- Business & Money

- Management & Leadership

Sorry, there was a problem.

Download the free Kindle app and start reading Kindle books instantly on your smartphone, tablet, or computer - no Kindle device required .

Read instantly on your browser with Kindle for Web.

Using your mobile phone camera - scan the code below and download the Kindle app.

Image Unavailable

- To view this video download Flash Player

Follow the author

Quality Control Problem-Solving Made Easy: An Actionable Workbook: Empower Your Quality Control Efforts with Practical Problem-Solving Approaches Paperback – August 29, 2023

- Print length 130 pages

- Language English

- Publication date August 29, 2023

- Dimensions 8.5 x 0.3 x 11 inches

- ISBN-13 979-8860092549

- See all details

Products related to this item

From the Publisher

Product details

- ASIN : B0CH2QPCT5

- Publisher : Independently published (August 29, 2023)

- Language : English

- Paperback : 130 pages

- ISBN-13 : 979-8860092549

- Item Weight : 14.1 ounces

- Dimensions : 8.5 x 0.3 x 11 inches

- #292 in Industrial Quality Control

- #451 in Total Quality Management (Books)

- #786 in Quality Control (Books)

About the author

Sithila manoj weerasinghe.

Sithila Manoj Weerasinghe, a qualified quality assurance (QA) specialist and a proficient writer with a passion for health, fitness, and wellness. Holding a degree in science, Sithila Manoj Weerasinghe has acquired extensive knowledge and experience in product manufacturing, specializing in quality control and auditing.

As a seasoned QA specialist, Sithila Manoj Weerasinghe has developed a keen eye for detail, ensuring that products meet the highest quality standards. Sithila Manoj Weerasinghe's expertise and dedication to the field have earned them a reputation as a trustworthy and reliable professional.

In their spare time, Sithila Manoj Weerasinghe indulges their love for writing, exploring topics related to health, fitness, and wellness. With a deep interest in holistic living, Sithila Manoj Weerasinghe seeks to inspire and motivate others to adopt healthy lifestyle habits and practices.

Through Sithila Manoj Weerasinghe's engaging and informative writing style, they aim to educate their readers on the latest health trends and tips for maintaining a balanced lifestyle. Whether it's through blogs, articles, or social media content, Sithila Manoj Weerasinghe brings a fresh and unique perspective to the world of wellness writing.

Overall, Sithila Manoj Weerasinghe is a multifaceted individual with a strong work ethic, a passion for quality control, and a writing talent. Their ability to combine their technical knowledge with their creative flair makes them a valuable asset to any team or project they undertake.

He holds a bachelor’s degree in science in Mathematics and Physics.

Customer reviews

- 5 star 4 star 3 star 2 star 1 star 5 star 100% 0% 0% 0% 0% 100%

- 5 star 4 star 3 star 2 star 1 star 4 star 100% 0% 0% 0% 0% 0%

- 5 star 4 star 3 star 2 star 1 star 3 star 100% 0% 0% 0% 0% 0%

- 5 star 4 star 3 star 2 star 1 star 2 star 100% 0% 0% 0% 0% 0%

- 5 star 4 star 3 star 2 star 1 star 1 star 100% 0% 0% 0% 0% 0%

Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them.

To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness.

- Sort reviews by Top reviews Most recent Top reviews

Top reviews from the United States

Top reviews from other countries.

- About Amazon

- Investor Relations

- Amazon Devices

- Amazon Science

- Sell products on Amazon

- Sell on Amazon Business

- Sell apps on Amazon

- Become an Affiliate

- Advertise Your Products

- Self-Publish with Us

- Host an Amazon Hub

- › See More Make Money with Us

- Amazon Business Card

- Shop with Points

- Reload Your Balance

- Amazon Currency Converter

- Amazon and COVID-19

- Your Account

- Your Orders

- Shipping Rates & Policies

- Returns & Replacements

- Manage Your Content and Devices

- Conditions of Use

- Privacy Notice

- Consumer Health Data Privacy Disclosure

- Your Ads Privacy Choices

+91 9282344519

The Qc Problem Solving Approach

₹ 395.00

“The QC Problem Solving Approach” by Katsuya Hosotani provides a practical framework for quality professionals, leveraging real-world cases to achieve continuous improvement.

Description

Additional information, reviews (0).

The QC Problem Solving Approach” by Katsuya Hosotani offers a structured methodology for identifying and resolving quality issues within organizations. Drawing on real-world case studies and practical insights, the book equips readers with the tools and techniques necessary for effective problem-solving and continuous improvement. Essential reading for quality professionals and managers seeking to enhance organizational performance.

| Dimensions | 20.8 × 1 × 13.1 cm |

|---|---|

| ISBN | 9788185984933 |

| Page count | 190 pages |

| Edition | 2024 |

| Binding | Paperback |

| Language | English |

There are no reviews yet.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Related products

Getting Things Done the art of stress free productivity

Kaizen Express

Failure Mode and Effect Analysis

An Introduction to Triz

The 9 Nuggets for Innovation

Username or email *

- All category

- Agriculture

- Autobiography

- Corporate Social Responsibility.

- Environment

- Essays/Memoirs

- Human resource

- Maintenance

- Personal Finance

- Philosophy / Spirituality

- Political science

- Quality control

- Self Improvement

- Supply chain management

- Theory of Constraints

- Total Productivity Maintenance

- Total Quality Management

Eight Disciplines of Problem Solving (8D)

– Eight Disciplines of Problem Solving –

⇓ Introduction to 8D

⇓ What is 8D

⇓ Why Apply 8D

⇓ When to Apply 8D

⇓ How to Apply 8D

Introduction to Eight Disciplines of Problem Solving (8D)

The Eight Disciplines of Problem Solving (8D) is a problem solving methodology designed to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems. When it’s clear that your product is defective or isn’t satisfying your customers, an 8D is an excellent first step to improving Quality and Reliability.

Ford Motor Company developed this problem solving methodology, then known as Team Oriented Problem Solving (TOPS), in the 1980s. The early usage of 8D proved so effective that it was adopted by Ford as the primary method of documenting problem solving efforts, and the company continues to use 8D today.

8D has become very popular among manufacturers because it is effective and reasonably easy to teach. Below you’ll find the benefits of an 8D, when it is appropriate to perform and how it is performed.

What is Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is a detailed, team oriented approach to solving critical problems in the production process. The goals of this method are to find the root cause of a problem, develop containment actions to protect customers and take corrective action to prevent similar problems in the future.

The strength of the 8D process lies in its structure, discipline and methodology. 8D uses a composite methodology, utilizing best practices from various existing approaches. It is a problem solving method that drives systemic change, improving an entire process in order to avoid not only the problem at hand but also other issues that may stem from a systemic failure.

8D has grown to be one of the most popular problem solving methodologies used for Manufacturing, Assembly and Services around the globe. Read on to learn about the reasons why the Eight Disciplines of Problem Solving may be a good fit for your company.

Why Apply Eight Disciplines of Problem Solving (8D)

The 8D methodology is so popular in part because it offers your engineering team a consistent, easy-to-learn and thorough approach to solving whatever problems might arise at various stages in your production process. When properly applied, you can expect the following benefits:

- Improved team oriented problem solving skills rather than reliance on the individual

- Increased familiarity with a structure for problem solving

- Creation and expansion of a database of past failures and lessons learned to prevent problems in the future

- Better understanding of how to use basic statistical tools required for problem solving

- Improved effectiveness and efficiency at problem solving

- A practical understanding of Root Cause Analysis (RCA)

- Problem solving effort may be adopted into the processes and methods of the organization

- Improved skills for implementing corrective action

- Better ability to identify necessary systemic changes and subsequent inputs for change

- More candid and open communication in problem solving discussion, increasing effectiveness

- An improvement in management’s understanding of problems and problem resolution

8D was created to represent the best practices in problem solving. When performed correctly, this methodology not only improves the Quality and Reliability of your products but also prepares your engineering team for future problems.

When to Apply Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is typically required when:

- Safety or Regulatory issues has been discovered

- Customer complaints are received

- Warranty Concerns have indicated greater-than-expected failure rates

- Internal rejects, waste, scrap, poor performance or test failures are present at unacceptable levels

How to Apply Eight Disciplines of Problem Solving (8D)

The 8D process alternates inductive and deductive problem solving tools to relentlessly move forward toward a solution. The Quality-One approach uses a core team of three individuals for inductive activities with data driven tools and then a larger Subject Matter Expert (SME) group for the deductive activities through brainstorming, data-gathering and experimentation.

D0: Prepare and Plan for the 8D

Proper planning will always translate to a better start. Thus, before 8D analysis begins, it is always a good idea to ask an expert first for their impressions. After receiving feedback, the following criterion should be applied prior to forming a team:

Collect information on the symptoms

Use a Symptoms Checklist to ask the correct questions

Identify the need for an Emergency Response Action (ERA), which protects the customer from further exposure to the undesired symptoms

D1: Form a Team

A Cross Functional Team (CFT) is made up of members from many disciplines. Quality-One takes this principle one step further by having two levels of CFT:

- The Core Team Structure should involve three people on the respective subjects: product, process and data

- Additional Subject Matter Experts are brought in at various times to assist with brainstorming, data collection and analysis

Teams require proper preparation. Setting the ground rules is paramount. Implementation of disciplines like checklists, forms and techniques will ensure steady progress. 8D must always have two key members: a Leader and a Champion / Sponsor:

- The Leader is the person who knows the 8D process and can lead the team through it (although not always the most knowledgeable about the problem being studied)

- The Champion or Sponsor is the one person who can affect change by agreeing with the findings and can provide final approval on such changes

D2: Describe the Problem

The 8D method’s initial focus is to properly describe the problem utilizing the known data and placing it into specific categories for future comparisons. The “Is” data supports the facts whereas the “Is Not” data does not. As the “Is Not” data is collected, many possible reasons for failure are able to be eliminated. This approach utilizes the following tools:

- Problem Statement

- Affinity Diagram (Deductive tool)

- Fishbone/Ishikawa Diagram (Deductive tool)

- Problem Description

D3: Interim Containment Action

In the interim, before the permanent corrective action has been determined, an action to protect the customer can be taken. The Interim Containment Action (ICA) is temporary and is typically removed after the Permanent Correct Action (PCA) is taken.

- Verification of effectiveness of the ICA is always recommended to prevent any additional customer dissatisfaction calls

D4: Root Cause Analysis (RCA) and Escape Point

The root cause must be identified to take permanent action to eliminate it. The root cause definition requires that it can be turned on or off, at will. Activities in D4 include:

- Comparative Analysis listing differences and changes between “Is” and “Is Not”

- Development of Root Cause Theories based on remaining items

- Verification of the Root Cause through data collection

- Review Process Flow Diagram for location of the root cause

- Determine Escape Point, which is the closest point in the process where the root cause could have been found but was not

D5: Permanent Corrective Action (PCA)

The PCA is directed toward the root cause and removes / changes the conditions of the product or process that was responsible for the problem. Activities in D5 include:

- Establish the Acceptance Criteria which include Mandatory Requirements and Wants

- Perform a Risk Assessment / Failure Mode and Effects Analysis (FMEA) on the PCA choices

- Based on risk assessment, make a balanced choice for PCA

- Select control-point improvement for the Escape Point

- Verification of Effectiveness for both the PCA and the Escape Point are required

D6: Implement and Validate the Permanent Corrective Action

To successfully implement a permanent change, proper planning is essential. A project plan should encompass: communication, steps to complete, measurement of success and lessons learned. Activities in D6 include:

- Develop Project Plan for Implementation

- Communicate the plan to all stakeholders

- Validation of improvements using measurement

D7: Prevent Recurrence

D7 affords the opportunity to preserve and share the knowledge, preventing problems on similar products, processes, locations or families. Updating documents and procedures / work instructions are expected at this step to improve future use. Activities in D7 include:

- Review Similar Products and Processes for problem prevention

- Develop / Update Procedures and Work Instructions for Systems Prevention

- Capture Standard Work / Practice and reuse

- Assure FMEA updates have been completed

- Assure Control Plans have been updated

D8: Closure and Team Celebration

Teams require feedback to allow for satisfactory closure. Recognizing both team and individual efforts and allowing the team to see the previous and new state solidifies the value of the 8D process. Activities in D8 include:

- Archive the 8D Documents for future reference

- Document Lessons Learned on how to make problem solving better

- Before and After Comparison of issue

- Celebrate Successful Completion

8D and Root Cause Analysis (RCA)

The 8D process has Root Cause Analysis (RCA) imbedded within it. All problem solving techniques include RCA within their structure. The steps and techniques within 8D which correspond to Root Cause Analysis are as follows:

- Problem Symptom is quantified and converted to “Object and Defect”

- Problem Symptom is converted to Problem Statement using Repeated Whys

- Possible and Potential Causes are collected using deductive tools (i.e. Fishbone or Affinity Diagram)

- Problem Statement is converted into Problem Description using Is / Is Not

- Problem Description reduces the number of items on the deductive tool (from step 3)

- Comparative Analysis between the Is and Is Not items (note changes and time)

- Root Cause theories are developed from remaining possible causes on deductive tool and coupled with changes from Is / Is Not

- Compare theories with current data and develop experiments for Root Cause Verification

- Test and confirm the Root Causes

Example: Multiple Why Technique

The Multiple / Repeated Why (Similar to 5 Why) is an inductive tool, which means facts are required to proceed to a more detailed level. The steps required to determine problem statement are:

- Problem Symptom is defined as an Object and Defect i.e. “Passenger Injury”

- Why? In every case “SUV’s Roll Over”

- Why? In every case, it was preceded by a “Blown Tire”

- Why? Many explanations may be applied, therefore the team cannot continue with another repeated why past “Blown Tire”

- Therefore, the Problem Statement is “Blown Tire”

- Why? Low (Air) Pressure, Tire Defect (Degradation of an Interface) and High (Ambient) Temperature

- Counter measures assigned to low pressure and tire defect

This example uses only 4 of the 5 Whys to determine the root causes without going further into the systemic reasons that supported the failure. The Repeated Why is one way to depict this failure chain. Fault Tree Analysis (FTA) could also be used.

Learn More About Eight Disciplines of Problem Solving (8D)

Quality-One offers Quality and Reliability Support for Product and Process Development through Consulting, Training and Project Support. Quality-One provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires. Let us help you Discover the Value of 8D Consulting , 8D Training or 8D Project Support .

Contact Us | Discover the Value!

(248) 280-4800 | [email protected]

Remember Me

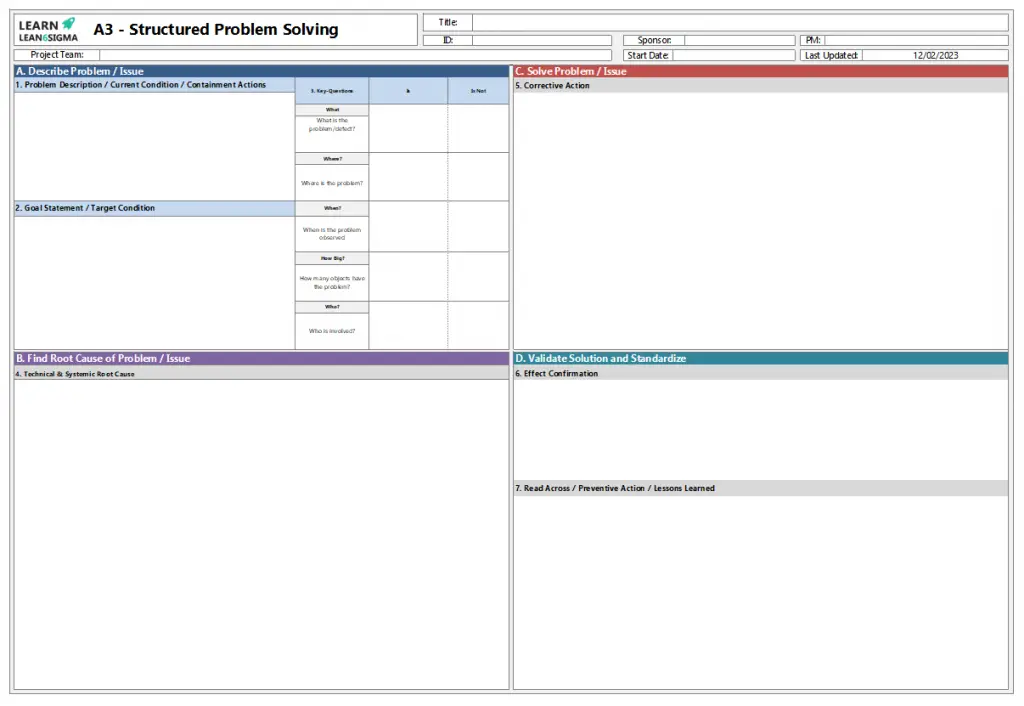

A Step-by-Step Guide to A3 Problem Solving Methodology

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

Problem-solving is an important component of any business or organization. It entails identifying, analyzing, and resolving problems in order to improve processes, drive results, and foster a culture of continuous improvement. A3 Problem solving is one of the most effective problem-solving methodologies.

A3 Problem solving is a structured and systematic approach to problem-solving that originated with the lean manufacturing methodology. It visualizes the problem-solving process using a one-page document known as an A3 report. The A3 report provides an overview of the problem, data analysis, root causes, solutions, and results in a clear and concise manner.

A3 Problem Solving has numerous advantages, including improved communication, better decision-making, increased efficiency, and reduced waste. It is a powerful tool for businesses of all sizes and industries, and it is especially useful for solving complex and multi-faceted problems.

In this blog post, we will walk you through the A3 Problem Solving methodology step by step. Whether you are new to A3 Problem Solving or simply want to improve your skills, this guide will help you understand and apply the process in your workplace.

What is A3 Problem Solving?

A3 Problem Solving is a structured and systematic approach to problem-solving that makes use of a one-page document called an A3 report to visually represent the process. The A3 report provides an overview of the problem, data analysis, root causes, solutions, and results in a clear and concise manner. The method was created within the framework of the Lean manufacturing methodology and is based on the principles of continuous improvement and visual management.

Looking for a A3 Problem solving template? Click here

Origin and History of A3 Problem Solving

A3 Problem Solving was developed by Toyota Motor Corporation and was first used in the manufacture of automobiles. The term “A3” refers to the size of the paper used to create the report, which is an ISO standard known as “A3”. The goal of the A3 report is to provide a visual representation of the problem-solving process that all members of the organisation can easily understand and share. A3 Problem Solving has been adopted by organisations in a variety of industries over the years, and it has become a widely used and recognised method for problem-solving.

Key Principles of A3 Problem Solving

The following are the key principles of A3 Problem Solving:

- Define the problem clearly and concisely

- Gather and analyze data to gain a deep understanding of the problem

- Identify the root causes of the problem

- Develop and implement effective solutions

- Evaluate results and continuously improve

These principles serve as the foundation of the A3 Problem Solving methodology and are intended to assist organisations in continuously improving and achieving their objectives. Organizations can effectively solve problems, identify areas for improvement, and drive results by adhering to these principles.

Step 1: Define the Problem

Importance of clearly defining the problem.

The first step in the A3 Problem Solving process is critical because it lays the groundwork for the remaining steps. To define the problem clearly and accurately, you must first understand the problem and identify the underlying root cause. This step is critical because if the problem is not correctly defined, the rest of the process will be based on incorrect information, and the solution developed may not address the issue effectively.

The significance of defining the problem clearly cannot be overstated. It aids in the collection and analysis of relevant data, which is critical for developing effective solutions. When the problem is clearly defined, the data gathered is more relevant and targeted, resulting in a more comprehensive understanding of the issue. This will enable the development of solutions that are more likely to be effective because they are founded on a thorough and accurate understanding of the problem.

However, if the problem is not clearly defined, the data gathered may be irrelevant or incorrect, resulting in incorrect conclusions and ineffective solutions. Furthermore, the process of collecting and analysing data can become time-consuming and inefficient, resulting in resource waste. Furthermore, if the problem is not accurately defined, the solutions developed may fail to address the root cause of the problem, resulting in ongoing issues and a lack of improvement.

Techniques for Defining the Problem

The first step in the A3 Problem Solving process is to clearly and accurately define the problem. This is an important step because a clearly defined problem will help to ensure that the appropriate data is collected and solutions are developed. If the problem is not clearly defined, incorrect data may be collected, solutions that do not address the root cause of the problem, and time and resources may be wasted.

A problem can be defined using a variety of techniques, including brainstorming , root cause analysis , process mapping , and Ishikawa diagrams . Each of these techniques has its own advantages and disadvantages and can be used in a variety of situations depending on the nature of the problem.

Best Practice for Defining the Problem

In addition to brainstorming, root cause analysis, process mapping, and Ishikawa diagram s, best practices should be followed when defining a problem in A3 Problem Solving. Among these best practices are:

- Define the issue in a specific and quantifiable way: It is critical to be specific and concise when defining the problem, as well as to quantify the problem in terms of its impact. This will help to ensure that all stakeholders understand the problem and that data collection is focused on the right areas.

- Focus on the problem’s root cause: The A3 Problem Solving methodology is intended to assist organisations in identifying and addressing the root cause of a problem, rather than just the symptoms. Organizations can ensure that their solutions are effective and long-lasting by focusing on the root cause of the problem.

- Ascertain that all stakeholders agree on the problem’s definition: All stakeholders must agree on the definition of the problem for the A3 Problem Solving process to be effective. This ensures that everyone is working towards the same goal and that the solutions developed are relevant and appropriate.

- Consider the problem’s impact on the organisation and its stakeholders: It is critical to consider the impact of the problem on the organisation and its stakeholders when defining it. This will assist in ensuring that the appropriate data is gathered and that the solutions developed are relevant and appropriate.

Organizations can ensure that their problem is defined in a way that allows for effective data collection, analysis, and solution development by following these best practices. This will aid in the development of appropriate solutions and the effective resolution of the problem, resulting in improvements in the organization’s processes and outcomes.

Step 2: Gather Data

Gathering data in a3 problem solving.

Data collection is an important step in the A3 Problem Solving process because it allows organisations to gain a thorough understanding of the problem they are attempting to solve. This step entails gathering pertinent information about the problem, such as data on its origin, impact, and any related factors. This information is then used to help identify root causes and develop effective solutions.

One of the most important advantages of data collection in A3 Problem Solving is that it allows organisations to identify patterns and trends in data, which can be useful in determining the root cause of the problem. This information can then be used to create effective solutions that address the problem’s root cause rather than just its symptoms.

In A3 Problem Solving, data collection is a collaborative effort involving all stakeholders, including those directly impacted by the problem and those with relevant expertise or experience. Stakeholders can ensure that all relevant information is collected and that the data is accurate and complete by working together.

Overall, data collection is an important step in the A3 Problem Solving process because it serves as the foundation for effective problem-solving. Organizations can gain a deep understanding of the problem they are attempting to solve and develop effective solutions that address its root cause by collecting and analysing relevant data.

Data Collection Methods

In A3 Problem Solving, several data collection methods are available, including:

- Observations

- Process diagrams

The best data collection method will be determined by the problem being solved and the type of data required. To gain a complete understanding of the problem, it is critical to use multiple data collection methods.

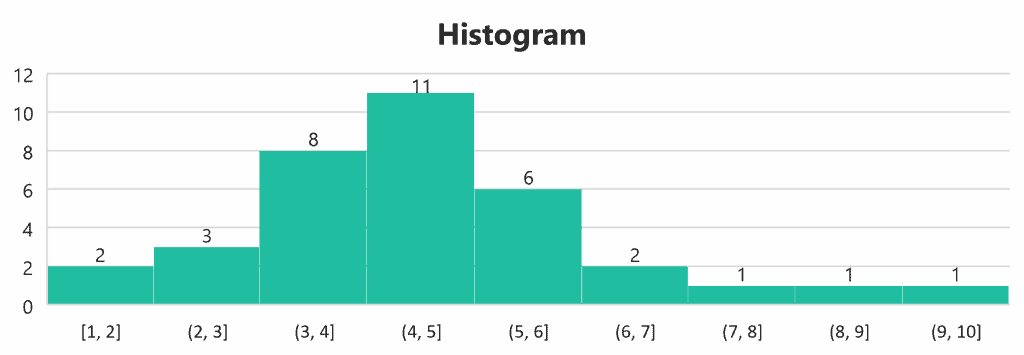

Tools for Data Analysis and Visualization

Once the data has been collected, it must be analysed and visualised in order to gain insights into the problem. This process can be aided by the following tools:

- Excel Spreadsheets

- Flow diagrams

- Pareto diagrams

- Scatter Plots

- Control diagrams

These tools can assist in organising data and making it easier to understand. They can also be used to generate visual representations of data, such as graphs and charts, to communicate the findings to others.

Finally, the data collection and analysis step is an important part of the A3 Problem Solving process. Organizations can gain a better understanding of the problem and develop effective solutions by collecting and analysing relevant data.

Step 3: Identify Root Causes

Identifying the root causes of the problem is the third step in the A3 Problem Solving process. This step is critical because it assists organisations in understanding the root causes of a problem rather than just its symptoms. Once the underlying cause of the problem is identified, it can be addressed more effectively, leading to more long-term solutions.

Overview of the Root Cause Analysis Process

The process of determining the underlying causes of a problem is known as root cause analysis. This process can assist organisations in determining why a problem is occurring and what can be done to prevent it from recurring in the future. The goal of root cause analysis is to identify the underlying cause of a problem rather than just its symptoms, allowing it to be addressed more effectively.

To understand Root cause analysis in more detail check out RCA in our Lean Six Sigma Yellow Belt Course Root Cause Analysis section

Techniques for Identifying Root Causes

There are several techniques for determining the root causes of a problem, including:

- Brainstorming

- Ishikawa diagrams (also known as fishbone diagrams)

- Root Cause Tree Analysis

These methods can be used to investigate the issue in-depth and identify potential root causes. Organizations can gain a deeper understanding of the problem and identify the underlying causes that must be addressed by using these techniques.

Best Practices for Conducting Root Cause Analysis

It is critical to follow these best practices when conducting root cause analysis in A3 Problem Solving:

- Make certain that all stakeholders participate in the root cause analysis process.

- Concentrate on determining the root cause of the problem rather than just its symptoms.

- Take into account all potential root causes, not just the most obvious ones.

- To identify root causes, use a systematic approach, such as the 5 Whys or root cause tree analysis.

Organizations can ensure that root cause analysis is carried out effectively and that the root cause of the problem is identified by adhering to these best practises. This will aid in the development of appropriate solutions and the effective resolution of the problem.

Step 4: Develop Solutions

Developing solutions is the fourth step in the A3 Problem Solving process. This entails generating ideas and options for dealing with the problem, followed by selecting the best solution. The goal is to develop a solution that addresses the root cause of the problem and prevents it from recurring.

Solution Development in A3 Problem Solving

A3 solution development Problem solving is an iterative process in which options are generated and evaluated. The data gathered in the previous steps, as well as the insights and understanding gained from the root cause analysis, guide this process. The solution should be based on a thorough understanding of the problem and address the underlying cause.

Techniques for Developing Solutions

There are several techniques that can be used to develop solutions in A3 Problem Solving, including:

- Brainwriting

- Solution matrix

- Multi voting

- Force field analysis

These techniques can help to generate a range of options and to select the best solution.

Best Practice for Developing Solutions

It is critical to follow the following best practices when developing solutions in A3 Problem Solving:

- Participate in the solution development process with all stakeholders.

- Make certain that the solution addresses the underlying cause of the problem.

- Make certain that the solution is feasible and achievable.

- Consider the solution’s impact on the organisation and its stakeholders.

Organizations can ensure that the solutions they develop are effective and sustainable by adhering to these best practises. This will help to ensure that the problem is addressed effectively and that it does not reoccur.

Step 5: Implement Solutions

The final and most important step in the A3 Problem Solving methodology is solution implementation. This is the stage at which the identified and developed solutions are put into action to address the problem. This step’s goal is to ensure that the solutions are effective, efficient, and long-lasting.

The implementation Process

The implementation process entails putting the solutions developed in the previous step into action. This could include changes to processes, procedures, and systems, as well as employee training and education. To ensure that the solutions are effective, the implementation process should be well-planned and meticulously executed.

Techniques for Implementing Solutions

A3 Problem Solving solutions can be implemented using a variety of techniques, including:

- Piloting the solution on a small scale before broadening its application

- Participating in the implementation process with all relevant stakeholders

- ensuring that the solution is in line with the goals and objectives of the organisation

- Monitoring the solution to determine its effectiveness and make any necessary changes

Best Practice for Implementing Solutions

It is critical to follow these best practices when implementing solutions in A3 Problem Solving:

Make certain that all relevant stakeholders are involved and supportive of the solution. Have a clear implementation plan that outlines the steps, timeline, and resources required. Continuously monitor and evaluate the solution to determine its efficacy and make any necessary changes. Encourage all stakeholders to communicate and collaborate openly. Organizations can ensure that solutions are effectively implemented and problems are effectively addressed by adhering to these best practices. The ultimate goal is to find a long-term solution to the problem and improve the organization’s overall performance.

In conclusion, A3 Problem Solving is a comprehensive and structured methodology for problem-solving that can be applied in various industries and organisations. The A3 Problem Solving process’s five steps – Define the Problem, Gather Data, Identify Root Causes, Develop Solutions, and Implement Solutions – provide a road map for effectively addressing problems and making long-term improvements.

Organizations can improve their problem-solving skills and achieve better results by following the key principles, techniques, and best practices outlined in this guide. As a result, both the organisation and its stakeholders will benefit from increased efficiency, effectiveness, and satisfaction. So, whether you’re an experienced problem solver or just getting started, consider incorporating the A3 Problem Solving methodology into your work and start reaping the benefits right away.

Was this helpful?

Daniel Croft

Hi im Daniel continuous improvement manager with a Black Belt in Lean Six Sigma and over 10 years of real-world experience across a range sectors, I have a passion for optimizing processes and creating a culture of efficiency. I wanted to create Learn Lean Siigma to be a platform dedicated to Lean Six Sigma and process improvement insights and provide all the guides, tools, techniques and templates I looked for in one place as someone new to the world of Lean Six Sigma and Continuous improvement.

5 Simple Steps to Sustain 5S in Your Organization for Long-Term Success

Getting Started with Lean Six Sigma: A Guide to Launching Your First Project

Free lean six sigma templates.

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Understanding Process Performance: Pp and Ppk

Understand Process Performance (Pp) and Process Performance Index (Ppk) to assess and improve manufacturing processes.…

LIFO or FIFO for Stock Management?

Choosing between LIFO and FIFO for stock management depends on factors like product nature, market…

Are There Any Official Standards for Six Sigma?

Are there any official standards for Six Sigma? While Six Sigma is a well-defined methodology…

5S Floor Marking Best Practices

In lean manufacturing, the 5S System is a foundational tool, involving the steps: Sort, Set…

How to Measure the ROI of Continuous Improvement Initiatives

When it comes to business, knowing the value you’re getting for your money is crucial,…

8D Problem-Solving: Common Mistakes to Avoid

In today’s competitive business landscape, effective problem-solving is the cornerstone of organizational success. The 8D…

How to master the seven-step problem-solving process

In this episode of the McKinsey Podcast , Simon London speaks with Charles Conn, CEO of venture-capital firm Oxford Sciences Innovation, and McKinsey senior partner Hugo Sarrazin about the complexities of different problem-solving strategies.

Podcast transcript

Simon London: Hello, and welcome to this episode of the McKinsey Podcast , with me, Simon London. What’s the number-one skill you need to succeed professionally? Salesmanship, perhaps? Or a facility with statistics? Or maybe the ability to communicate crisply and clearly? Many would argue that at the very top of the list comes problem solving: that is, the ability to think through and come up with an optimal course of action to address any complex challenge—in business, in public policy, or indeed in life.

Looked at this way, it’s no surprise that McKinsey takes problem solving very seriously, testing for it during the recruiting process and then honing it, in McKinsey consultants, through immersion in a structured seven-step method. To discuss the art of problem solving, I sat down in California with McKinsey senior partner Hugo Sarrazin and also with Charles Conn. Charles is a former McKinsey partner, entrepreneur, executive, and coauthor of the book Bulletproof Problem Solving: The One Skill That Changes Everything [John Wiley & Sons, 2018].

Charles and Hugo, welcome to the podcast. Thank you for being here.

Hugo Sarrazin: Our pleasure.

Charles Conn: It’s terrific to be here.

Simon London: Problem solving is a really interesting piece of terminology. It could mean so many different things. I have a son who’s a teenage climber. They talk about solving problems. Climbing is problem solving. Charles, when you talk about problem solving, what are you talking about?

Charles Conn: For me, problem solving is the answer to the question “What should I do?” It’s interesting when there’s uncertainty and complexity, and when it’s meaningful because there are consequences. Your son’s climbing is a perfect example. There are consequences, and it’s complicated, and there’s uncertainty—can he make that grab? I think we can apply that same frame almost at any level. You can think about questions like “What town would I like to live in?” or “Should I put solar panels on my roof?”

You might think that’s a funny thing to apply problem solving to, but in my mind it’s not fundamentally different from business problem solving, which answers the question “What should my strategy be?” Or problem solving at the policy level: “How do we combat climate change?” “Should I support the local school bond?” I think these are all part and parcel of the same type of question, “What should I do?”

I’m a big fan of structured problem solving. By following steps, we can more clearly understand what problem it is we’re solving, what are the components of the problem that we’re solving, which components are the most important ones for us to pay attention to, which analytic techniques we should apply to those, and how we can synthesize what we’ve learned back into a compelling story. That’s all it is, at its heart.

I think sometimes when people think about seven steps, they assume that there’s a rigidity to this. That’s not it at all. It’s actually to give you the scope for creativity, which often doesn’t exist when your problem solving is muddled.

Simon London: You were just talking about the seven-step process. That’s what’s written down in the book, but it’s a very McKinsey process as well. Without getting too deep into the weeds, let’s go through the steps, one by one. You were just talking about problem definition as being a particularly important thing to get right first. That’s the first step. Hugo, tell us about that.

Hugo Sarrazin: It is surprising how often people jump past this step and make a bunch of assumptions. The most powerful thing is to step back and ask the basic questions—“What are we trying to solve? What are the constraints that exist? What are the dependencies?” Let’s make those explicit and really push the thinking and defining. At McKinsey, we spend an enormous amount of time in writing that little statement, and the statement, if you’re a logic purist, is great. You debate. “Is it an ‘or’? Is it an ‘and’? What’s the action verb?” Because all these specific words help you get to the heart of what matters.

Want to subscribe to The McKinsey Podcast ?

Simon London: So this is a concise problem statement.

Hugo Sarrazin: Yeah. It’s not like “Can we grow in Japan?” That’s interesting, but it is “What, specifically, are we trying to uncover in the growth of a product in Japan? Or a segment in Japan? Or a channel in Japan?” When you spend an enormous amount of time, in the first meeting of the different stakeholders, debating this and having different people put forward what they think the problem definition is, you realize that people have completely different views of why they’re here. That, to me, is the most important step.

Charles Conn: I would agree with that. For me, the problem context is critical. When we understand “What are the forces acting upon your decision maker? How quickly is the answer needed? With what precision is the answer needed? Are there areas that are off limits or areas where we would particularly like to find our solution? Is the decision maker open to exploring other areas?” then you not only become more efficient, and move toward what we call the critical path in problem solving, but you also make it so much more likely that you’re not going to waste your time or your decision maker’s time.

How often do especially bright young people run off with half of the idea about what the problem is and start collecting data and start building models—only to discover that they’ve really gone off half-cocked.

Hugo Sarrazin: Yeah.

Charles Conn: And in the wrong direction.

Simon London: OK. So step one—and there is a real art and a structure to it—is define the problem. Step two, Charles?

Charles Conn: My favorite step is step two, which is to use logic trees to disaggregate the problem. Every problem we’re solving has some complexity and some uncertainty in it. The only way that we can really get our team working on the problem is to take the problem apart into logical pieces.

What we find, of course, is that the way to disaggregate the problem often gives you an insight into the answer to the problem quite quickly. I love to do two or three different cuts at it, each one giving a bit of a different insight into what might be going wrong. By doing sensible disaggregations, using logic trees, we can figure out which parts of the problem we should be looking at, and we can assign those different parts to team members.

Simon London: What’s a good example of a logic tree on a sort of ratable problem?

Charles Conn: Maybe the easiest one is the classic profit tree. Almost in every business that I would take a look at, I would start with a profit or return-on-assets tree. In its simplest form, you have the components of revenue, which are price and quantity, and the components of cost, which are cost and quantity. Each of those can be broken out. Cost can be broken into variable cost and fixed cost. The components of price can be broken into what your pricing scheme is. That simple tree often provides insight into what’s going on in a business or what the difference is between that business and the competitors.

If we add the leg, which is “What’s the asset base or investment element?”—so profit divided by assets—then we can ask the question “Is the business using its investments sensibly?” whether that’s in stores or in manufacturing or in transportation assets. I hope we can see just how simple this is, even though we’re describing it in words.

When I went to work with Gordon Moore at the Moore Foundation, the problem that he asked us to look at was “How can we save Pacific salmon?” Now, that sounds like an impossible question, but it was amenable to precisely the same type of disaggregation and allowed us to organize what became a 15-year effort to improve the likelihood of good outcomes for Pacific salmon.

Simon London: Now, is there a danger that your logic tree can be impossibly large? This, I think, brings us onto the third step in the process, which is that you have to prioritize.

Charles Conn: Absolutely. The third step, which we also emphasize, along with good problem definition, is rigorous prioritization—we ask the questions “How important is this lever or this branch of the tree in the overall outcome that we seek to achieve? How much can I move that lever?” Obviously, we try and focus our efforts on ones that have a big impact on the problem and the ones that we have the ability to change. With salmon, ocean conditions turned out to be a big lever, but not one that we could adjust. We focused our attention on fish habitats and fish-harvesting practices, which were big levers that we could affect.

People spend a lot of time arguing about branches that are either not important or that none of us can change. We see it in the public square. When we deal with questions at the policy level—“Should you support the death penalty?” “How do we affect climate change?” “How can we uncover the causes and address homelessness?”—it’s even more important that we’re focusing on levers that are big and movable.

Would you like to learn more about our Strategy & Corporate Finance Practice ?

Simon London: Let’s move swiftly on to step four. You’ve defined your problem, you disaggregate it, you prioritize where you want to analyze—what you want to really look at hard. Then you got to the work plan. Now, what does that mean in practice?

Hugo Sarrazin: Depending on what you’ve prioritized, there are many things you could do. It could be breaking the work among the team members so that people have a clear piece of the work to do. It could be defining the specific analyses that need to get done and executed, and being clear on time lines. There’s always a level-one answer, there’s a level-two answer, there’s a level-three answer. Without being too flippant, I can solve any problem during a good dinner with wine. It won’t have a whole lot of backing.

Simon London: Not going to have a lot of depth to it.

Hugo Sarrazin: No, but it may be useful as a starting point. If the stakes are not that high, that could be OK. If it’s really high stakes, you may need level three and have the whole model validated in three different ways. You need to find a work plan that reflects the level of precision, the time frame you have, and the stakeholders you need to bring along in the exercise.

Charles Conn: I love the way you’ve described that, because, again, some people think of problem solving as a linear thing, but of course what’s critical is that it’s iterative. As you say, you can solve the problem in one day or even one hour.

Charles Conn: We encourage our teams everywhere to do that. We call it the one-day answer or the one-hour answer. In work planning, we’re always iterating. Every time you see a 50-page work plan that stretches out to three months, you know it’s wrong. It will be outmoded very quickly by that learning process that you described. Iterative problem solving is a critical part of this. Sometimes, people think work planning sounds dull, but it isn’t. It’s how we know what’s expected of us and when we need to deliver it and how we’re progressing toward the answer. It’s also the place where we can deal with biases. Bias is a feature of every human decision-making process. If we design our team interactions intelligently, we can avoid the worst sort of biases.

Simon London: Here we’re talking about cognitive biases primarily, right? It’s not that I’m biased against you because of your accent or something. These are the cognitive biases that behavioral sciences have shown we all carry around, things like anchoring, overoptimism—these kinds of things.

Both: Yeah.

Charles Conn: Availability bias is the one that I’m always alert to. You think you’ve seen the problem before, and therefore what’s available is your previous conception of it—and we have to be most careful about that. In any human setting, we also have to be careful about biases that are based on hierarchies, sometimes called sunflower bias. I’m sure, Hugo, with your teams, you make sure that the youngest team members speak first. Not the oldest team members, because it’s easy for people to look at who’s senior and alter their own creative approaches.

Hugo Sarrazin: It’s helpful, at that moment—if someone is asserting a point of view—to ask the question “This was true in what context?” You’re trying to apply something that worked in one context to a different one. That can be deadly if the context has changed, and that’s why organizations struggle to change. You promote all these people because they did something that worked well in the past, and then there’s a disruption in the industry, and they keep doing what got them promoted even though the context has changed.

Simon London: Right. Right.

Hugo Sarrazin: So it’s the same thing in problem solving.

Charles Conn: And it’s why diversity in our teams is so important. It’s one of the best things about the world that we’re in now. We’re likely to have people from different socioeconomic, ethnic, and national backgrounds, each of whom sees problems from a slightly different perspective. It is therefore much more likely that the team will uncover a truly creative and clever approach to problem solving.

Simon London: Let’s move on to step five. You’ve done your work plan. Now you’ve actually got to do the analysis. The thing that strikes me here is that the range of tools that we have at our disposal now, of course, is just huge, particularly with advances in computation, advanced analytics. There’s so many things that you can apply here. Just talk about the analysis stage. How do you pick the right tools?

Charles Conn: For me, the most important thing is that we start with simple heuristics and explanatory statistics before we go off and use the big-gun tools. We need to understand the shape and scope of our problem before we start applying these massive and complex analytical approaches.

Simon London: Would you agree with that?

Hugo Sarrazin: I agree. I think there are so many wonderful heuristics. You need to start there before you go deep into the modeling exercise. There’s an interesting dynamic that’s happening, though. In some cases, for some types of problems, it is even better to set yourself up to maximize your learning. Your problem-solving methodology is test and learn, test and learn, test and learn, and iterate. That is a heuristic in itself, the A/B testing that is used in many parts of the world. So that’s a problem-solving methodology. It’s nothing different. It just uses technology and feedback loops in a fast way. The other one is exploratory data analysis. When you’re dealing with a large-scale problem, and there’s so much data, I can get to the heuristics that Charles was talking about through very clever visualization of data.

You test with your data. You need to set up an environment to do so, but don’t get caught up in neural-network modeling immediately. You’re testing, you’re checking—“Is the data right? Is it sound? Does it make sense?”—before you launch too far.

Simon London: You do hear these ideas—that if you have a big enough data set and enough algorithms, they’re going to find things that you just wouldn’t have spotted, find solutions that maybe you wouldn’t have thought of. Does machine learning sort of revolutionize the problem-solving process? Or are these actually just other tools in the toolbox for structured problem solving?

Charles Conn: It can be revolutionary. There are some areas in which the pattern recognition of large data sets and good algorithms can help us see things that we otherwise couldn’t see. But I do think it’s terribly important we don’t think that this particular technique is a substitute for superb problem solving, starting with good problem definition. Many people use machine learning without understanding algorithms that themselves can have biases built into them. Just as 20 years ago, when we were doing statistical analysis, we knew that we needed good model definition, we still need a good understanding of our algorithms and really good problem definition before we launch off into big data sets and unknown algorithms.

Simon London: Step six. You’ve done your analysis.

Charles Conn: I take six and seven together, and this is the place where young problem solvers often make a mistake. They’ve got their analysis, and they assume that’s the answer, and of course it isn’t the answer. The ability to synthesize the pieces that came out of the analysis and begin to weave those into a story that helps people answer the question “What should I do?” This is back to where we started. If we can’t synthesize, and we can’t tell a story, then our decision maker can’t find the answer to “What should I do?”

Simon London: But, again, these final steps are about motivating people to action, right?

Charles Conn: Yeah.

Simon London: I am slightly torn about the nomenclature of problem solving because it’s on paper, right? Until you motivate people to action, you actually haven’t solved anything.

Charles Conn: I love this question because I think decision-making theory, without a bias to action, is a waste of time. Everything in how I approach this is to help people take action that makes the world better.

Simon London: Hence, these are absolutely critical steps. If you don’t do this well, you’ve just got a bunch of analysis.

Charles Conn: We end up in exactly the same place where we started, which is people speaking across each other, past each other in the public square, rather than actually working together, shoulder to shoulder, to crack these important problems.

Simon London: In the real world, we have a lot of uncertainty—arguably, increasing uncertainty. How do good problem solvers deal with that?

Hugo Sarrazin: At every step of the process. In the problem definition, when you’re defining the context, you need to understand those sources of uncertainty and whether they’re important or not important. It becomes important in the definition of the tree.

You need to think carefully about the branches of the tree that are more certain and less certain as you define them. They don’t have equal weight just because they’ve got equal space on the page. Then, when you’re prioritizing, your prioritization approach may put more emphasis on things that have low probability but huge impact—or, vice versa, may put a lot of priority on things that are very likely and, hopefully, have a reasonable impact. You can introduce that along the way. When you come back to the synthesis, you just need to be nuanced about what you’re understanding, the likelihood.

Often, people lack humility in the way they make their recommendations: “This is the answer.” They’re very precise, and I think we would all be well-served to say, “This is a likely answer under the following sets of conditions” and then make the level of uncertainty clearer, if that is appropriate. It doesn’t mean you’re always in the gray zone; it doesn’t mean you don’t have a point of view. It just means that you can be explicit about the certainty of your answer when you make that recommendation.

Simon London: So it sounds like there is an underlying principle: “Acknowledge and embrace the uncertainty. Don’t pretend that it isn’t there. Be very clear about what the uncertainties are up front, and then build that into every step of the process.”

Hugo Sarrazin: Every step of the process.

Simon London: Yeah. We have just walked through a particular structured methodology for problem solving. But, of course, this is not the only structured methodology for problem solving. One that is also very well-known is design thinking, which comes at things very differently. So, Hugo, I know you have worked with a lot of designers. Just give us a very quick summary. Design thinking—what is it, and how does it relate?

Hugo Sarrazin: It starts with an incredible amount of empathy for the user and uses that to define the problem. It does pause and go out in the wild and spend an enormous amount of time seeing how people interact with objects, seeing the experience they’re getting, seeing the pain points or joy—and uses that to infer and define the problem.

Simon London: Problem definition, but out in the world.

Hugo Sarrazin: With an enormous amount of empathy. There’s a huge emphasis on empathy. Traditional, more classic problem solving is you define the problem based on an understanding of the situation. This one almost presupposes that we don’t know the problem until we go see it. The second thing is you need to come up with multiple scenarios or answers or ideas or concepts, and there’s a lot of divergent thinking initially. That’s slightly different, versus the prioritization, but not for long. Eventually, you need to kind of say, “OK, I’m going to converge again.” Then you go and you bring things back to the customer and get feedback and iterate. Then you rinse and repeat, rinse and repeat. There’s a lot of tactile building, along the way, of prototypes and things like that. It’s very iterative.

Simon London: So, Charles, are these complements or are these alternatives?

Charles Conn: I think they’re entirely complementary, and I think Hugo’s description is perfect. When we do problem definition well in classic problem solving, we are demonstrating the kind of empathy, at the very beginning of our problem, that design thinking asks us to approach. When we ideate—and that’s very similar to the disaggregation, prioritization, and work-planning steps—we do precisely the same thing, and often we use contrasting teams, so that we do have divergent thinking. The best teams allow divergent thinking to bump them off whatever their initial biases in problem solving are. For me, design thinking gives us a constant reminder of creativity, empathy, and the tactile nature of problem solving, but it’s absolutely complementary, not alternative.

Simon London: I think, in a world of cross-functional teams, an interesting question is do people with design-thinking backgrounds really work well together with classical problem solvers? How do you make that chemistry happen?

Hugo Sarrazin: Yeah, it is not easy when people have spent an enormous amount of time seeped in design thinking or user-centric design, whichever word you want to use. If the person who’s applying classic problem-solving methodology is very rigid and mechanical in the way they’re doing it, there could be an enormous amount of tension. If there’s not clarity in the role and not clarity in the process, I think having the two together can be, sometimes, problematic.

The second thing that happens often is that the artifacts the two methodologies try to gravitate toward can be different. Classic problem solving often gravitates toward a model; design thinking migrates toward a prototype. Rather than writing a big deck with all my supporting evidence, they’ll bring an example, a thing, and that feels different. Then you spend your time differently to achieve those two end products, so that’s another source of friction.

Now, I still think it can be an incredibly powerful thing to have the two—if there are the right people with the right mind-set, if there is a team that is explicit about the roles, if we’re clear about the kind of outcomes we are attempting to bring forward. There’s an enormous amount of collaborativeness and respect.

Simon London: But they have to respect each other’s methodology and be prepared to flex, maybe, a little bit, in how this process is going to work.

Hugo Sarrazin: Absolutely.

Simon London: The other area where, it strikes me, there could be a little bit of a different sort of friction is this whole concept of the day-one answer, which is what we were just talking about in classical problem solving. Now, you know that this is probably not going to be your final answer, but that’s how you begin to structure the problem. Whereas I would imagine your design thinkers—no, they’re going off to do their ethnographic research and get out into the field, potentially for a long time, before they come back with at least an initial hypothesis.

Want better strategies? Become a bulletproof problem solver

Hugo Sarrazin: That is a great callout, and that’s another difference. Designers typically will like to soak into the situation and avoid converging too quickly. There’s optionality and exploring different options. There’s a strong belief that keeps the solution space wide enough that you can come up with more radical ideas. If there’s a large design team or many designers on the team, and you come on Friday and say, “What’s our week-one answer?” they’re going to struggle. They’re not going to be comfortable, naturally, to give that answer. It doesn’t mean they don’t have an answer; it’s just not where they are in their thinking process.

Simon London: I think we are, sadly, out of time for today. But Charles and Hugo, thank you so much.

Charles Conn: It was a pleasure to be here, Simon.

Hugo Sarrazin: It was a pleasure. Thank you.

Simon London: And thanks, as always, to you, our listeners, for tuning into this episode of the McKinsey Podcast . If you want to learn more about problem solving, you can find the book, Bulletproof Problem Solving: The One Skill That Changes Everything , online or order it through your local bookstore. To learn more about McKinsey, you can of course find us at McKinsey.com.

Charles Conn is CEO of Oxford Sciences Innovation and an alumnus of McKinsey’s Sydney office. Hugo Sarrazin is a senior partner in the Silicon Valley office, where Simon London, a member of McKinsey Publishing, is also based.

Explore a career with us

Related articles.

Strategy to beat the odds

Five routes to more innovative problem solving

- Product overview

- All features

- Latest feature release

- App integrations

CAPABILITIES

- project icon Project management

- Project views

- Custom fields

- Status updates

- goal icon Goals and reporting

- Reporting dashboards

- workflow icon Workflows and automation

- portfolio icon Resource management

- Capacity planning

- Time tracking

- my-task icon Admin and security

- Admin console

- asana-intelligence icon Asana AI

- list icon Personal

- premium icon Starter

- briefcase icon Advanced

- Goal management

- Organizational planning

- Campaign management

- Creative production

- Content calendars

- Marketing strategic planning

- Resource planning

- Project intake

- Product launches

- Employee onboarding

- View all uses arrow-right icon

- Project plans

- Team goals & objectives

- Team continuity

- Meeting agenda

- View all templates arrow-right icon

- Work management resources Discover best practices, watch webinars, get insights

- Customer stories See how the world's best organizations drive work innovation with Asana

- Help Center Get lots of tips, tricks, and advice to get the most from Asana

- Asana Academy Sign up for interactive courses and webinars to learn Asana

- Developers Learn more about building apps on the Asana platform

- Community programs Connect with and learn from Asana customers around the world

- Events Find out about upcoming events near you

- Partners Learn more about our partner programs

- Asana for nonprofits Get more information on our nonprofit discount program, and apply.

Featured Reads

- Project management |

- What is 8D? A template for efficient pr ...

What is 8D? A template for efficient problem-solving

How you respond when problems arise is one of the most defining qualities of a manager. Luckily, there are tools you can use to master problem-solving. The 8D method of problem-solving combines teamwork and basic statistics to help you reach a logical solution and prevent new issues from arising.

You’ve spent months overseeing the development of your company's newest project. From initiation, planning, and execution, you’re confident this may be your best work yet.

Until the feedback starts rolling in.

There’s no sugar-coating it—things don’t always go as planned. But production or process issues are hardly a signal to throw in the towel. Instead, focus on honing your problem-solving skills to find a solution that keeps it from happening again.

The 8D method of problem solving emphasizes the importance of teamwork to not only solve your process woes but prevent new ones from occurring. In this guide, we’ll break down what 8D is, how to use this methodology, and the benefits it can give to you and your team. Plus, get an 8D template to make solving your issue easier.

What is 8D?

The eight disciplines (8D) method is a problem-solving approach that identifies, corrects, and eliminates recurring problems. By determining the root causes of a problem, managers can use this method to establish a permanent corrective action and prevent recurring issues.

How do you use the 8D method?

The 8D method is a proven strategy for avoiding long-term damage from recurring problems. If you’re noticing issues in your workflow or processes, then it’s a good time to give this problem-solving method a try.

To complete an 8D analysis, follow “the eight disciplines” to construct a statistical analysis of the problem and determine the best solution.

The eight disciplines of problem-solving

8D stands for the eight disciplines you will use to establish an 8D report. As you may notice, this outline starts with zero, which makes nine total disciplines. The “zero stage” was developed later as an initial planning stage.

To illustrate these steps, imagine your organization experienced a decline in team innovation and productivity this past year. Your stakeholders have noticed and want to see changes implemented within the next six months. Below, we’ll use the 8D process to uncover a morale-boosting solution.

![qa workbook the problem solving approach [inline illustration] D8 problem solving approach (infographic)](https://assets.asana.biz/transform/6ab7c188-3258-4d2e-afe6-9a4a084cc09f/inline-productivity-8d-template-1-2x?io=transform:fill,width:2560&format=webp)

D0: Prepare and plan

Before starting the problem-solving process, evaluate the problem you want to solve. Understanding the background of the problem will help you identify the root cause in later steps.

Collect information about how the problem has affected a process or product and what the most severe consequences may be. Planning can include:

Gathering data

Determining the prerequisites for solving the problem

Collecting feedback from others involved

![qa workbook the problem solving approach [inline illustration] D0 Planning (example)](https://assets.asana.biz/transform/abc3621d-e1ae-47ff-b731-0ee38cff99e9/inline-productivity-8d-template-2-2x?io=transform:fill,width:2560&format=webp)

If we look back at our example, you may want to figure out whether this decline in morale is organization-wide or only applies to a few departments. Consider interviewing a few employees from different departments and levels of management to gain some perspective. Next, determine what knowledge and skills you will need to solve this lapse in productivity.

D1: Form your team

Create a cross-functional team made up of people who have knowledge of the various products and workflows involved. These team members should have the skills needed to solve the problem and put corrective actions in place.

Steps in this discipline may include:

Appointing a team leader

Developing and implementing team guidelines

Determining team goals and priorities

Assigning individual roles

Arranging team-building activities

![qa workbook the problem solving approach [inline illustration] D1 Team members (example)](https://assets.asana.biz/transform/51986017-5150-4dd4-940c-252cd0eb8ba5/inline-productivity-8d-template-3-2x?io=transform:fill,width:2560&format=webp)

From our example, a solid team would consist of people with first-hand experience with the issues—like representatives from all departments and key people close to workshop-level work. You may also want to pull someone in from your HR department to help design and implement a solution. Most importantly, make sure the people you choose want to be involved and contribute to the solution.

D2: Identify the problem

You may have a good understanding of your problem by now, but this phase aims to break it down into clear and quantifiable terms by identifying the five W’s a and two H’s (5W2H):

Who first reported the problem?

What is the problem about?

When did it occur and how often?

Where did it occur (relating to the sector, supplier, machine, or production line involved)?

Why is solving the problem important?

How was the problem first detected?

How many parts/units/customers are affected?

![qa workbook the problem solving approach [inline illustration] D2 Problem statement & description (example)](https://assets.asana.biz/transform/9825ecd6-2bd3-4559-a68c-b1ae8aca2e52/inline-productivity-8d-template-4-2x?io=transform:fill,width:2560&format=webp)

Use your team’s insights to answer these questions. From our example, your team may conclude that:

Employees feel overwhelmed with their current workload.

There is no real structure or opportunity to share new ideas.

Managers have had no training for meetings or innovation settings.

Disgruntled employees know they can achieve more—and want to achieve more—even if they seem disengaged.

Once you answer these questions, record an official problem statement to describe the issue. If possible, include photos, videos, and diagrams to ensure all parties have a clear understanding of the problem. It may also help to create a flowchart of the process that includes various steps related to the problem description.

D3: Develop an interim containment plan

Much like we can expect speedy first aid after an accident, your team should take immediate actions to ensure you contain the problem—especially if the problem is related to customer safety.

An interim containment plan will provide a temporary solution to isolate the problem from customers and clients while your team works to develop a permanent corrective action. This band-aid will help keep your customers informed and safe—and your reputation intact.

![qa workbook the problem solving approach [inline illustration] D3 Interim containment action (example)](https://assets.asana.biz/transform/d6279c36-ccc6-4de3-89d2-f221632a1059/inline-productivity-8d-template-5-2x?io=transform:fill,width:2560&format=webp)

Because your findings revealed workers were overworked and managers lacked training, your team suggests scheduling a few mandatory training sessions for leaders of each department covering time and stress management and combating burnout . You may also want to have a presentation outlining the topics of this training to get key managers and stakeholders interested and primed for positive upcoming changes.

D4: Verify root causes and escape points

Refer back to your findings and consult with your team about how the problem may have occurred. The root cause analysis involves mapping each potential root cause against the problem statement and its related test data. Make sure to test all potential causes—fuzzy brainstorming and sloppy analyses may cause you to overlook vital information.

![qa workbook the problem solving approach [inline illustration] D4 Root cause & escape points (example)](https://assets.asana.biz/transform/301717c6-0434-4c88-addf-d500dc23ae87/inline-productivity-8d-template-6-2x?io=transform:fill,width:2560&format=webp)

In our example, focus on the “why” portion of the 5W2H. You and your team identify six root causes:

Managers have never had any training

There is a lack of trust and psychological safety

Employees don’t understand the objectives and goals

Communication is poor

Time management is poor

Employees lack confidence

In addition to identifying the root causes, try to pinpoint where you first detected the problem in the process, and why it went unnoticed. This is called the escape point, and there may be more than one.

D5: Choose permanent corrective actions

Work with your team to determine the most likely solution to remove the root cause of the problem and address the issues with the escape points. Quantitatively confirm that the selected permanent corrective action(s) (PCA) will resolve the problem for the customer.

Steps to choosing a PCA may include:

Determining if you require further expertise

Ensuring the 5W2Hs are defined correctly

Carrying out a decision analysis and risk assessment

Considering alternative measures

Collecting evidence to prove the PCA will be effective

![qa workbook the problem solving approach [inline illustration] D5 Permanent corrective action (example)](https://assets.asana.biz/transform/53509966-18dd-4bb4-88a1-c7ca940fde3f/inline-productivity-8d-template-7-2x?io=transform:fill,width:2560&format=webp)

Your team decides to roll out the training used in the interim plan to all employees, with monthly company-wide workshops on improving well-being. You also plan to implement meetings, innovation sessions, and team-coaching training for managers. Lastly, you suggest adopting software to improve communication and collaboration.

D6: Implement your corrective actions

Once all parties have agreed on a solution, the next step is to create an action plan to remove the root causes and escape points. Once the solution is in effect, you can remove your interim containment actions.

After seeing success with the training in the interim phase, your stakeholders approve all of your team’s proposed PCAs. Your representative from HR also plans to implement periodic employee wellness checks to track employee morale .

![qa workbook the problem solving approach [inline illustration] D6 PCA implementation plan (example)](https://assets.asana.biz/transform/ca68af4a-afa7-4be4-93cb-8a8321eb5172/inline-productivity-8d-template-8-2x?io=transform:fill,width:2560&format=webp)

To ensure your corrective action was a success, monitor the results, customer, or employee feedback over a long period of time and take note of any negative effects. Setting up “controls” like employee wellness checks will help you validate whether your solution is working or more needs to be done.

D7: Take preventive measures

One of the main benefits of using the 8D method is the improved ability to identify necessary systematic changes to prevent future issues from occurring. Look for ways to improve your management systems, operating methods, and procedures to not only eliminate your current problem, but stop similar problems from developing later on.

![qa workbook the problem solving approach [inline illustration] D7 Preventive measure (example)](https://assets.asana.biz/transform/cdd7b133-fb80-4db7-8935-1285a6b62b69/inline-productivity-8d-template-9-2x?io=transform:fill,width:2560&format=webp)

Based on our example, the training your team suggested is now adopted in the new manager onboarding curriculum. Every manager now has a “meeting system” that all meetings must be guided by, and workloads and projects are managed as a team within your new collaboration software . Innovation is improving, and morale is at an all-time high!

D8: Celebrate with your team

The 8D method of problem-solving is impossible to accomplish without dedicated team members and first-class collaboration. Once notes, lessons, research, and test data are documented and saved, congratulate your teammates on a job well done! Make an effort to recognize each individual for their contribution to uncovering a successful solution.

![qa workbook the problem solving approach [inline illustration] 8D Team congratulations & reward (example)](https://assets.asana.biz/transform/d2055965-bf3d-4bf4-a1ea-a0a7c4bf8a32/inline-productivity-8d-template-10-2x?io=transform:fill,width:2560&format=webp)

8D report template and example