get the Forklift Training CA, Superior Forklift Training is an ideal option. From here, you will get best services with reasonable price. We have different plans are available. To know more about us, go through this presentation. Get more details about it, Call Now! 866-992-7774 Website: https://www.superiorforklifttraining.com/ 105 views • 5 slides  Best Forklift operator Certification in TorontoCN lift Safety provides the Best Forklift operator Certification in Toronto; we provide the best training to match the safety standards and without a certificate and license, you cannot join any factory as a forklift operator. if you want get more information, than visit our website. 85 views • 7 slides  Forklift Operator Safety Training ProgramsFind the best Forklift Operator Safety Training course for workers? At Safetyfirsttraining.ca, you will get high class forklift operator safety training for your general awareness on the vehicle. Contact us for further information! 77 views • 1 slides  Best License For Forklift Operator CAhttps://www.superiorforklifttraining.com/ 64 views • 5 slides   Forklift Safety - PowerPoint PPT Presentation Forklift SafetyIndustrial, commercial, & construction forklift training – powerpoint ppt presentation. - 1910.178 (l)

- 1915.120 (a)

- 1917.1 (a)(2)(xiv)

- 1918.1 (b)(10)

- 1926.602 (d)

- This presentation is intended as a resource for providing training on OSHAs revised powered industrial truck operator standards. It is not a substitute for any of the provisions of the Occupational Safety and Health Act of 1970, or for any standards issued by the U.S. Department of Labors Occupational Safety and Health Administration (OSHA). It is also not a substitute for a powered industrial truck operator training program.

- OSHAs Office of Training and Education wishes to acknowledge the following for contributing some of the graphics used in this presentation

- Caterpillar Lift Trucks

- Mason Contractors Association of America

- Industrial Truck Association

- State of Utah Labor Commission - Occupational Safety Health Division

- Steamship Trade Association of Baltimore

- Taylor Machine Works, Inc.

- UAW - Ford National Joint Committee on Health and Safety

- Appearance of products does not imply endorsement by the U.S. Department of Labor.

- A mobile, power-propelled truck used to carry, push, pull, lift, stack or tier materials. American Society of Mechanical Engineers (ASME) definition

- Excluded are vehicles used for earth moving and over-the-road hauling.

- Commonly known as forklifts, pallet trucks, rider trucks, forktrucks, or lifttrucks.

- Can be powered through electric or combustion engines.

- The scope provisions of 1910.178(a), which are based on ANSI B56.1 - 1969, remain in effect and cover

- ... fork trucks, tractors, platform lift trucks, motorized hand trucks, and other specialized industrial trucks powered by electric motors or internal combustion engines.

- It does not apply to compressed air or nonflammable compressed gas-operated industrial trucks, farm vehicles, nor vehicles intended primarily for earth moving or over-the-road hauling.

- This scope covers general industry, construction and shipyards.

- For marine terminal and longshoring industries, all powered industrial trucks are covered, no matter what specialized name they are given.

- This includes, but is not limited to, straddle carriers, hustlers, toploaders, container reach stackers, and other vehicles that carry, push, pull, lift, or tier loads.

- Powered industrial truck accidents cause approximately 100 fatalities and 36,340 serious injuries in general industry and construction annually.

- It is estimated that 20 - 25 of the accidents are, at least in part, caused by inadequate training.

- Updated consensus standards have been published.

- OSHA has been petitioned to improve the requirements for industrial truck training.

- Advisory Committee on Construction Safety and Health has recommended improving the standard.

- Resolutions have been introduced in the Senate and House urging OSHA to revise its outdated standard.

- The previous OSHA standards, while requiring operator training, did not define the type of training or authorization required.

- March 15, 1988 - Industrial Truck Association (ITA) petitioned OSHA for specific training requirements.

- American National Standards Institute (ANSI), in cooperation with ASME, has revised its standard 4 times, including current lifttruck technology and specific training topics.

- OSHA published a proposed ruling on March 14, 1995 for General Industry, Shipyard, Marine Terminals, and Longshoring regulations, adding specific training requirements.

- On January 30, 1996, OSHA proposed a revision of the construction standards, mandating the development of an operator training program based on the prior knowledge and skills of the trainee and requiring a periodic evaluation.

- OSHA published the final rule for Powered Industrial Truck Operator Training on December 1, 1998.

- The effective date is March 1, 1999. Start-up dates are included in paragraph (l)(7).

- It applies to all industries except agricultural operations.

- OSHA estimates that the new rule will prevent 11 deaths and 9,422 injuries per year.

- The powered industrial truck operator training requirements are performance-oriented to permit employers to tailor a training program to the characteristics of their workplaces and the particular types of powered industrial trucks operated.

- General Industry 1910.178 is amended by revising paragraph (l) and adding Appendix A.

- Shipyard Employment New section 1915.120 and Appendix A are added.

- Marine Terminals Section 1917.1 is amended by adding new paragraph (a)(2)(xiv) and Appendix A.

- Longshoring Section 1918.1 is amended by adding new paragraph (b)(10) and Appendix A.

- Construction 1926.602 is amended by adding new paragraph (d) and Appendix A.

- Safe operations

- The employer shall ensure that each powered industrial truck operator is competent to operate a powered industrial truck safely, as demonstrated by successful completion of the training and evaluation specified in the OSHA standard.

- Prior to permitting an employee to operate a powered industrial truck (except for training purposes), the employer shall ensure that each operator has successfully completed the required training (or previously received appropriate training).

- Trainees may operate a powered industrial truck only

- Under direct supervision of a person who has the knowledge, training, and experience to train operators and evaluate their competence and,

- Where such operation does not endanger the trainee or other employees.

- Training shall consist of a combination of

- Formal instruction (e.g., lecture, discussion, interactive computer learning, written material),

- Practical training (demonstrations and exercises performed by the trainee), and

- Evaluation of the operators performance in the workplace

- Training and evaluation shall be conducted by a person with the knowledge, training and experience to train powered industrial truck operators and evaluate their competence.

- Operators shall receive initial training in the following topics, except in topics which the employer can demonstrate are not applicable to safe operation in the employers workplace.

- Truck-related topics

- Workplace-related topics

- The requirements of the standard

- Operating instructions, warnings and precautions

- Differences from automobile

- Controls and instrumentation

- Engine or motor operation

- Steering and maneuvering

- Fork and attachment adaptation, operation, use

- Vehicle capacity and stability

- Vehicle inspection and maintenance that the operator will be required to perform

- Refueling/Charging/ Recharging batteries

- Operating limitations

- Other instructions, etc.

- Surface conditions

- Composition and stability of loads

- Load manipulation, stacking, unstacking

- Pedestrian traffic

- Narrow aisles and restricted areas

- Operating in hazardous (classified) locations

- Operating on ramps and sloped surfaces

- Potentially hazardous environmental conditions

- Operating in closed environments or other areas where poor ventilation or maintenance could cause carbon monoxide or diesel exhaust buildup

- The requirements of the OSHA standard on powered industrial trucks must also be included in the initial operator training program.

- Refresher training, including an evaluation of the effectiveness of that training, shall be conducted to ensure that the operator has the knowledge and skills needed to operate the powered industrial truck safely.

- Refresher training required when

- Unsafe operation

- Accident or near-miss

- Evaluation indicates need

- Different type of equipment introduced

- Workplace condition changes

- An evaluation of each powered industrial truck operators performance must be conducted

- After initial training,

- After refresher training, and

- At least once every three years

- If an operator has previously received training in a topic specified in this section, and the training is appropriate to the truck and working conditions encountered, additional training in that topic is not required if the operator has been evaluated and found competent to operate the truck safely.

- The employer shall certify that each operator has been trained and evaluated as required by the standard.

- Certification shall include

- Name of operator

- Date of training

- Date of evaluation

- Identity of person(s) performing the training or evaluation

- The employer shall ensure that operators of powered industrial trucks are trained, as appropriate, by the dates shown in the following table.

- Appendix A provides non-mandatory guidance to assist employers in implementing the standard.

- This appendix does not add to, alter, or reduce the requirements of this section.

- Definitions

- Basic Principles

- Stability Triangle

- Longitudinal Stability

- Lateral Stability

- Dynamic Stability

- Four major areas of concern must be addressed

- The general hazards that apply to the operation of all or most powered industrial trucks

- The hazards associated with the operation of particular types of trucks

- The hazards of workplaces generally and,

- The hazards of the particular workplace where the vehicle operates.

- There are many different types of powered industrial trucks covered by the OSHA standard.

- Commonly used types include

- High lift trucks, counterbalanced trucks, cantilever trucks, rider trucks, forklift trucks, high lift trucks, high lift platform trucks, low lift trucks, motorized hand trucks, pallet trucks, straddle trucks, reach rider trucks, high lift order picker trucks, motorized hand/rider trucks, and counterbalanced front/side loader lift trucks.

- A single type of truck can only be described by calling it by all of its characteristics, (e.g., a high lift, counterbalanced, sit down rider truck).

- Each type of powered industrial truck has its own unique characteristics and some inherent hazards.

- To be effective, training must address the unique characteristics of the type of vehicle the employee is being trained to operate.

- The Industrial Truck Association has placed powered industrial trucks into 7 classes.

- Class I - Electric motor rider trucks

- Class II - Electric motor narrow aisle trucks

- Class III - Electric motor hand trucks or hand/rider trucks

- Class IV - Internal combustion engine trucks (solid/cushion tires)

- Class V - Internal combustion engine trucks (pneumatic tires)

- Class VI - Electric and internal combustion engine tractors

- Class VII - Rough terrain forklift trucks

- Counterbalanced rider type, stand up

- Three wheel electric trucks, sit-down

- Counterbalanced rider type, cushion tires, sit-down (high and low platform)

- Counterbalanced rider, pneumatic tire, sit-down (high and low platform)

- Counterbalanced Rider Type, Stand-Up

- High lift straddle

- Order picker

- Reach type outrigger

- Side loaders, turret trucks, swing mast and convertible turret/stock pickers

- Low lift pallet and platform (rider)

- Low lift platform

- Low lift walkie pallet

- High lift counterbalanced

- Low lift walkie/rider pallet

- Straight-mast forklift

- Extended-reach forklift

- The following types of vehicles are covered by the OSHA standard if the vehicles carry, push, pull, lift, or tier loads.

- Container top handlers

- Container reach stackers

- Straddle carriers

- Semi-tractors/ Utility vehicles

- Sidehandlers

- Combination vacuum lifts

- Yard tractors

PowerShow.com is a leading presentation sharing website. It has millions of presentations already uploaded and available with 1,000s more being uploaded by its users every day. Whatever your area of interest, here you’ll be able to find and view presentations you’ll love and possibly download. And, best of all, it is completely free and easy to use. You might even have a presentation you’d like to share with others. If so, just upload it to PowerShow.com. We’ll convert it to an HTML5 slideshow that includes all the media types you’ve already added: audio, video, music, pictures, animations and transition effects. Then you can share it with your target audience as well as PowerShow.com’s millions of monthly visitors. And, again, it’s all free. About the Developers PowerShow.com is brought to you by CrystalGraphics , the award-winning developer and market-leading publisher of rich-media enhancement products for presentations. Our product offerings include millions of PowerPoint templates, diagrams, animated 3D characters and more.   |

COMMENTS

Training Certificate - Forklift Operator This a is a sample training certificate that can be used for your training presentations. 49 slides: Forklift Training - General General safety awareness for the operation of forklifts. About 1/3 of all transport related accidents involve lift trucks. Construction and Mining Equipment PowerPoint Resources

Washington L&I Forklift Safety PowerPoint. This presentation covers all types of forklifts and gives a good overview of the basics of forklift safety. Slides: 61. Author: Washington State Department of Labor & Industries. includes everything instructors need to know about training and certifying forklift operators.

By converting your existing forklift training PowerPoint presentations into microlearning courses, you also promote on-the-go learning that integrates training into their busy schedules. SC Training (formerly EdApp) also offers ready-made courses specifically designed for forklift training. These create an effortless transition from traditional ...

Presentation Transcript. Forklift rules • Use mechanical dock locks or set brakes of highway trucks before driving on trailer. • Follow any special precautions 2h. Forklift Training - General. Overview. Only trained and evaluated operators can drive forklifts Employer certifies successful completion of training and evaluation. 1a. Overview.

Certification Requirements. Every forklift operator needs initial certification good for 3 years. Refresher training is required every 3 years or sooner if the operator has been involved in an accident or near miss. The operator has been observed to be unsafe. Evaluation indicated need for additional training.

PK ! v‹>Ò ¹w [Content_Types].xml ¢ ( Ì ÛnÚ@ †ï+õ o«`|v« \ôpÕC¤¤ à Üú${"6oßÅ@B" ‡™Õ?7QŒ½³Ÿ k ½Ãù忲 Ü«¶ËëjìxÃ'3PÕ¤žæÕíØùyóå,u ΪiVÔ• ; ªs./Þ¾9¿yhT70«nì̵n>¸n7™«2ë†u£*³fV·e¦Íb{ë6ÙäOv«\ 4ŠÝI]iUé3½ˆá\œ R³ì®ÐƒÏÿÌËK'ß ºu — .ú ;y¹ Яpw´9ºISmo²x}{‹V Ý‹&YÓ ù$Óf½{_M_ìþÙj× ...

Forklift Operator Training. An Image/Link below is provided (as is) to download presentation Download Policy: Content on the Website is provided to you AS IS for your information and personal use and may not be sold / licensed / shared on other websites without getting consent from its author. Download presentation by click this link.

Forklift & cargolift Training ppt.pptx - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides guidance on forklift, cargo lift, and emergency safety. It discusses what forklifts and cargo lifts are, types of forklifts, personal protective equipment for forklift operators, forklift and cargo lift ...

1 Forklift Operator Training. 29 CFR I. Background for the Trainer: Your company should have a written Powered Industrial Truck Program. If so, each operator should be issued a copy of the program. Passing it out in the beginning of the class would be a good idea so that you can refer to its contents during the training session.

Make your presentation profoundly eye-catching leveraging our easily customizable General forklift training monotone icon in powerpoint pptx png and editable eps format. It is designed to draw the attention of your audience. Available in all editable formats, including PPTx, png, and eps, you can tweak it to deliver your message with ease.

Forklifts. PowerPoints. Safe Forklift Operation (Spanish) Spanish. National. Safety training resources including PowerPoints, audio presentations, tool box talks, meetings, handouts, and quizzes, all complete with trainer's resources for easy training.

Purpose of This Training Module. You may use this slide presentation to comply with the training requirements of the DOSH forklift regulations (WAC 296-863). You can read the training requirements in the rule at the end of this guide. The topics covered in this module are those required in the rule. However, you may use different materials that ...

47. Created By: Colby. This training powerpoint start out by explaining why training is so important and why it's necessary for forklift operation. It then goes into pre-use inspection. After which, it provides general safe practices associated with forklift operation. It's pretty easy to follow, and covers the different load balance points.

Training Presentation - Forklift Safety - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Forklift operators must be trained and certified. Forklifts differ from cars in that they are heavier, have reduced visibility, use rear-wheel steering, and operate in complex traffic environments.

Forklift Safety Cage Training. Forklift Safety Cage Training. Presented by Tom Dausch. Forklift Safety Cage. This presentation will cover fall protection when using a forklift safety cage. This training is required for all individuals using the safety cage. Training Outline. Topic 1: Attaching the cage to the forklift. 1.05k views • 7 slides

About This Presentation. Title: Forklift Training - General. Description: Forklift Training - General Overview Only trained and evaluated operators can drive forklifts Employer certifies successful completion of training and evaluation ... - PowerPoint PPT presentation. Number of Views: 1076. Avg rating:3.0/5.0.

Toolbox Talks. Forklifts: Tips for safe operations at loading docks. English. National. Safety training resources including PowerPoints, audio presentations, tool box talks, meetings, handouts, and quizzes, all complete with trainer's resources for easy training.

Forklift Operator Training OSHA 1910.178 Powered Industrial Trucks Developed by HMTRI through cooperative agreement # 2 U45 ES006177-14 with NIEHS under the Worker ... - A free PowerPoint PPT presentation (displayed as an HTML5 slide show) on PowerShow.com - id: 424ab4-NGYwY ... The PowerPoint PPT presentation: "Forklift Operator Training ...

Forklift Operator Training. Powered Industrial Truck - Definition • A mobile, power-propelled truck used to carry, push, pull, lift, stack or tier materials (American Society of Mechanical Engineers [ASME] definition). • Excluded are vehicles used for earth moving and over-the-road hauling. • Commonly known as forklifts, pallet trucks ...

4 Tips for Forklift Safety -Forklift Training Brampton - CN Lift Safety provides industrial level competent new Forklift Operator Training and Forklift Refresher Training and Certification. We're the leading providers of Forklift Training in Brampton, Mississauga, and Toronto. | PowerPoint PPT presentation | free to view